START-UP PROCEDURE

PRE-START PREPARATION

Before starting the pressure washer, check for loose or missing parts and for any damage which may have occurred during shipment.

PUMP PREPARATION

The pump is shipped with a shipping plug, this will need to be replaced with the vent plug that is supplied.

START-UP PROCEDURE

1.Make sure water supply is connected and turned on.

2.Release gun safety if locked.

3.To allow air to escape from the hose, squeeze trigger on the gun until there is a steady stream of water coming from the nozzle.

4.Remove any dirt or foreign matter from the gun outlet and the male connector of the wand.

5.Insert the nozzle wand into the gun and tighten the fitting securely.

6.Place the throttle in the HI position.

STARTING THE ENGINE

1.Check oil and fuel level.

2.Adjust choke, prime as necessary.

3.Set the engine switch to the “ON” position.

4.Squeeze trigger on pressure washer to release pressure while pulling on the engine starter rope with a fast steady pull. Pressure may otherwise build up making starting the unit difficult.

5.As the engine warms up, readjust the choke.

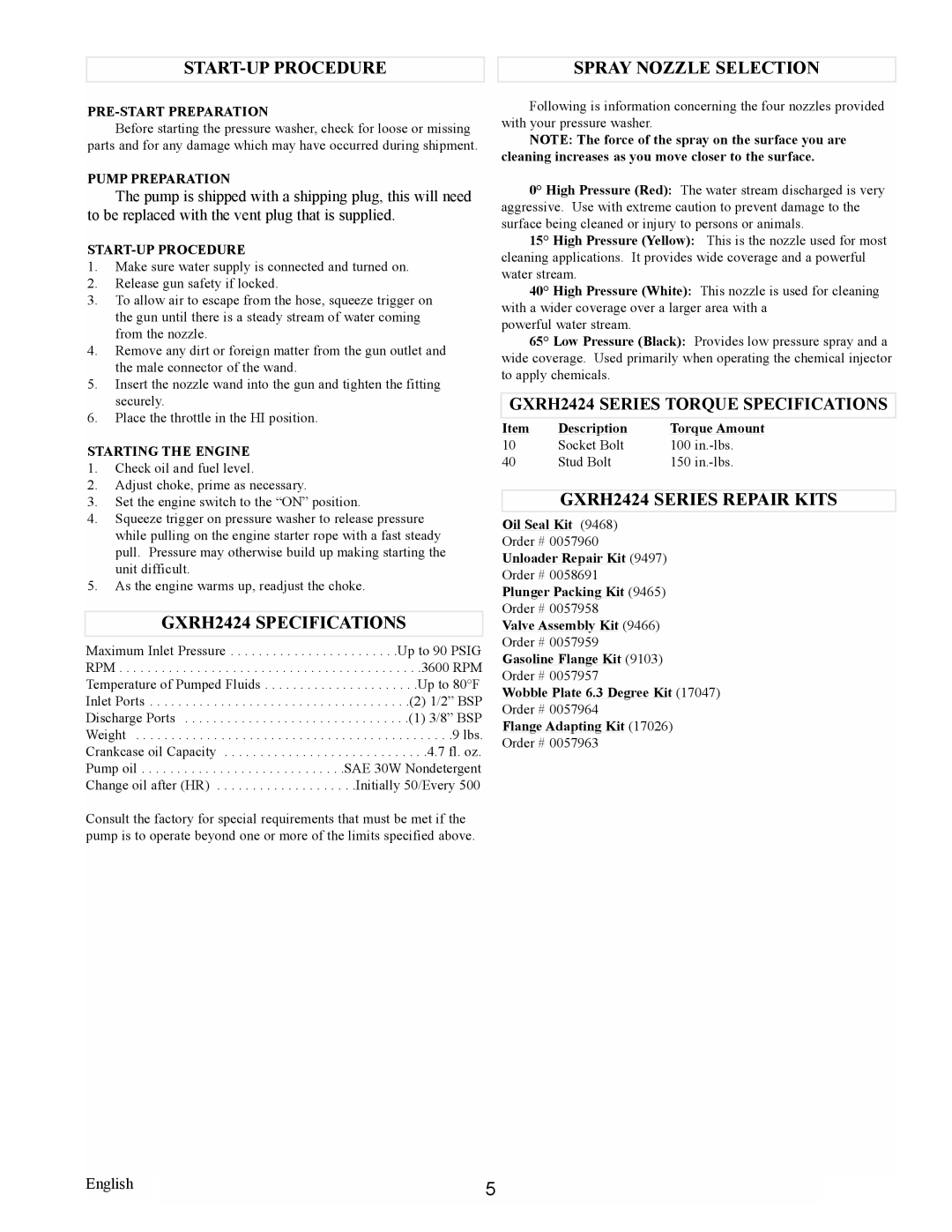

GXRH2424 SPECIFICATIONS

Maximum Inlet Pressure . . . . . . . . . . . . . . . . . . . . . . . .Up to 90 PSIG RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3600 RPM Temperature of Pumped Fluids . . . . . . . . . . . . . . . . . . . . . .Up to 80°F Inlet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(2) 1/2” BSP Discharge Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(1) 3/8” BSP Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 lbs. Crankcase oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.7 fl. oz. Pump oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SAE 30W Nondetergent Change oil after (HR) . . . . . . . . . . . . . . . . . . . .Initially 50/Every 500

Consult the factory for special requirements that must be met if the pump is to operate beyond one or more of the limits specified above.

SPRAY NOZZLE SELECTION

Following is information concerning the four nozzles provided with your pressure washer.

NOTE: The force of the spray on the surface you are cleaning increases as you move closer to the surface.

0° High Pressure (Red): The water stream discharged is very aggressive. Use with extreme caution to prevent damage to the surface being cleaned or injury to persons or animals.

15° High Pressure (Yellow): This is the nozzle used for most cleaning applications. It provides wide coverage and a powerful water stream.

40° High Pressure (White): This nozzle is used for cleaning with a wider coverage over a larger area with a

powerful water stream.

65° Low Pressure (Black): Provides low pressure spray and a wide coverage. Used primarily when operating the chemical injector to apply chemicals.

GXRH2424 SERIES TORQUE SPECIFICATIONS

| Item |

| Description | Torque Amount | ||

| 10 |

| Socket Bolt |

| 100 |

|

40 |

| Stud Bolt | 150 | |||

GXRH2424 SERIES REPAIR KITS

Oil Seal Kit (9468)

Order # 0057960

Unloader Repair Kit (9497)

Order # 0058691

Plunger Packing Kit (9465)

Order # 0057958

Valve Assembly Kit (9466)

Order # 0057959

Gasoline Flange Kit (9103)

Order # 0057957

Wobble Plate 6.3 Degree Kit (17047)

Order # 0057964

Flange Adapting Kit (17026)

Order # 0057963

|

|

|

English |

| |

5 | ||

|

|

|