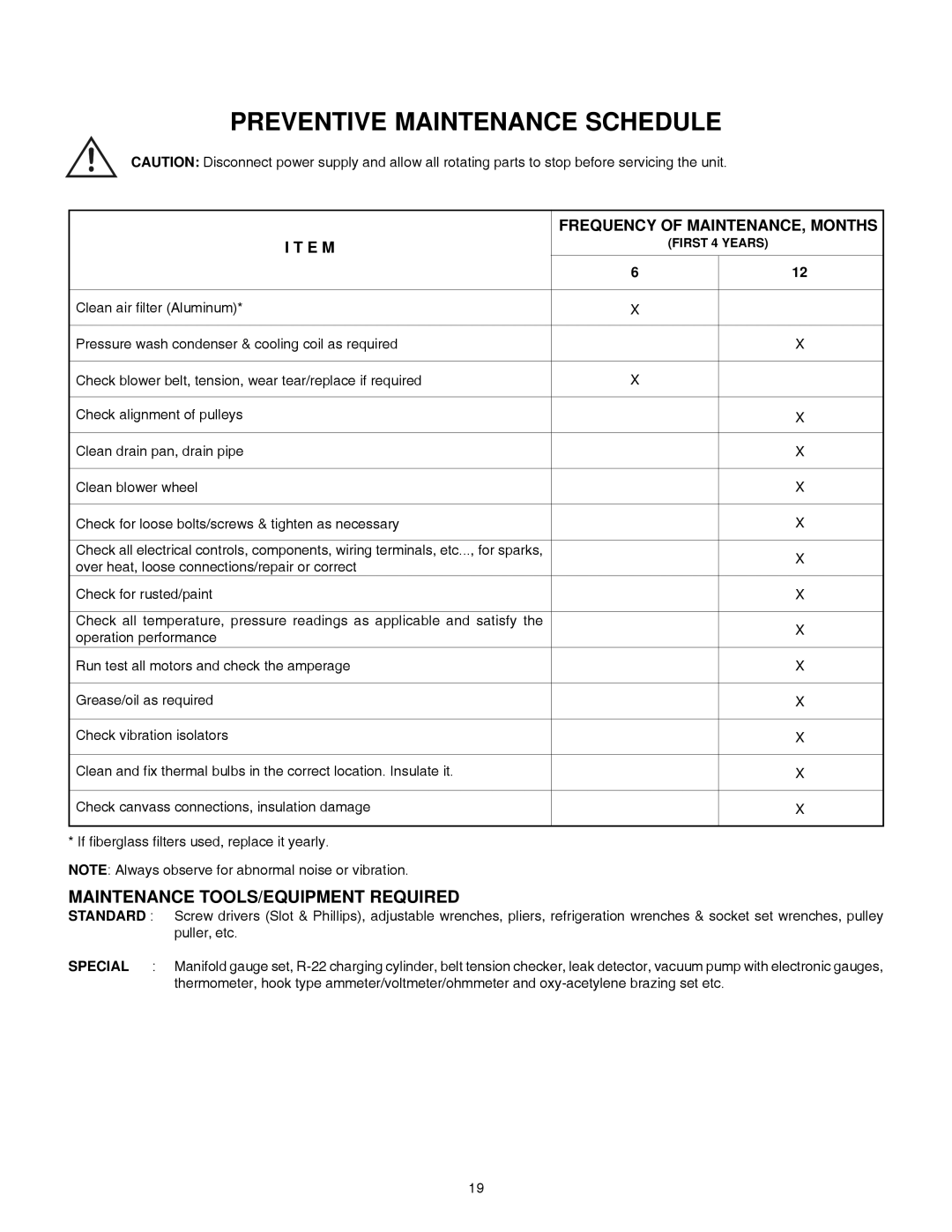

PREVENTIVE MAINTENANCE SCHEDULE

CAUTION: Disconnect power supply and allow all rotating parts to stop before servicing the unit.

|

| FREQUENCY OF MAINTENANCE, MONTHS | ||

I T E M |

| (FIRST 4 YEARS) | ||

|

| 6 |

| 12 |

|

|

|

|

|

Clean air filter (Aluminum)* | X |

|

| |

|

|

|

|

|

Pressure wash condenser & cooling coil as required |

|

| X | |

|

|

|

|

|

Check blower belt, tension, wear tear/replace if required | X |

|

| |

|

|

|

|

|

Check alignment of pulleys |

|

| X | |

|

|

|

|

|

Clean drain pan, drain pipe |

|

| X | |

|

|

|

|

|

Clean blower wheel |

|

| X | |

|

|

|

|

|

Check for loose bolts/screws & tighten as necessary |

|

| X | |

|

|

|

|

|

Check all electrical controls, components, wiring terminals, etc..., for sparks, |

|

| X | |

over heat, loose connections/repair or correct |

|

| ||

|

|

| ||

Check for rusted/paint |

|

| X | |

|

|

|

|

|

Check all temperature, pressure readings as applicable and satisfy the |

|

| X | |

operation performance |

|

| ||

|

|

| ||

|

|

|

|

|

Run test all motors and check the amperage |

|

| X | |

|

|

|

|

|

Grease/oil as required |

|

| X | |

|

|

|

|

|

Check vibration isolators |

|

| X | |

|

|

|

|

|

Clean and fix thermal bulbs in the correct location. Insulate it. |

|

| X | |

|

|

|

|

|

Check canvass connections, insulation damage |

|

| X | |

|

|

|

|

|

* If fiberglass filters used, replace it yearly. |

|

|

| |

NOTE: Always observe for abnormal noise or vibration. |

|

|

| |

MAINTENANCE TOOLS/EQUIPMENT REQUIRED

STANDARD : Screw drivers (Slot & Phillips), adjustable wrenches, pliers, refrigeration wrenches & socket set wrenches, pulley puller, etc.

SPECIAL : Manifold gauge set,

19