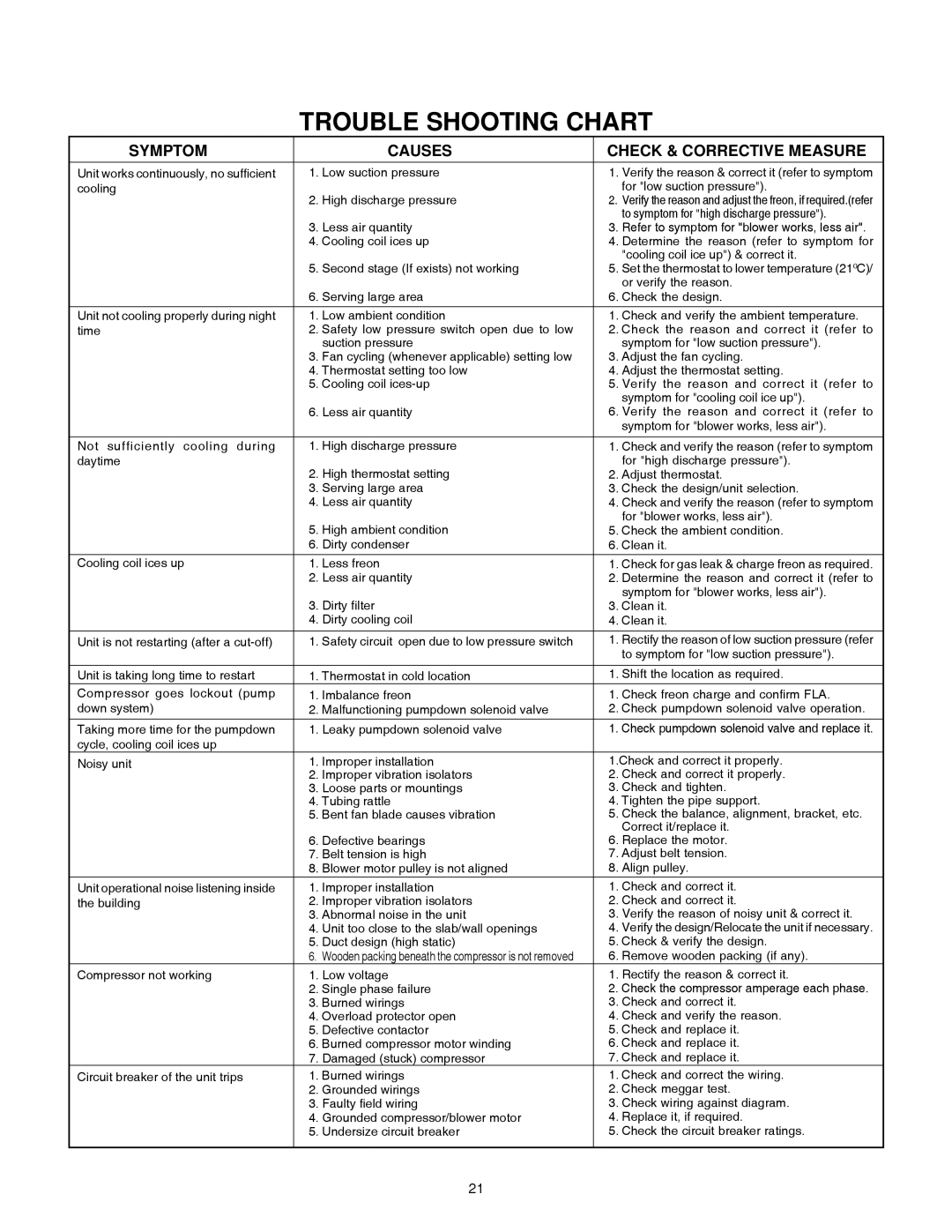

TROUBLE SHOOTING CHART

SYMPTOM |

| CAUSES | CHECK & CORRECTIVE MEASURE | |

Unit works continuously, no sufficient | 1. | Low suction pressure | 1. Verify the reason & correct it (refer to symptom | |

cooling |

|

|

| for "low suction pressure"). |

| 2. | High discharge pressure | 2. | Verify the reason and adjust the freon, if required.(refer |

|

|

|

| to symptom for "high discharge pressure"). |

| 3. | Less air quantity | 3. | Refer to symptom for "blower works, less air". |

| 4. | Cooling coil ices up | 4. Determine the reason (refer to symptom for | |

|

|

|

| "cooling coil ice up") & correct it. |

| 5. | Second stage (If exists) not working | 5. Set the thermostat to lower temperature (210C)/ | |

|

|

|

| or verify the reason. |

| 6. | Serving large area | 6. Check the design. | |

|

|

|

| |

Unit not cooling properly during night | 1. | Low ambient condition | 1. Check and verify the ambient temperature. | |

time | 2. Safety low pressure switch open due to low | 2. Check the reason and correct it (refer to | ||

|

| suction pressure |

| symptom for "low suction pressure"). |

| 3. | Fan cycling (whenever applicable) setting low | 3. Adjust the fan cycling. | |

| 4. | Thermostat setting too low | 4. Adjust the thermostat setting. | |

| 5. | Cooling coil | 5. Verify the reason and correct it (refer to | |

|

|

|

| symptom for "cooling coil ice up"). |

| 6. | Less air quantity | 6. Verify the reason and correct it (refer to | |

|

|

|

| symptom for "blower works, less air"). |

|

|

| ||

Not sufficiently cooling during | 1. High discharge pressure | 1. Check and verify the reason (refer to symptom | ||

daytime | 2. | High thermostat setting |

| for "high discharge pressure"). |

| 2. Adjust thermostat. | |||

| 3. | Serving large area | 3. Check the design/unit selection. | |

| 4. | Less air quantity | 4. Check and verify the reason (refer to symptom | |

| 5. | High ambient condition |

| for "blower works, less air"). |

| 5. Check the ambient condition. | |||

| 6. | Dirty condenser | 6. Clean it. | |

|

|

|

| |

Cooling coil ices up | 1. | Less freon | 1. Check for gas leak & charge freon as required. | |

| 2. | Less air quantity | 2. Determine the reason and correct it (refer to | |

| 3. | Dirty filter |

| symptom for "blower works, less air"). |

| 3. | Clean it. | ||

| 4. | Dirty cooling coil | 4. | Clean it. |

|

|

|

|

|

Unit is not restarting (after a | 1. | Safety circuit open due to low pressure switch | 1. | Rectify the reason of low suction pressure (refer |

|

|

|

| to symptom for "low suction pressure"). |

|

|

|

|

|

Unit is taking long time to restart | 1. | Thermostat in cold location | 1. | Shift the location as required. |

Compressor goes lockout (pump | 1. Imbalance freon | 1. Check freon charge and confirm FLA. | ||

down system) | 2. Malfunctioning pumpdown solenoid valve | 2. Check pumpdown solenoid valve operation. | ||

|

|

|

| |

Taking more time for the pumpdown | 1. Leaky pumpdown solenoid valve | 1. | Check pumpdown solenoid valve and replace it. | |

cycle, cooling coil ices up |

|

|

|

|

Noisy unit | 1. | Improper installation | 1.Check and correct it properly. | |

| 2. | Improper vibration isolators | 2. | Check and correct it properly. |

| 3. Loose parts or mountings | 3. Check and tighten. | ||

| 4. | Tubing rattle | 4. Tighten the pipe support. | |

| 5. | Bent fan blade causes vibration | 5. Check the balance, alignment, bracket, etc. | |

|

|

|

| Correct it/replace it. |

| 6. | Defective bearings | 6. Replace the motor. | |

| 7. | Belt tension is high | 7. | Adjust belt tension. |

| 8. | Blower motor pulley is not aligned | 8. | Align pulley. |

Unit operational noise listening inside | 1. | Improper installation | 1. | Check and correct it. |

the building | 2. | Improper vibration isolators | 2. | Check and correct it. |

| 3. | Abnormal noise in the unit | 3. | Verify the reason of noisy unit & correct it. |

| 4. | Unit too close to the slab/wall openings | 4. Verify the design/Relocate the unit if necessary. | |

| 5. | Duct design (high static) | 5. Check & verify the design. | |

| 6. | Wooden packing beneath the compressor is not removed | 6. Remove wooden packing (if any). | |

Compressor not working | 1. | Low voltage | 1. Rectify the reason & correct it. | |

| 2. Single phase failure | 2. | Check the compressor amperage each phase. | |

| 3. | Burned wirings | 3. Check and correct it. | |

| 4. Overload protector open | 4. Check and verify the reason. | ||

| 5. | Defective contactor | 5. Check and replace it. | |

| 6. Burned compressor motor winding | 6. Check and replace it. | ||

| 7. Damaged (stuck) compressor | 7. Check and replace it. | ||

Circuit breaker of the unit trips | 1. | Burned wirings | 1. Check and correct the wiring. | |

| 2. Grounded wirings | 2. Check meggar test. | ||

| 3. | Faulty field wiring | 3. Check wiring against diagram. | |

| 4. | Grounded compressor/blower motor | 4. Replace it, if required. | |

| 5. | Undersize circuit breaker | 5. | Check the circuit breaker ratings. |

|

|

|

|

|

21