Safety Recommendations

wrist trauma. Since they vary widely in design, material, thickness, vibration reduction, and wrist support qualities, it is recommended that the glove, tool wrap, or wrist support manufacturer be consulted for items designed for your specific application. WARNING! Proper fit of gloves is important. Improperly fitted gloves may restrict blood flow to the fingers and can substantially reduce grip strength.

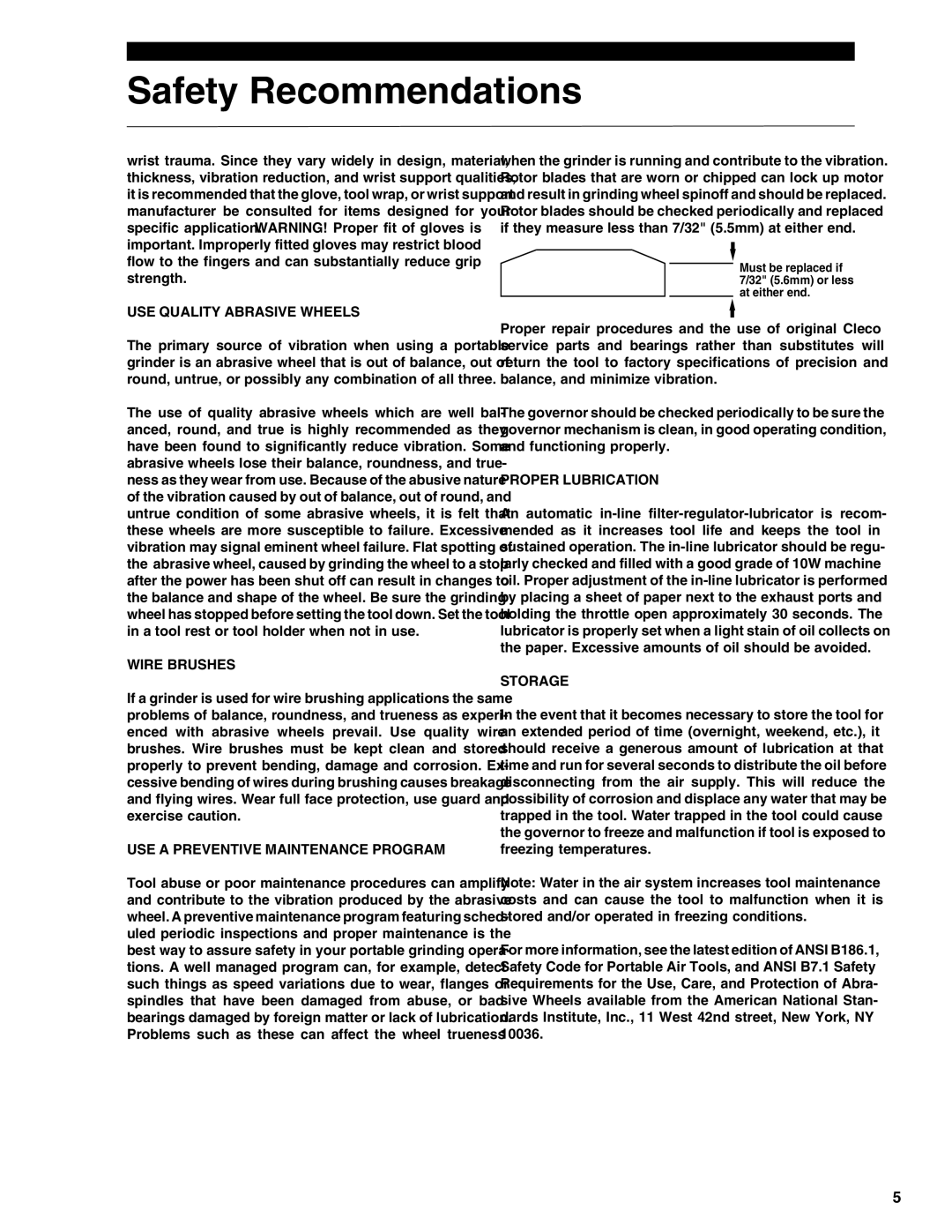

when the grinder is running and contribute to the vibration. Rotor blades that are worn or chipped can lock up motor and result in grinding wheel spinoff and should be replaced. Rotor blades should be checked periodically and replaced if they measure less than 7/32" (5.5mm) at either end.

Must be replaced if 7/32" (5.6mm) or less at either end.

USE QUALITY ABRASIVE WHEELS

The primary source of vibration when using a portable grinder is an abrasive wheel that is out of balance, out of round, untrue, or possibly any combination of all three.

The use of quality abrasive wheels which are well bal- anced, round, and true is highly recommended as they have been found to significantly reduce vibration. Some abrasive wheels lose their balance, roundness, and true- ness as they wear from use. Because of the abusive nature of the vibration caused by out of balance, out of round, and untrue condition of some abrasive wheels, it is felt that these wheels are more susceptible to failure. Excessive vibration may signal eminent wheel failure. Flat spotting of the abrasive wheel, caused by grinding the wheel to a stop after the power has been shut off can result in changes to the balance and shape of the wheel. Be sure the grinding wheel has stopped before setting the tool down. Set the tool in a tool rest or tool holder when not in use.

WIRE BRUSHES

If a grinder is used for wire brushing applications the same problems of balance, roundness, and trueness as experi- enced with abrasive wheels prevail. Use quality wire brushes. Wire brushes must be kept clean and stored properly to prevent bending, damage and corrosion. Ex- cessive bending of wires during brushing causes breakage and flying wires. Wear full face protection, use guard and exercise caution.

USE A PREVENTIVE MAINTENANCE PROGRAM

Tool abuse or poor maintenance procedures can amplify and contribute to the vibration produced by the abrasive wheel. A preventive maintenance program featuring sched- uled periodic inspections and proper maintenance is the best way to assure safety in your portable grinding opera- tions. A well managed program can, for example, detect such things as speed variations due to wear, flanges or spindles that have been damaged from abuse, or bad bearings damaged by foreign matter or lack of lubrication. Problems such as these can affect the wheel trueness

Proper repair procedures and the use of original Cleco service parts and bearings rather than substitutes will return the tool to factory specifications of precision and balance, and minimize vibration.

The governor should be checked periodically to be sure the governor mechanism is clean, in good operating condition, and functioning properly.

PROPER LUBRICATION

An automatic

STORAGE

In the event that it becomes necessary to store the tool for an extended period of time (overnight, weekend, etc.), it should receive a generous amount of lubrication at that time and run for several seconds to distribute the oil before disconnecting from the air supply. This will reduce the possibility of corrosion and displace any water that may be trapped in the tool. Water trapped in the tool could cause the governor to freeze and malfunction if tool is exposed to freezing temperatures.

Note: Water in the air system increases tool maintenance costs and can cause the tool to malfunction when it is stored and/or operated in freezing conditions.

For more information, see the latest edition of ANSI B186.1, Safety Code for Portable Air Tools, and ANSI B7.1 Safety Requirements for the Use, Care, and Protection of Abra- sive Wheels available from the American National Stan- dards Institute, Inc., 11 West 42nd street, New York, NY 10036.

5