Continuous Flow Icemaker Service Manual

MOTOR CHECK

The resistance readings on the winding will be between 5 to 25 ohms. A meter capable of these low readings must be used. The start relay cover must be removed.

If no continuity on start or run winding test, replace gearmotor. If continuity on grounded motor test, replace gearmotor.

START RELAY

1.Check between “2” and “4” on relay (with relay unplugged). If there is continuity replace the relay, as the relay contacts should be open.

2.Check between “3” and “4” on relay, if no continuity replace the relay.

FIGURE 14. GEARMOTOR ASSEMBLY

TO REPLACE GEARMOTOR ASSEMBLY

1.Disconnect the icemaker from the electrical power source.

2.Disconnect the transmission cable from the electrical box.

3.Remove the 4 hex head bolts securing the evaporator to the top of the transmission.

4.Remove the 4 bolt’s holding the transmission and bracket to frame base, while supporting the weight of the evaporator. Remove the transmission from the unit.

5.When replacing the transmission, it may be necessary to rotate the auger back and forth to align the motor shaft and auger.

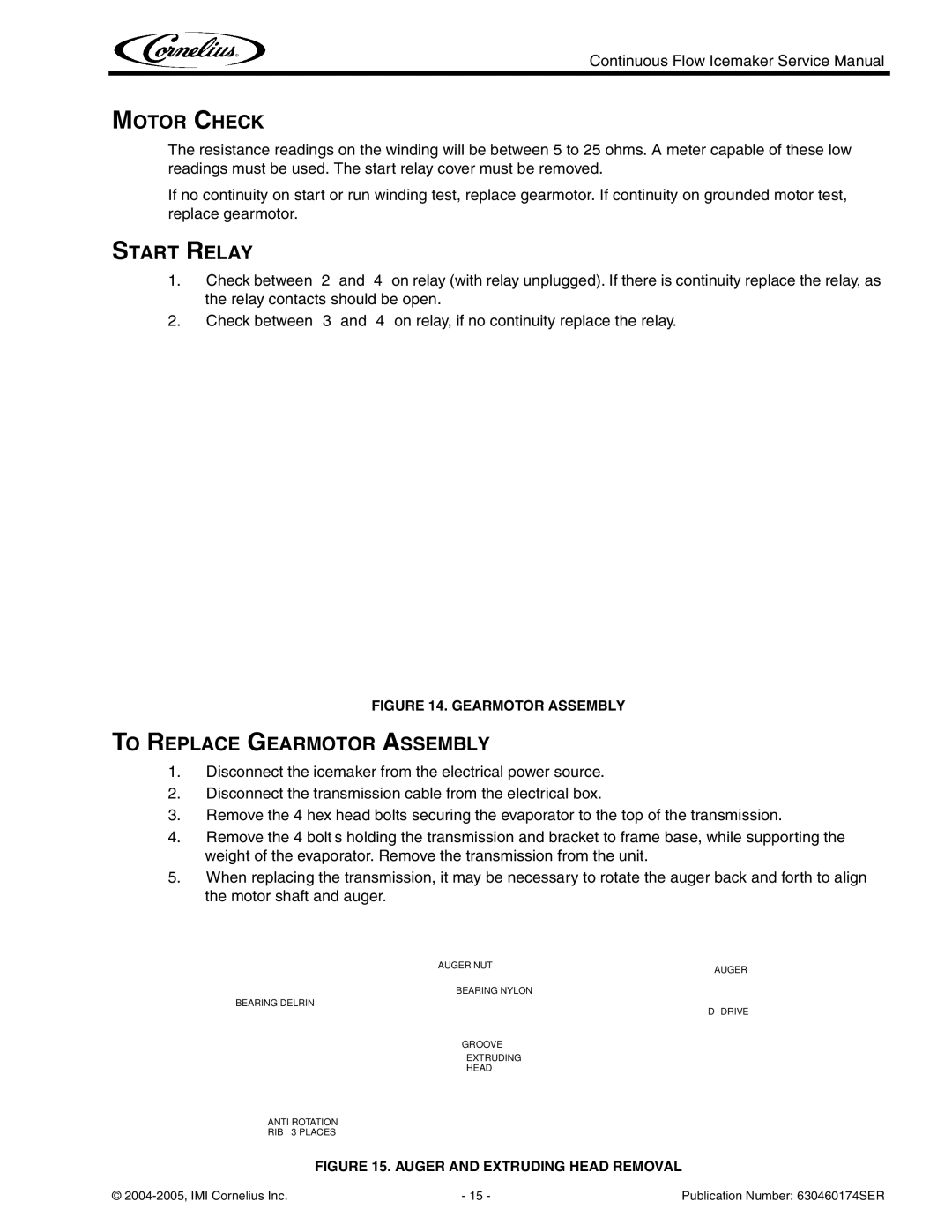

AUGER NUT | AUGER |

|

BEARING NYLON

BEARING DELRIN

“D” DRIVE

GROOVE

EXTRUDING

HEAD

RIB – 3 PLACES

FIGURE 15. AUGER AND EXTRUDING HEAD REMOVAL

© | - 15 - | Publication Number: 630460174SER |