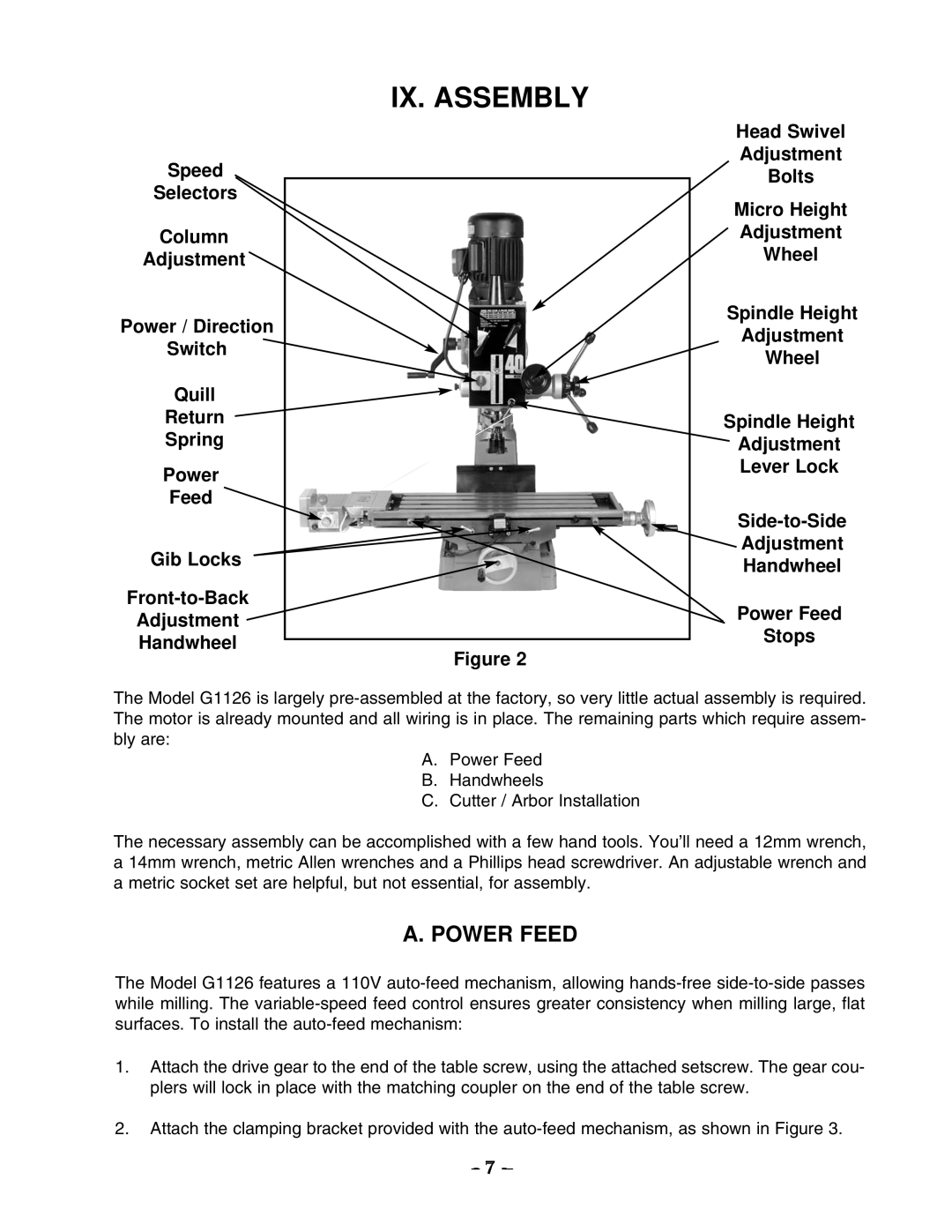

IX. ASSEMBLY

Speed

Selectors

Column

Adjustment

Power / Direction

Switch

Quill

Return

Spring

Power

Feed

Gib Locks

Adjustment

Handwheel

Figure 2

Head Swivel

Adjustment

Bolts

Micro Height

Adjustment

Wheel

Spindle Height

Adjustment

Wheel

Spindle Height

Adjustment

Lever Lock

Adjustment

Handwheel

Power Feed

Stops

The Model G1126 is largely

A.Power Feed

B.Handwheels

C.Cutter / Arbor Installation

The necessary assembly can be accomplished with a few hand tools. You’ll need a 12mm wrench, a 14mm wrench, metric Allen wrenches and a Phillips head screwdriver. An adjustable wrench and a metric socket set are helpful, but not essential, for assembly.

A. POWER FEED

The Model G1126 features a 110V

1.Attach the drive gear to the end of the table screw, using the attached setscrew. The gear cou- plers will lock in place with the matching coupler on the end of the table screw.

2.Attach the clamping bracket provided with the

- 7