F. SPINDLE HEIGHT

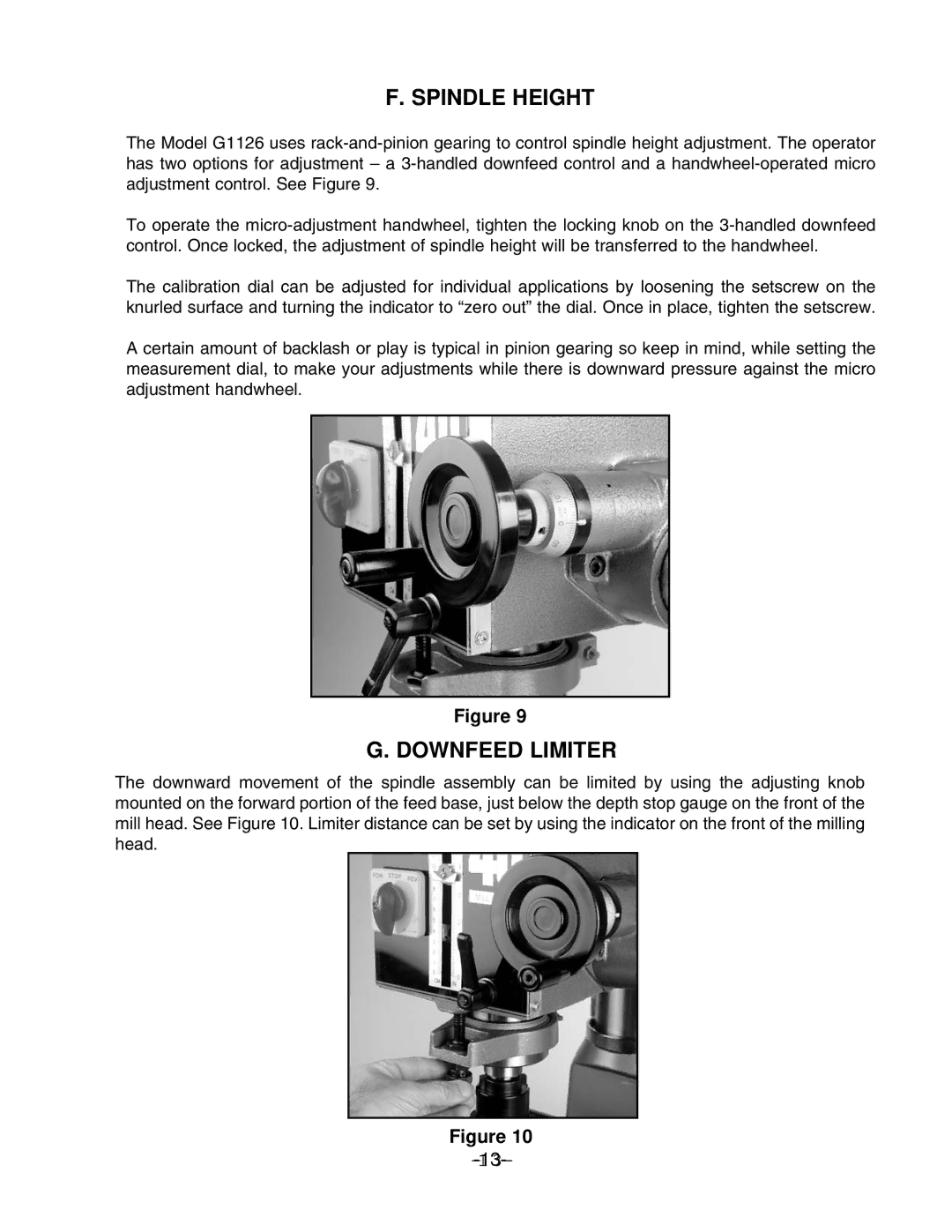

The Model G1126 uses

To operate the

The calibration dial can be adjusted for individual applications by loosening the setscrew on the knurled surface and turning the indicator to “zero out” the dial. Once in place, tighten the setscrew.

A certain amount of backlash or play is typical in pinion gearing so keep in mind, while setting the measurement dial, to make your adjustments while there is downward pressure against the micro adjustment handwheel.

Figure 9

G. DOWNFEED LIMITER

The downward movement of the spindle assembly can be limited by using the adjusting knob mounted on the forward portion of the feed base, just below the depth stop gauge on the front of the mill head. See Figure 10. Limiter distance can be set by using the indicator on the front of the milling head.

Figure 10