Establishing proper speeds for you power feed is just part of a complex equation that encompass- es a number of variables, including; spindle speed, metal hardness, feed rate, cutting depth and cut- ter type. Because of the complexity of the equations necessary to determine optimum spindle speeds and feed rates, we suggest you obtain one of many good machinist’s guides on the market. Community colleges and vocational schools are often good places to obtain informative textbooks which go into the necessary mathematics of machining in detail.

A number of fine consumer publications dealing specifically with metalworking and machining are also readily available. Check your local library or newsstand for availability in your area.

C. COLUMN HEIGHT

The Model G1126 is capable of reaching a maximum

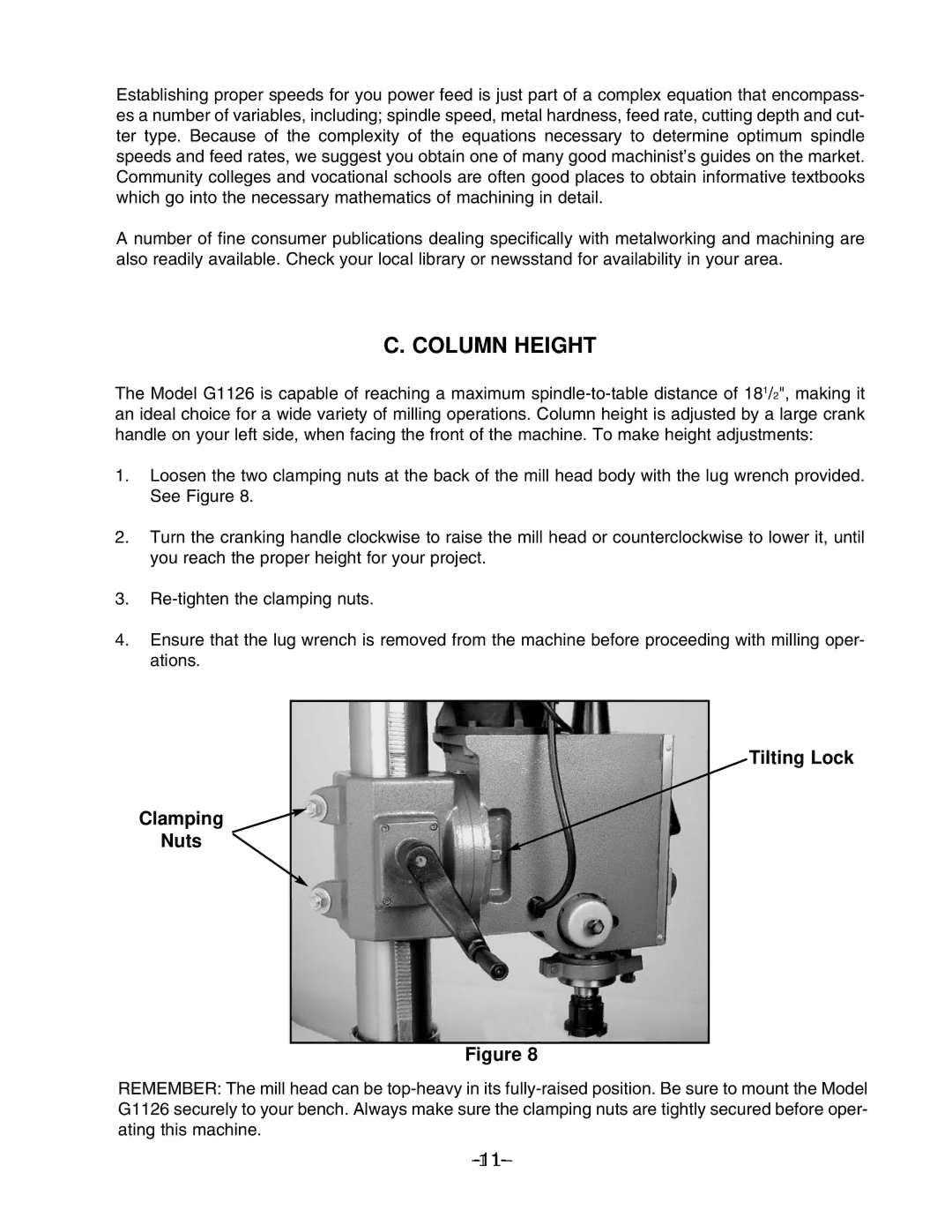

1.Loosen the two clamping nuts at the back of the mill head body with the lug wrench provided. See Figure 8.

2.Turn the cranking handle clockwise to raise the mill head or counterclockwise to lower it, until you reach the proper height for your project.

3.

4.Ensure that the lug wrench is removed from the machine before proceeding with milling oper- ations.

Clamping  Nuts

Nuts

Tilting Lock

Figure 8

REMEMBER: The mill head can be