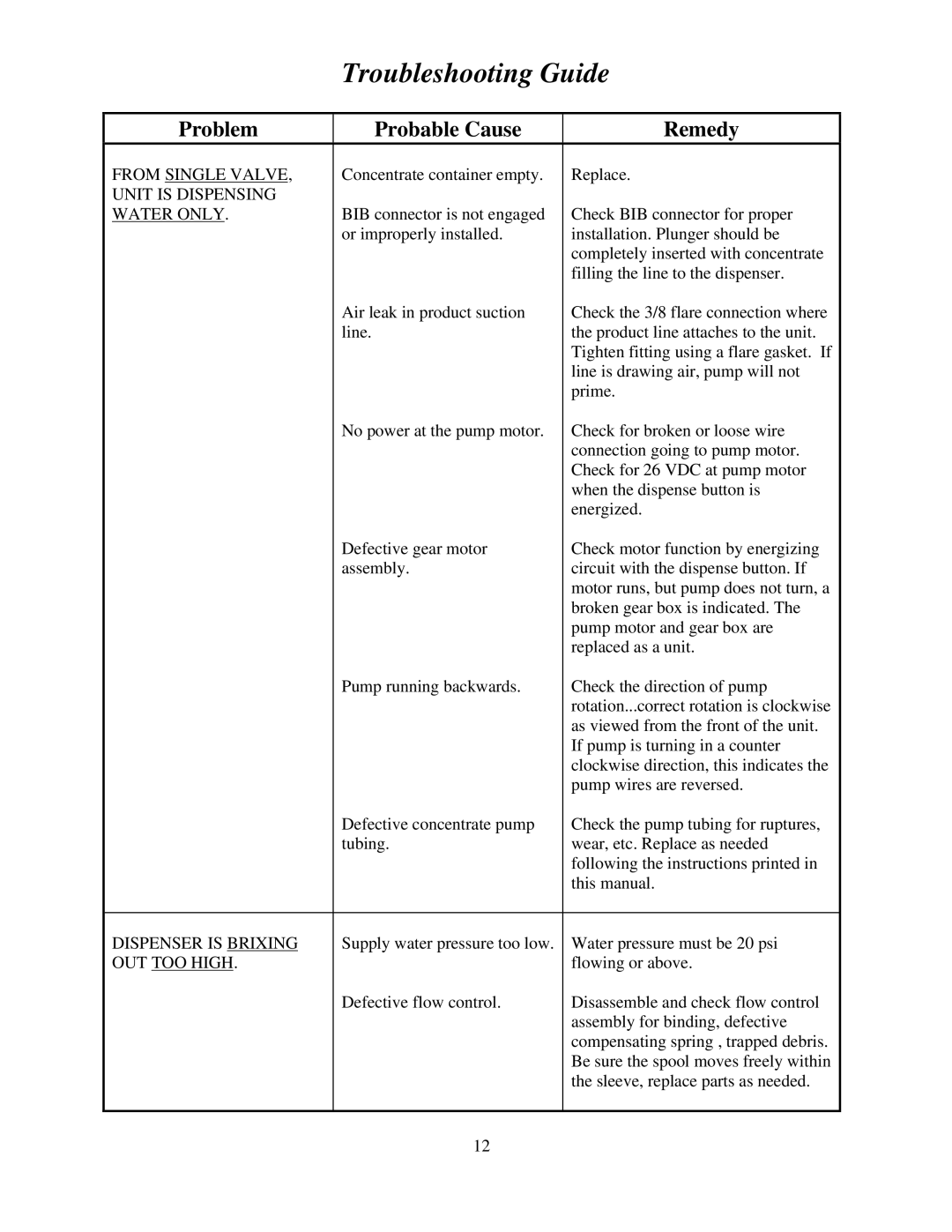

Troubleshooting Guide

Problem | Probable Cause | Remedy |

FROM SINGLE VALVE, | Concentrate container empty. | Replace. |

UNIT IS DISPENSING |

|

|

WATER ONLY. | BIB connector is not engaged | Check BIB connector for proper |

| or improperly installed. | installation. Plunger should be |

|

| completely inserted with concentrate |

|

| filling the line to the dispenser. |

| Air leak in product suction | Check the 3/8 flare connection where |

| line. | the product line attaches to the unit. |

|

| Tighten fitting using a flare gasket. If |

|

| line is drawing air, pump will not |

|

| prime. |

| No power at the pump motor. | Check for broken or loose wire |

|

| connection going to pump motor. |

|

| Check for 26 VDC at pump motor |

|

| when the dispense button is |

|

| energized. |

| Defective gear motor | Check motor function by energizing |

| assembly. | circuit with the dispense button. If |

|

| motor runs, but pump does not turn, a |

|

| broken gear box is indicated. The |

|

| pump motor and gear box are |

|

| replaced as a unit. |

| Pump running backwards. | Check the direction of pump |

|

| rotation...correct rotation is clockwise |

|

| as viewed from the front of the unit. |

|

| If pump is turning in a counter |

|

| clockwise direction, this indicates the |

|

| pump wires are reversed. |

| Defective concentrate pump | Check the pump tubing for ruptures, |

| tubing. | wear, etc. Replace as needed |

|

| following the instructions printed in |

|

| this manual. |

|

|

|

DISPENSER IS BRIXING | Supply water pressure too low. | Water pressure must be 20 psi |

OUT TOO HIGH. |

| flowing or above. |

| Defective flow control. | Disassemble and check flow control |

|

| assembly for binding, defective |

|

| compensating spring , trapped debris. |

|

| Be sure the spool moves freely within |

|

| the sleeve, replace parts as needed. |

|

|

|

12