Operators Manual

Inside Back

Service

Identification

General Operation

Ignition System

Service and Maintenance

Rotating Blades

Safety & Operation Decals

Height Adjustment

\,CRAFTSMAN

Two Bin Bagger Headlight Kit Front Bumper Kit

Setup instructions

Read The Operators

Control Functions

Hour Meter

General Operating Safety

Ignition Switch

PTO Switch

Do not stop or park rider over dry leaves, grass or

Checks Before Starting

Fuel Recommendations

Mowing

Emergency Stopping

Stopping the Rider & Engine

Starting the Engine

Levers Gradually

Forward Travel

Smooth Travel

Forward Travel Practice

Practice Turning in Place

Practice Turning Around a Corner

Executing Turns Turning In Place

Executing an End=Of=Row Zero Turn

Removing the Mower Deck

Mower Deck Removal Installation

Installing the Mower Deck

19HP Briggs & Stratton

Maintenance Schedule

All

Models

Pressure

Clean Debris from Rider and Engine Compartment

Clean Debris from Engine Cooling Areas and AIR Filter

Checktire Pressure

Arbor Lubrication 3-Blade Model Shown

Service Interval 25 hours

Blade Removal Workbench

Clean Deck Check / Replace Mower Blades

Service interval 100 Hours

Cleaning the Battery and Cables

Check Rider Safety System

Operational Safety Checks

Adjustment Nut

Check / Adjust PTO Clutch

Service interval 200 Hours

Adjustment Window Qty , one shown B. Adjustment Nut

Change Engine OIL & Filter

Check Engine OIL Level

Change Engine OIL

Air Filter Latch Air Filter Cover

AiR Filter & PRE-CLEANER

Replace Spark Plug

Air Filter Service

Pre=Cleaner Service

Ground Speed Control Lever

Adjustment

Speed Balancing Adjustment

Battery Charging

Cutting Height Adjustment

PTO Clutch Adjustment

Brake Adjustment

Side to Side Leveling

Mower Deck Leveling Adjustments

Backside idler Pulley

Mower Belt Replacement

Front To Back Leveling

STO RAG E

Troubleshooting Rider

Mower cut is

Troubleshooting

Mower

Rider will not

ZTS

Garantja Limitada DEL Equipo Montable DE Craftsman

Hardware

Transporte Y Almacenamento

Equipo RElVlOLCADO Unidades Monta

Operacion EN Cuestas

SERViCiO Y MANTENilVllENTO

Calcomania Peligro/Advertencia, inferior

Interruptor

Identificaci6n

2s u

Recolector de Hierba con Bolsa Gemela Faro delantero

Fresca

MOperador

Ahogador

Palancas de velocidad en suelo

Freno de parada

Ajuste de AJtura de Corte de Podadora

Interruptor de Encendido

Medidor de Horas

Interruptor PTO

Nunca permita que pasajeros se paseen en la unidad

Advertencia Reiviolques

Manualmente

Motor

Como Arrancar EL Motor

Manejo Hacia Manejo en Adelante

PR. ,CTICA DE Ivianejo

Traslado sin prob=

Lemas

Prctica de Vuelta en el Lugar

Prbctica de dar Vuelta en una Esquina

Ejecutar un Giro Cero al Final de la Fila

Vuelta en el Mismo Lugar

Instalar o quitar la podadora

Remocion E Instalacion DE LA Cubierta DE LA Podadora

Quitar la Cubierta de la Podadora

Instalar la Cubierta de la Podadora

Anual

Programa

DEL MONTABLE, de todos Los Antes de

Intervalo de Servicio 25 horas

TRO DE AIREA. Rejilla de Admisi6n

Aceite

LUBRICACI6N

Operacion

Para su seguridad personal, los tornillos de

Si la unidad no pasa una prueba de seguridad

Intervalo de Servicio 200 horas

VERIFICAR/AJUSTAR Embrague DEL PTO

Verifique EL Nivel DE Aceite DEL Motor

Predepurador

SERVlCIO DEL Filtro DE Airey DEL PRE

Remoci6n e instalaci6n del filtro de aire

Prepurificador Filtro de aire

Servicio del prepurificador

Servicio del filtro de aire

Reemplace LA BUJiA DE Encendido =

Pernos de Montaje Perilla

Ajuste DE Palanca DE Control

DE Velocidad

Ajustes DEL Motor

Ajuste DE LA Altura DE Corte

Ajuste DEL Embrague DEL PTO

Ajuste DEL Freno

Tuerca Exterior

Ajuste DE Nivel DE LA Cubierta DE LA Podadora

Nivelado de un Lado a Otto

Polea Derecha del Arbol de SujecJ6n

Nivelado de Adelante hacia Atrs

Advertencia

Consumo de

Diagn6stico

Del Tractor

Diagn6stico de la Podadora

RepairParts

ZTS 7500

Frame, Body & Seat Group

Footnotes

Frame Body & Seat Group

ZTS

PTS-4

REF no Part NO. QTY. Description

Frame, Body & Seat Group ZTS

Engine Group 19HP Briggs & Stratton ZTS 7500

Utch

REF no

Engine Group 19HP Briggs Stratton 987321

1618

Carrier & Transmission Group ZTS 7500

Carrier Transmission Group 987362

Frame Assembly

Carrier & Transmission Group ZTS 7500

Refno Partno QTY Description

Carrier Transmission Group

ZTS 7500

Controls Group

Refno QTY Description

Controls Group 986806

Electrical Group ZTS 7500

HeadlightSwitch Seatpan Optional

QTY Description

Electrical Group

Torque to 44 55 ft. Ibs Or 59.4 74.8 Nm PTS-16

REF no QTY Description

Decals Group D987352 987357987358986884986857987350 ZTS 7500

QTY Description

Decals Group D987352 987357987358986884986857987350

Mower Deck Clutch & Support Group

No Part no QTY Description

Mower Deck Clutch Support Group

Mower Deck Height Adjustment Group ZTS 7500

Mower Deck Height Adjustment Group 987324

Mower Deck Housing, Arbors & Blades Group ZTS 7500

Mower Deck Housing Arbors Blades Group 987322

221

868@

13J

1266A

Part Description

Engine Parts

Briggs & Stratton Engine Parts ZTS 7500 = Model No

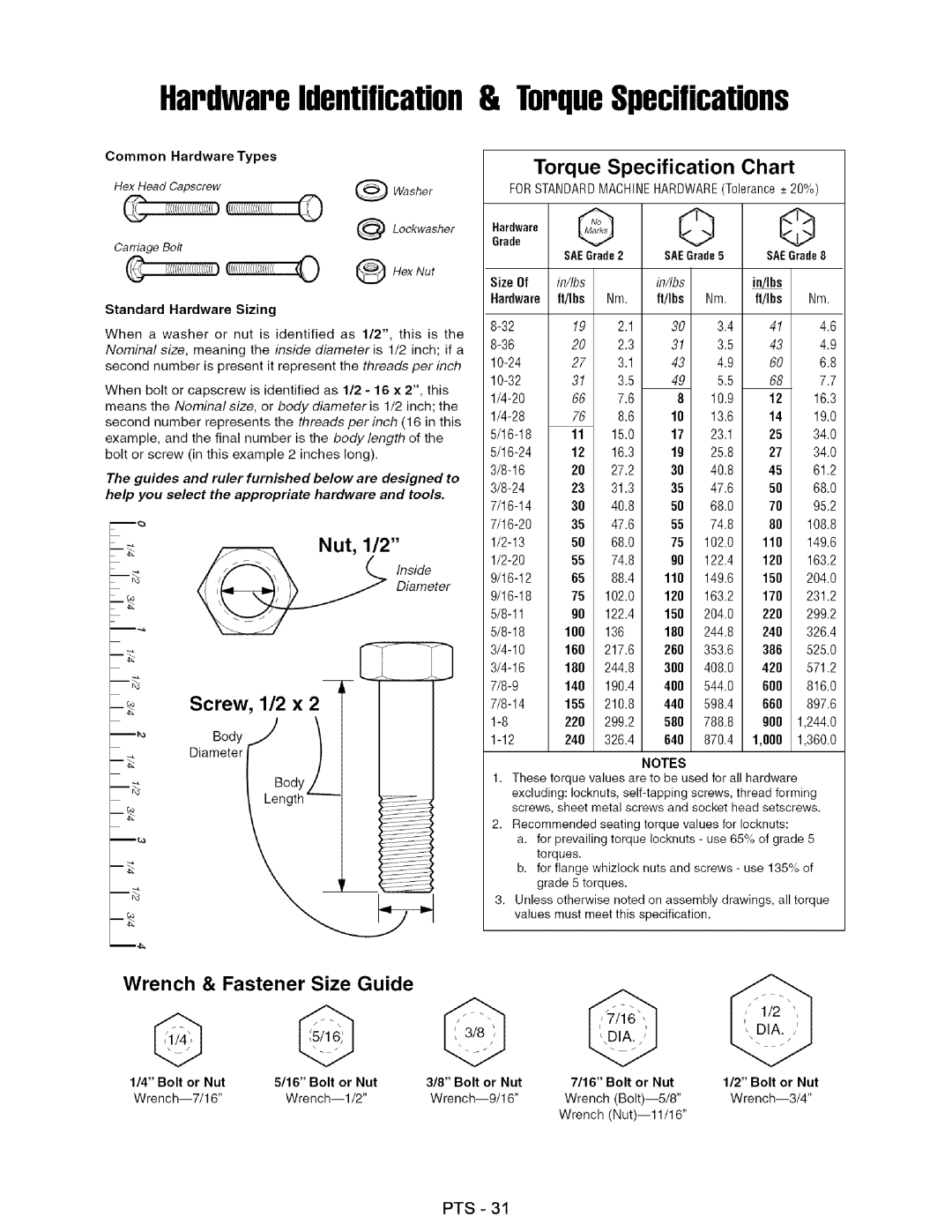

Hardware identification& TorqueSpecifications

PTS

Servicio de Jnstalaci6n de Sears

Sears Installation Service

Repair Protection Agreements

Acuerdo de Protecci6n de Reparaciones

Call anytime, day or night U.S.A. only

Call anytime, day or night U.S.A. and Canada