137.21236 specifications

The Craftsman 137.21236 is a versatile and reliable tool that caters to both DIY enthusiasts and professional craftsmen alike. Designed to deliver precision and efficiency, this saw embodies the spirit of dependable craftsmanship that the Craftsman brand is known for.One of the main features of the Craftsman 137.21236 is its robust and powerful motor. With a solid horsepower rating, it provides ample cutting power, making it ideal for a variety of woodworking tasks, including ripping, cross-cutting, and bevel cuts. This powerful motor allows users to effortlessly cut through different materials, including hardwoods, softwoods, and engineered wood products, ensuring versatility in various projects.

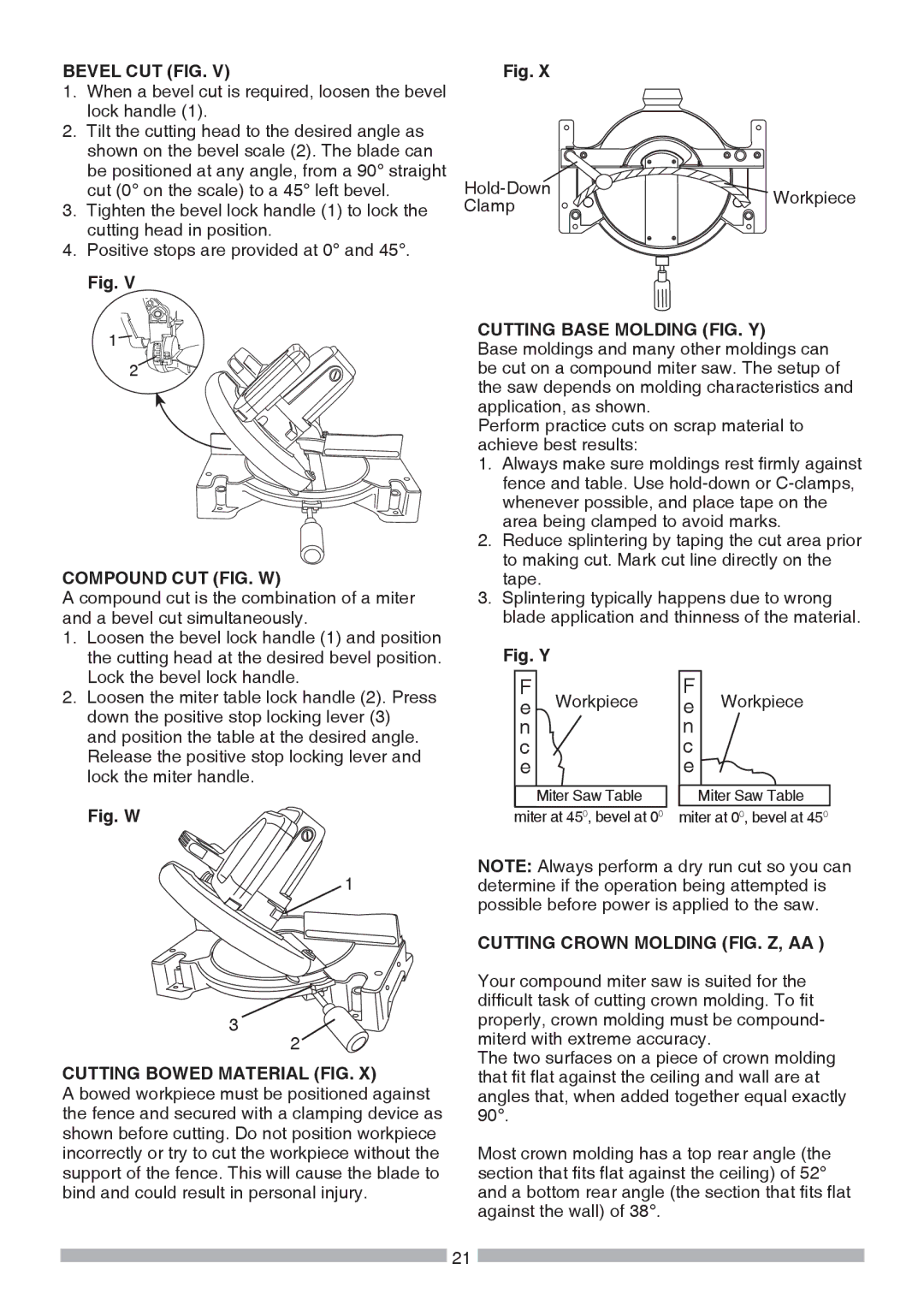

Another significant characteristic is its adjustable cutting depth and angle. The saw features a user-friendly bevel mechanism, allowing for precise adjustment of the cutting angle up to 45 degrees. This feature enhances usability when tackling angled cuts, dovetails, or compound miter cuts. Moreover, the cutting depth can be easily modified, enabling users to manage the thickness of the material being worked on, thus providing greater control and flexibility during operation.

The Craftsman 137.21236 also boasts an ergonomically designed handle, which not only improves comfort during extended use but also enhances control and reduces fatigue. The balanced weight distribution of the tool ensures stability, minimizing vibrations during operation for precise cuts.

In terms of safety, this model is equipped with an integrated blade guard and an electric brake, ensuring that it meets the safety standards expected of high-quality power tools. The blade guard prevents accidental contact with the blade, while the electric brake halts the blade's rotation almost instantaneously when the trigger is released, enhancing user safety during operation.

Furthermore, the Craftsman 137.21236 is compatible with a range of blades, allowing users to swap out blades according to the specific needs of their projects. Whether it's a fine-tooth blade for intricate cuts or a carbide-tipped blade for heavy-duty work, the compatibility adds another layer of versatility.

In summary, the Craftsman 137.21236 is a feature-rich and technologically advanced tool that embodies reliability and precision. Its powerful motor, adjustable features, ergonomic design, and focus on safety make it a valuable addition to any workshop, catering to the diverse needs of users, whether they are tackling home renovations or professional woodworking projects.