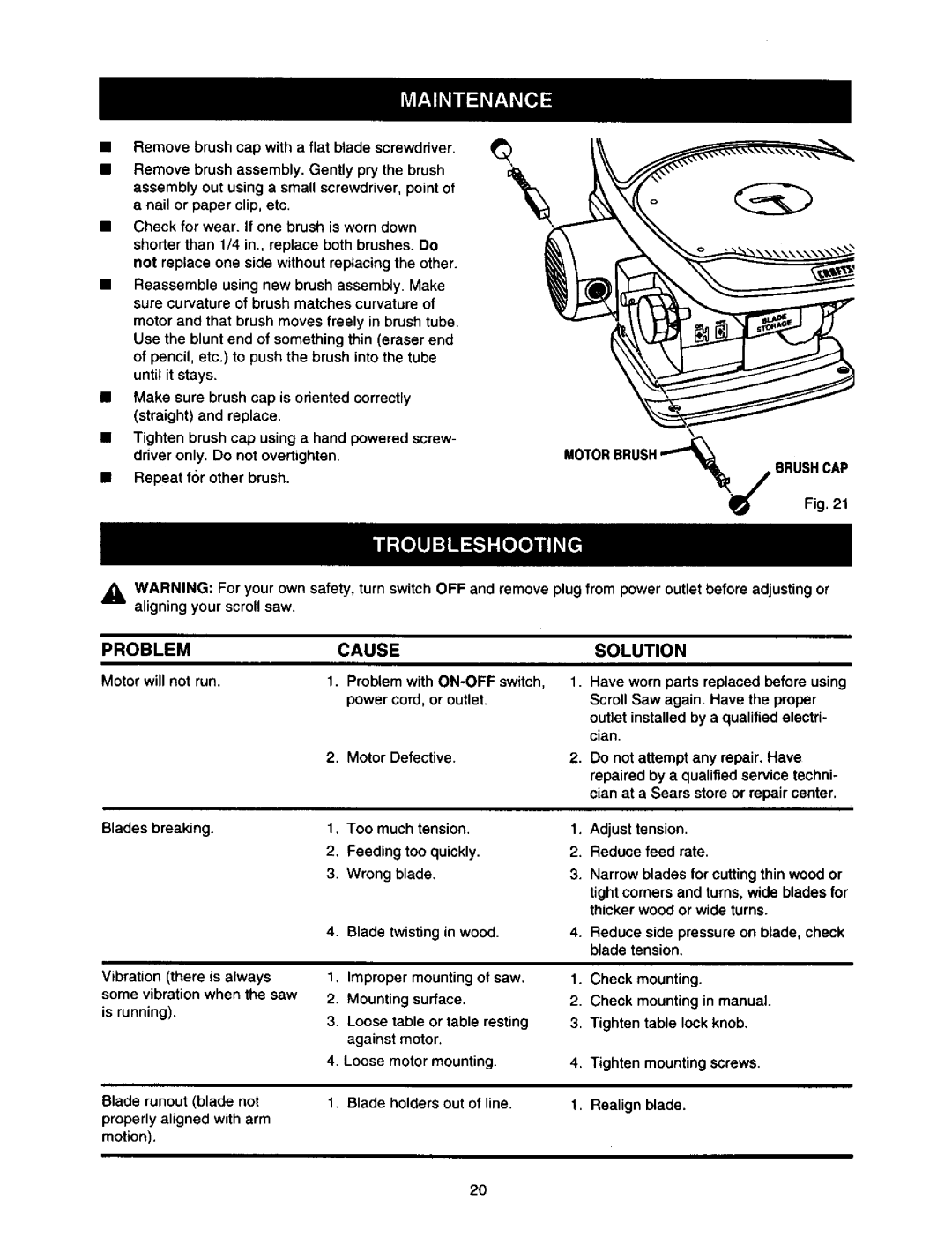

• | Remove brush cap with a flat blade screwdriver. | \ | |

• | Remove brush assembly. Gently pry the brush | ||

| assembly out using a small screwdriver, point of | ||

| a nail or paper clip, etc. |

| |

• | Check for wear. If one brush is worn down |

| |

| shorter than 1/4 in., replace both brushes. Do |

| |

| not replace one side without replacing the other. |

| |

• | Reassemble using new brush assembly. Make |

| |

| sure curvature of brush matches curvature of |

| |

| motor and that brush moves freely in brush tube. |

| |

| Use the blunt end of something thin (eraser end |

| |

| of pencil, etc.) to push the brush into the tube |

| |

| until it stays. |

|

|

• | Make sure brush cap is oriented | correctly |

|

| (straight) and replace. |

|

|

• | Tighten brush cap using a hand powered screw- |

| |

| driver only. Do not overtighten. |

| #pBRUSHCAP |

|

|

| |

•Repeat for other brush.

Fig. 21

_i, WARNING: For your own safety, turn switch OFF and remove plug from power outlet before adjusting or aligning your scroll saw.

PROBLEM | CAUSE |

Motor will not run. | 1. Problem with |

| power cord, or outlet. |

SOLUTION

1.Have worn parts replaced before using Scroll Saw again. Have the proper outlet installed by a qualified electri- cian.

|

|

|

| 2. | Motor Defective. |

| 2. | Do not attempt any repair. Have | ||||

|

|

|

|

|

|

|

|

|

| repaired by a qualified service techni- | ||

|

|

|

|

|

|

|

|

|

| cian at a Sears store or repair center. | ||

Blades breaking. |

|

| 1. Too much tension. |

| 1. | Adjust tension. |

| |||||

|

|

|

| 2. | Feeding too quickly. | 2. | Reduce feed rate. |

| ||||

|

|

|

| 3. | Wrong blade. |

| 3. | Narrow blades for cutting thin wood or | ||||

|

|

|

|

|

|

|

|

|

| tightcorners and turns, wide blades for | ||

|

|

|

|

|

|

|

|

|

| thicker wood or wide turns. | ||

|

|

|

| 4. | Blade | twisting in wood. | 4. | Reduce side pressure on blade, check | ||||

|

|

|

|

|

|

|

|

|

| blade tension. |

| |

Vibration | (there | is always | 1. | Improper | mounting | of saw. | 1. | Check | mounting. |

| ||

some vibration when the saw | 2. | Mounting | surface. |

| 2. | Check | mounting in manual. | |||||

is running). |

|

| 3, | Loose table or table resting | 3. | Tighten | table lock | knob. | ||||

|

|

|

|

| against |

| motor. |

|

|

|

|

|

|

|

|

| 4, Loose | motor mounting. | 4. | Tighten | mounting | screws. | |||

Blade runout (blade | not | 1, | Blade | holders out | of line. | 1. | Realign | blade. |

| |||

properly | aligned | with | arm |

|

|

|

|

|

|

|

|

|

motion).

20