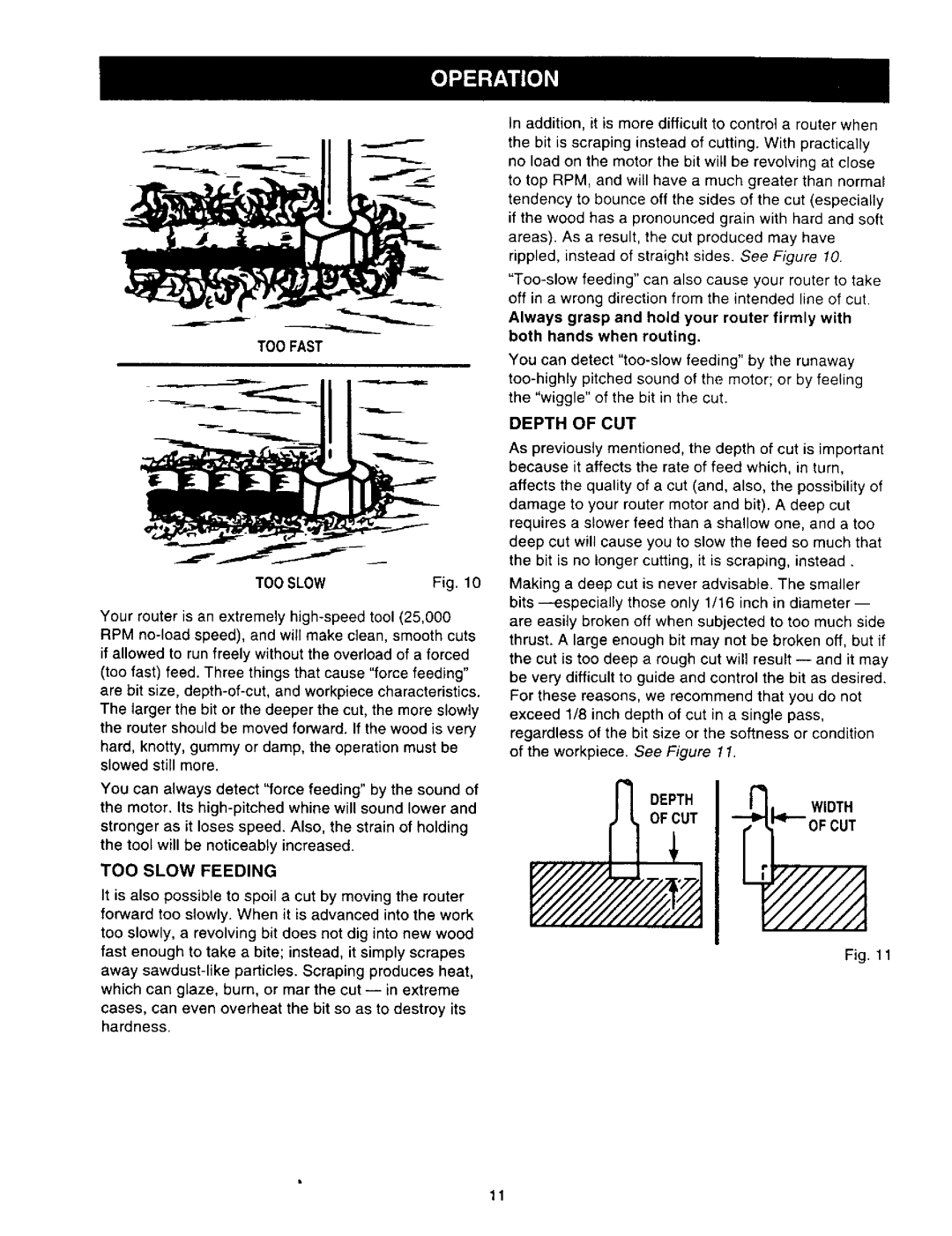

TOO FAST

Your router is an extremely high-speed tool (25,000 RPM no-load speed), and will make clean, smooth cuts if allowed to run freely without the overload of a forced (too fast) feed. Three things that cause "force feeding" are bit size, depth-of-cut, and workpiece characteristics. The larger the bit or the deeper the cut, the more slowly the router should be moved forward. If the wood is very hard, knotty, gummy or damp, the operation must be slowed still more.

You can always detect "force feeding" by the sound of the motor. Its high-pitched whine will sound lower and stronger as it loses speed. Also, the strain of holding the tool will be noticeably increased.

TOO SLOW FEEDING

It is also possible to spoil a cut by moving the router forward too slowly. When it is advanced into the work too slowly, a revolving bit does not dig into new wood fast enough to take a bite; instead, it simply scrapes away sawdust-like particles. Scraping produces heat, which can glaze, burn, or mar the cut -- in extreme

cases, can even overheat the bit so as to destroy its hardness.

tn addition, it is more difficult to control a router when

the bit is scraping instead of cutting. With practically no load on the motor the bit will be revolving at close to top RPM, and will have a much greater than normal tendency to bounce off the sides of the cut (especially if the wood has a pronounced grain with hard and soft areas). As a result, the cut produced may have rippled, instead of straight sides. See Figure 10.

"Too-slow feeding" can also cause your router to take off in a wrong direction from the intended line of cut. Always grasp and hold your router firmly with both hands when routing.

You can detect "too-slow feeding" by the runaway too-highlypitched sound of the motor; or by feeling the "wiggle" of the bit in the cut.

DEPTH OF CUT

As previously mentioned, the depth of cut is important because it affects the rate of feed which, in turn, affects the quality of a cut (and, also, the possibility of damage to your router motor and bit). A deep cut requires a slower feed than a shallow one, and a too deep cut will cause you to slow the feed so much that the bit is no longer cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller bits---especially those only 1/16 inch in diameter- are easily broken off when subjected to too much side thrust. A large enough bit may not be broken off, but if the cut is too deep a rough cut will result -- and it may be very difficult to guide and control the bit as desired. For these reasons, we recommend that you do not exceed 1/8 inch depth of cut in a single pass, regardless of the bit size or the softness or condition of the workpiece. See Figure 11.

DEPTHWIDTH

OFCUTCUT

Fig. 11