Donotforce.Theweightofthe unitsuppliesadequate

pressure.Let the sandpaper and sander do the work. Ap- plyingadditional pressuresrowa the motor, rapidlywears sandpaper and greatlyreducessander speed. Excessive pressurewill overloadthe motor causing possibledamage from motor overheatingand can result in inferiorwork.

Any finish or resin on wood maysoften from the frictional

heat. Do not allow sanding on one spot too long, as the

sander'srapid action may remove too much matarial, making the surface uneven.

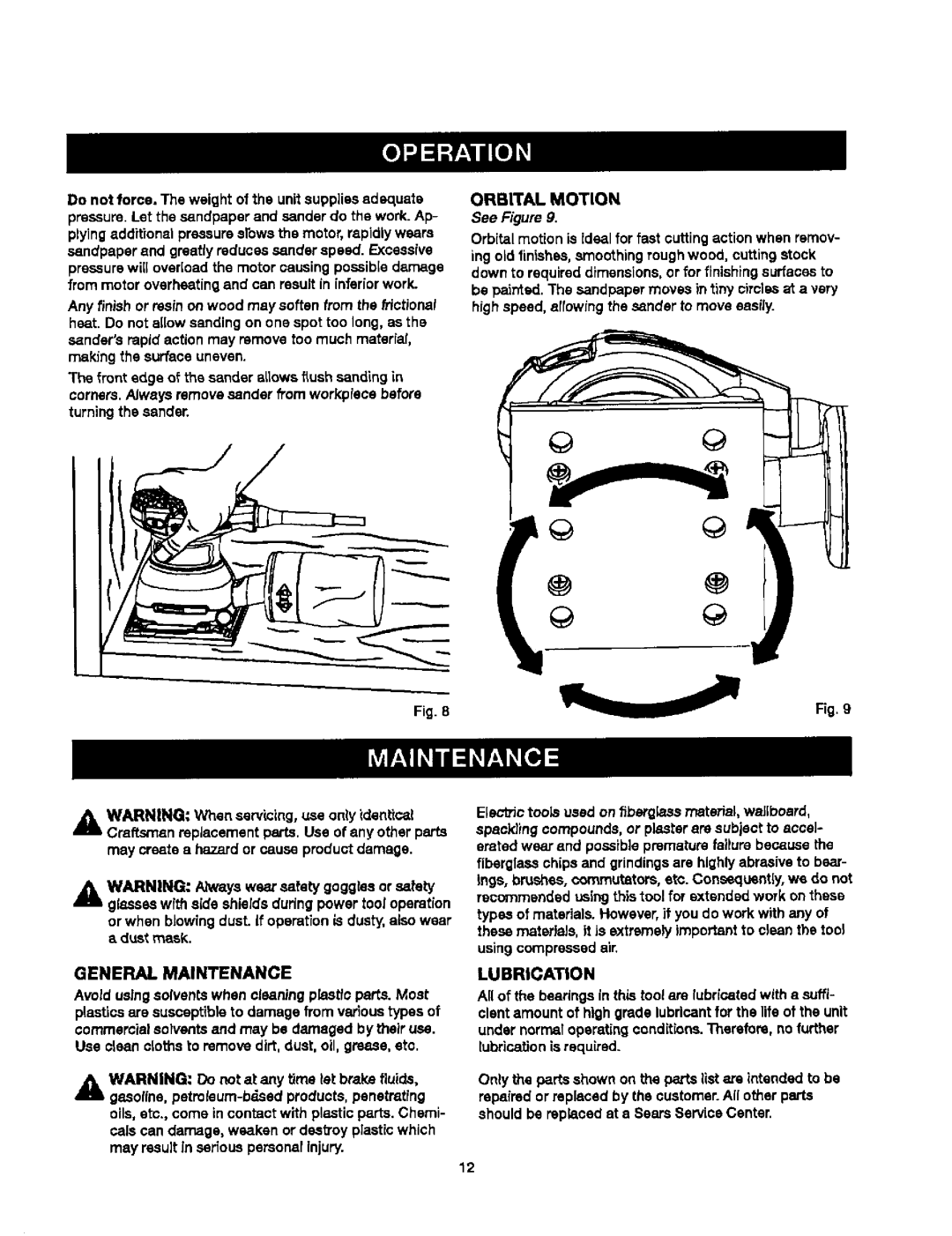

ORBITAL MOTION

See Figure 9.

Orbital motion is idealfor fast cutting actionwhen remov-

ing old finishes,smoothingroughwood, cutting stock down to required dimensions,or for finishingsurfaces to be painted. The sandpaper moves in tiny circlesat a very highspeed, arrowing the sander to move easily.

The front edge o_the sander allows ftush sandingin corners.AJwayaremove sander from workptece before turningthe sander.

Fig. 8

AWARNING: When servicing,use only identical Craftsman replacement parts. Use of any other parts may create a hazard or cause productdamage.

AWARNING: Always wear _ataty goggles or safety glasseswith side shie/ds during power tool operation

or when blowing dust. If operation is dusty,also wear a dust mask.

GENERAL MAINTENANCE

Avoid usingsolventswhen cleaning plasticparts. Most plasticsare susceptibleto damage from various types of commercialsolventsand may be damaged by their use. Use clean clothsto remove dirt, dust, oil, grease,etc.

WARNING: Do not at any time let brake fluids, gasoline,

Fig. 9

Electrictools used on flbargLseamaterial, wallboard, specklingcompounds, or plasterere subject to scsal- stated wear and possiblepremature faiturebecause the

fiberglass chipsand grindingsare highlyabrasiveto bear- ings, brushes,commutators,etc. Consequently,we do not recommended usingthis tool for extended work on these types of materials. However, it you do work with any of these materials, it is extremelyimportantto clean the tool using compressed air.

LUBRICATION

All of the bearings in this toolam lubricatedwith a suffi- cient amount of high grade lubricantfor the life of the unit under normal operating conditions.Therefore, no further lubricationis required.

Only the parts shown on the parts listare intended to be repairedor replaced by the customer.All other parts should be replaced at a Sears ServiceCenter.

12