CHECK FOR DAMAGED OR WORN PARTS

Replacementofdamaged/wornparts shouldbe referredto yourSeam Ser- vice Center.

NOTE: It is normalfor a small amount ofoil to appear underthe saw after en- gine stops.Do not confusethis with a leakingoiltank.

o On/Stop Switch- EnsureOn/Stop switchfunctions propedyby moving the switchto the "Stop"position. Make sure enginestops;then restart engine and continue.

•Fuel Tank- Do not usesaw iffuel tankshows signsofdamage or leaks.

•Oil Tank- Do not use saw ifoil tank shows signsof damage or leaks.

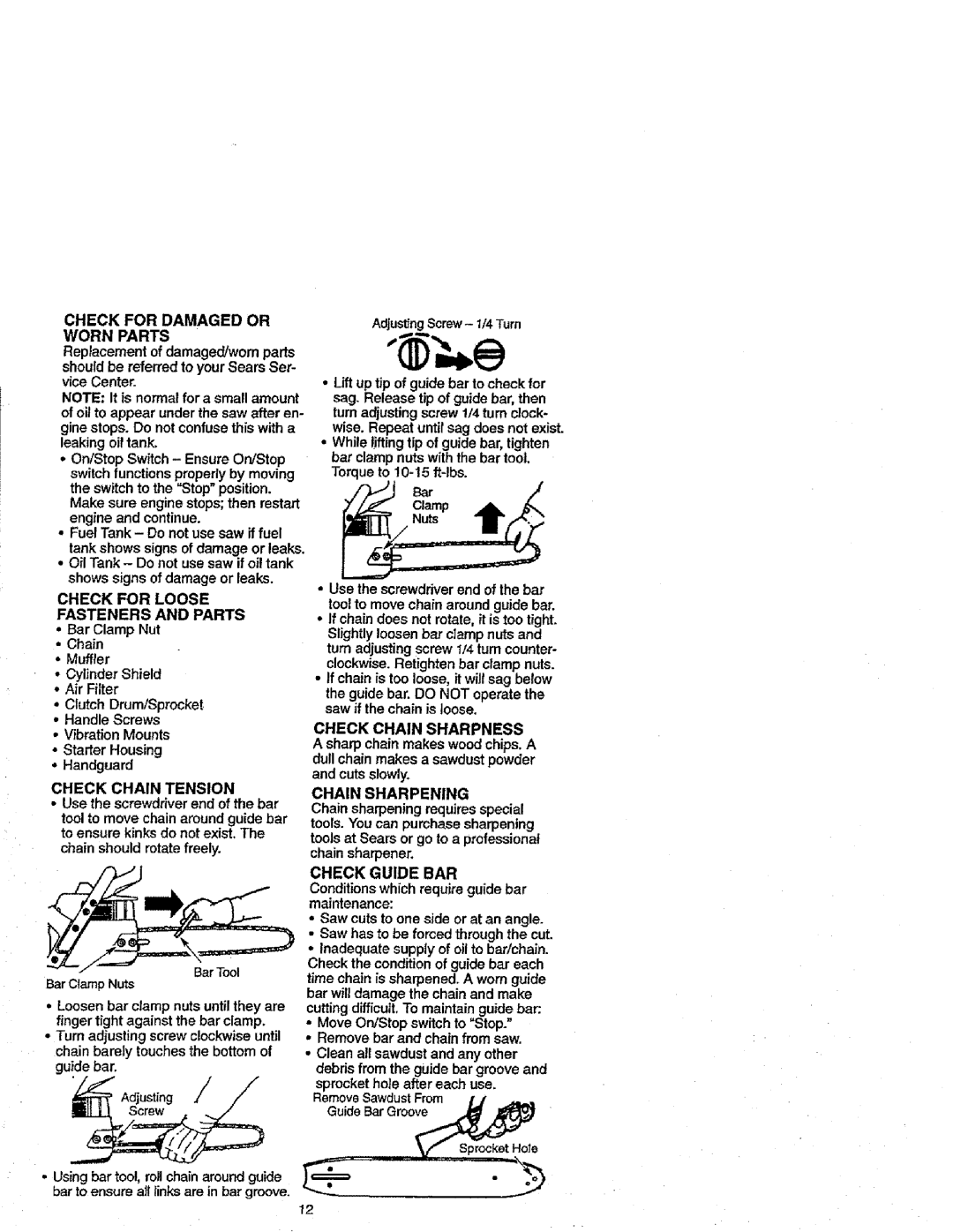

Adiu_ng Screw - 1/4 rum

•Lift up tip of guide bar to check for sag. Release tip of guide bar, then turn adjusting screw 1/4 turn clock- wise. Repeat until sag does not exist.

•While lifting tip of guide bar, tighten bar clamp nuts with the bar tool. Torque to

•Use the screwdriver end of the bar

CHECK FOR LOOSE

FASTENERS AND PARTS

°Bar Clamp Nut

• Chain

• Muffler

•Cylinder Shield

•Nr Filter

•Clutch Drum/Sprocket ° Handle Screws

•VibrationMounts

•Starter Housing

° Handguard

CHECK CHAIN TENSION

°Use the screwdriver end of the bar

tool to move chain around guide bar to ensure kinks do not exist. The chain should rotate freely.

Bar Tool

Bar Clamp Nuts

•Loosen bar clamp nuts until they are finger tight against the bar clamp.

•Turn adjusting screw clockwise until chain barely touches the bottom of guide bar.

Aiost,ogJ

°Using bar tool, roll chain around guide bar to ensure all links are in bar groove.

tool to move chain around guide bar.

°If chain does not rotate, it is too tight. Slightly loosen bar clamp nuts and turn adjusting screw 1/4 turn counter- clockwise. Retighten bar clamp nuts.

•If chain is too loose, it will sag below

the guide bar. DO NOT operate the saw if the chain is loose.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dull chain makes a sawdust powder and cuts slowly.

CHAIN SHARPENING

Chain sharpening requires special tools. You can purchase sharpening tools at Sears or go to a professional chain sharpener.

CHECK GUIDE BAR

Conditions which require guide bar maintenance:

•Saw cuts to one side or at an angle.

•Saw has to be forced through the cut.

•Inadequate supply of oil to bar/chaln.

Check the condition of guide bar each time chain is sharpened. A worn guide bar will damage the chain and make cutting difficult, To maintain guide bar:

•Move On/Stop switch to "Stop."

•Remove bar and chain from saw,

•Clean all sawdust and any other debris from the guide bar groove and

sprocket hole after each use. RemoveSawdust From

Guide BarGroo_,_

12