Diagnostics and Troubleshooting

Additional Troubleshooting Tips for the Processor

You can avoid many error conditions by following these guidelines:

•Check that the processor is turned ON and warmed up prior to printing.

•Follow the daily, weekly, monthly and periodic maintenance guidelines outlined in Chapter 4.

•When adding chemicals or water to the processor tanks, install a splash guard over the entrance area of the processor to prevent water and chemicals from entering the printer.

WARNING: When troubleshooting or performing maintenance procedures that require the main power to be turned off, turn off the main power for the processor on the OCP and at the circuit breaker to prevent:

•injury from moving parts and high voltage electricity

•losing the processor parameters

•Do not allow the emulsion side of the processed prints to touch each other until they are completely dry.

Calibration Troubleshooting

This section describes the problems that you may occasionally have when using the KODAK Device Calibration Software or the Calibration Software for the KODAK PROFESSIONAL LED II Printer. It also identifies the probable causes for these problems and provides solutions for correcting these problems.

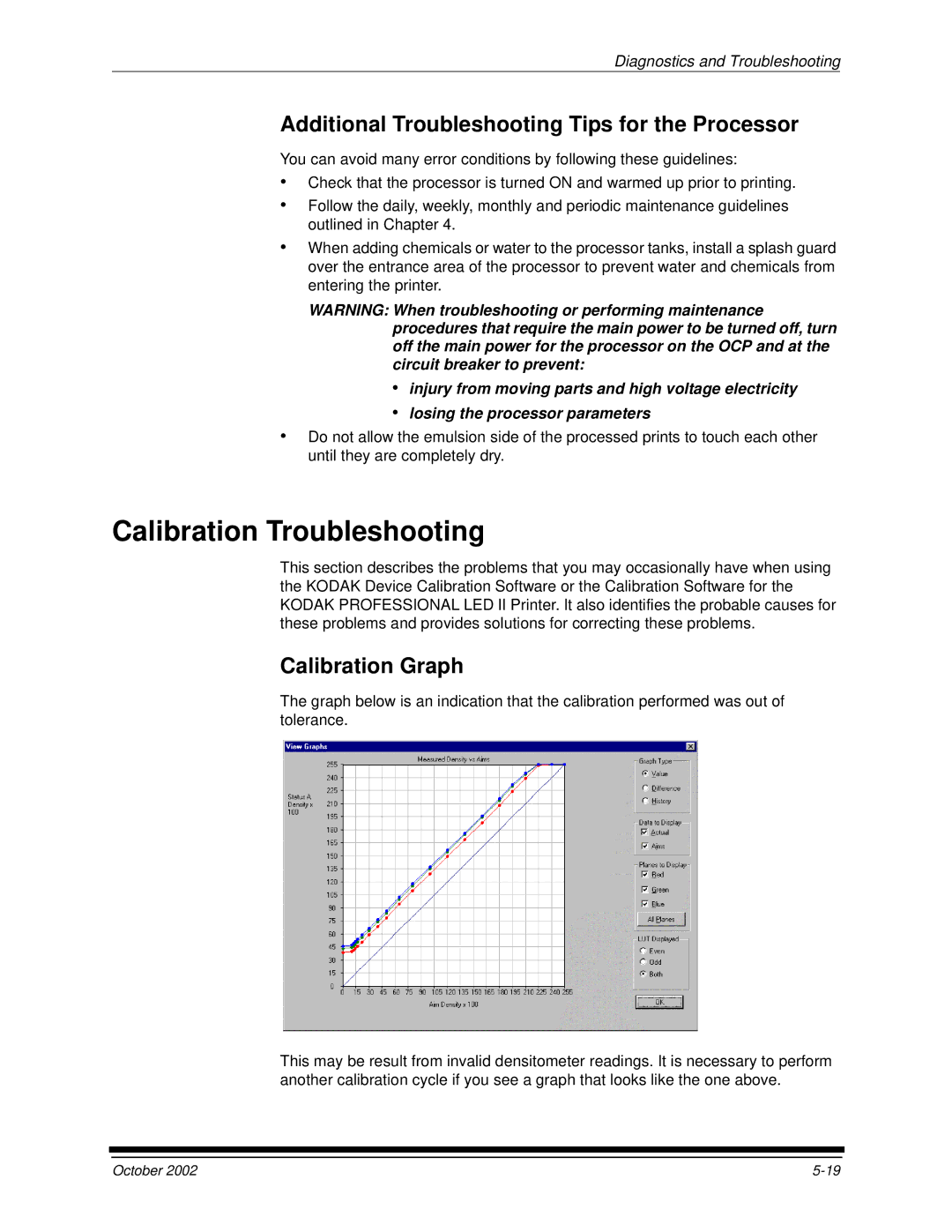

Calibration Graph

The graph below is an indication that the calibration performed was out of tolerance.

This may be result from invalid densitometer readings. It is necessary to perform another calibration cycle if you see a graph that looks like the one above.

October 2002 |