Filter

i_

Fuel

Fuel Line

CHECK MUFFLER MOUNTING SCREWS

Once each year, ensure muffler mounting screws are secure and tight- ened properly to prevent damage.

Mounting

Screw

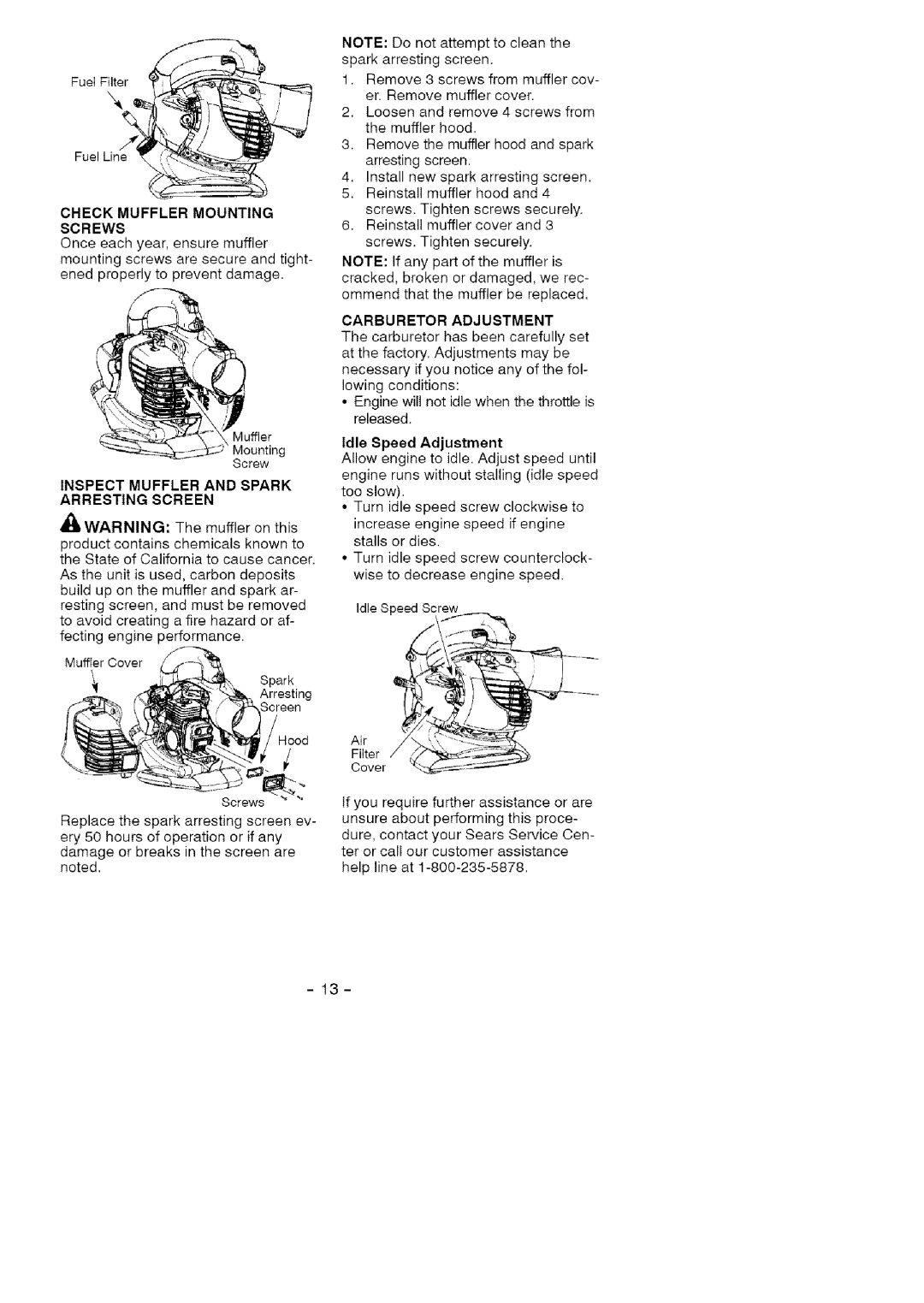

INSPECT MUFFLER AND SPARK ARRESTING SCREEN

_f_,WARNING: The muffler on this

product contains chemicals known to the State of California to cause cancer.

As the unit is used, carbon deposits build up on the muffler and spark ar- resting screen, and must be removed to avoid creating a fire hazard or af- fecting engine performance.

Muffler Cover

_ISpark Arresting

NOTE: Do not attempt to clean the spark arresting screen.

1.Remove 3 screws from muffler cov- er. Remove muffler cover.

2.Loosen and remove 4 screws from the muffler hood.

3.Remove the muffler hood and spark arresting screen.

4.Install new spark arresting screen.

5.Reinstall muffler hood and 4 screws. Tighten screws securely.

6.Reinstall muffler cover and 3 screws. Tighten securely.

NOTE: If any part of the muffler is cracked, broken or damaged, we rec- ommend that the muffler be replaced.

CARBURETOR ADJUSTMENT

The carburetor has been carefully set at the factory. Adjustments may be necessary if you notice any of the fol- lowing conditions:

•Engine will not idle when the throttle is released.

Idle Speed Adjustment

Allow engine to idle. Adjust speed until engine runs without stalling (idle speed too slow).

•Turn idle speed screw clockwise to increase engine speed if engine stalls or dies.

•Turn idle speed screw counterclock- wise to decrease engine speed.

Idle Speed Screw

co er

Screws " "

Replace the spark arresting screen ev- ery 50 hours of operation or if any

damage or breaks in the screen are noted.

If you require further assistance or are unsure about performing this proce- dure, contact your Sears Service Cen- ter or call our customer assistance help line at