TENANCE

i iii ill | ill llll |

NOTE: Any greasing or oiling of the above components can cause contamination of the friction wheet tf the disc

drive plate or friction wheel come in contact _th grease or oil, damage to the friction wheel will result.

Should grease or oil come in contact with the disc dd_e plate or friction wheel, be sure to clean the plate and wheel thoroughly.

NOTE! For storage, the hex shaft and gears should be wiped _with

®Auger Gear Box - The auger gear box has been factory lubricated for life. Iffor some reason lubricant Sl_ould leak out, have auger gear case checked by a co[npetent repairman

iiii | i | , iiiiiii i,illllllM,,II |

|

|

"_ | .__NOTE: | OIL LEVEL |

.,_,_To, L" ..,/._,V | MUST | BE B !_TWEEN |

.,,_"F._"."_7 |

| FULt '_,',q) |

AD[_ MARK

FIG. 21

OIL FILLCAP/

DIPSTICK

ENGINE

LUBRICATION

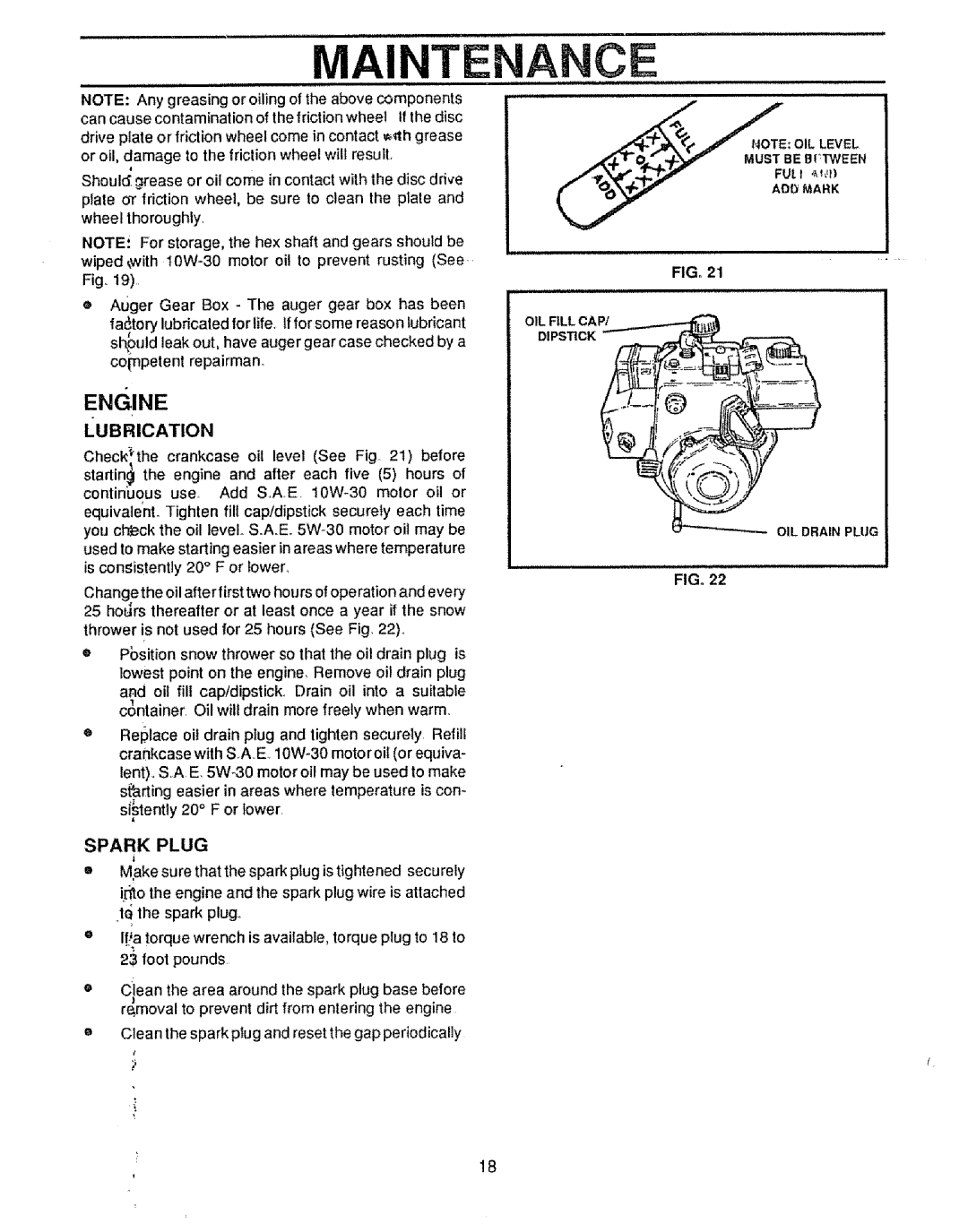

Check, the crankcase oil level (See Fig. 21) before

startin_l the engine and after each five (5) hours of contin'uous use. Add SAE

equivale'ntoTighten fill cap/dipstick securely each time

you ch_ck the oil level° S.A.E.

is consistently 20 ° F or lower..

FtGo 22

Change the oil after first two hours of operation and every 25 hot_rs thereafter or at least once a year if the snow thrower is not used for 25 hours (See Fig. 22).

®Pbsition snow thrower so that the oil drain plug is lowest point on the engine, Remove oil drain plug

and oil fill cap/dipstick Drain oil into a suitable

"t ,

container. Oil will drain more freely when warm.

oReptace oil drain plug and tighten securely Refill crankcase with SAE.

SPARK PLUG

•Make sure that the spark ptug is tightened secu rely

i_o the engine and the spark plug wire is attached

.re the spark plug..

elPa torque wrench is available, torque plug to 18 to

*'h

23 foot pounds

eClean the area around the spark plug base before

J | . | , |

r_moval to prevent d_rtfrom entering the engine

eClean the spark plug and reset the gap periodically

t

18