For the most pmeasurefrom your Scrol! Saw/ Sander follow these instructions carefully:

The Craftsman Scroll Saw is a

FORWARD | TO |

| (A) |

|

|

TIGHTEN | BLADE | _ |

|

|

|

SAW | ARM | ,.._.tt | _ | T SPRING | .... |

|

|

| ...... |

|

engrave and perform many other hobby, home or shop operations Use with 2471 accessory pack.

DO NOT OPERATE MACHINE WITHOUT ATTACHING TABLE, CAUTION: DISCONNECT PLUG FROM OUTLET,,

inserting

_\\

[

WING NUT _

WASHER

LOCATED

//_..SAW LIFT BLADE GUARD

...........................................................FRLOMTHlS POStT ON

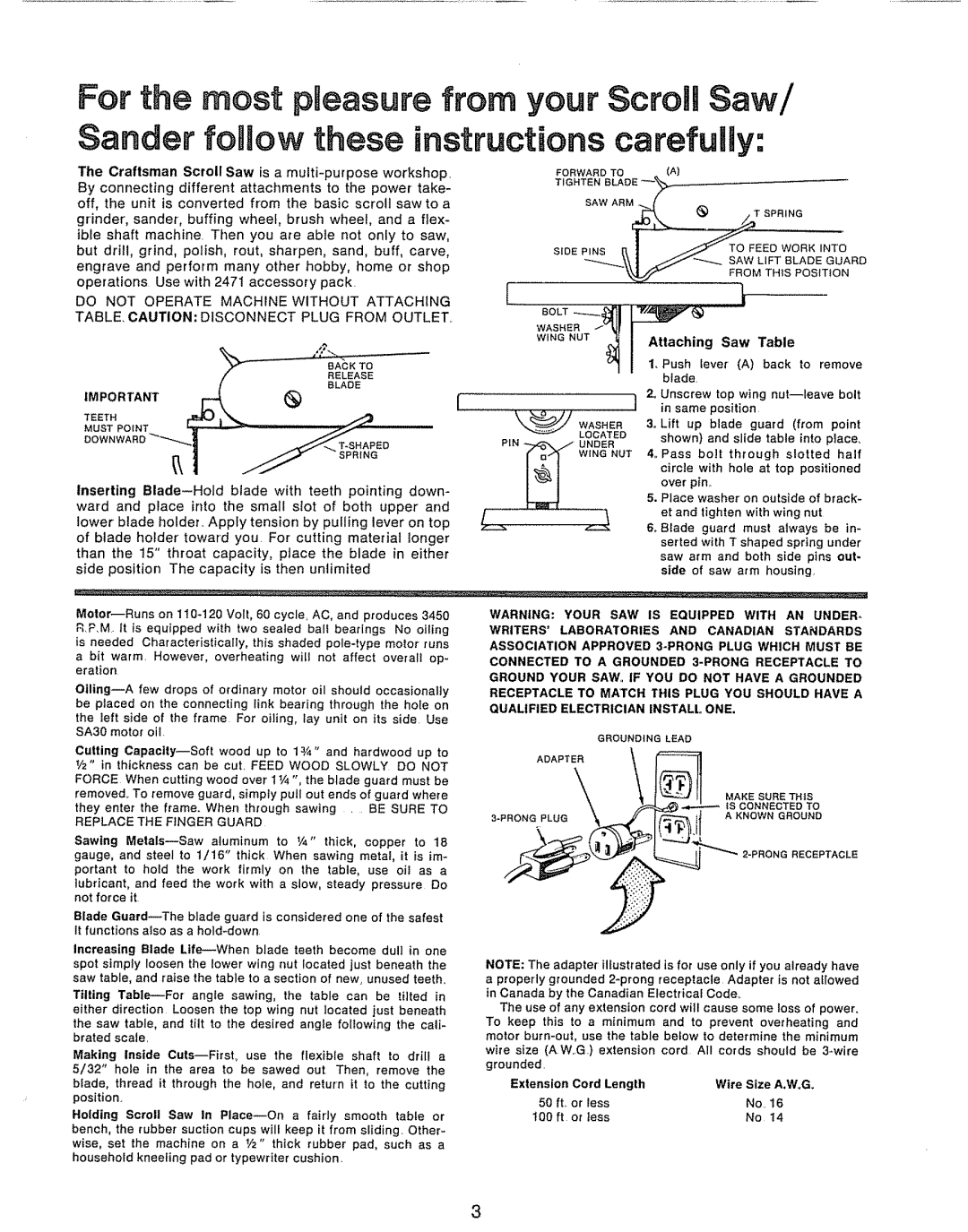

I Attaching Saw Table

I 1. Push lever (A) back to remove blade.

] 2, Unscrew top wing

3.Lift up blade guard (from point shown) and slide table into place,

4,, Pass bolt through slotted half circle with hole at top positioned over pin..

5.Place washer on outside of brack- et and tighten with wing nut

of blade holder toward you. For cutting material longer than the 15" throat capacity, place the blade in either side position The capacity is then unlimited

is needed Characteristically, this shaded poleqype motor runs

a bit warm. However, overheating wilt not affect overall op- eration

Oiling_A few drops of ordinary motor oil should occasionally be placed on the connecting link bearing through the hole on the _eft side of the frame For oiling, tay unit on its side. Use SA30 motor oil

&Blade guard must always be in- serted with T shaped spring under

saw arm and both side pins out- side of saw arm housing,

WARNING: YOUR SAW IS EQUIPPED WITH AN UNDER-

WRITERS' LABORATORIES AND CANADIAN STANDARDS ASSOCIATION APPROVED

RECEPTACLE TO MATCH THIS PLUG YOU SHOULD HAVE A QUALIFIED ELECTRICIAN INSTALL ONE.

GROUNDING LEAD

Cutting Capacity_Soft wood up to 1%" and hardwood up to _/2" in thickness can be cut. FEED WOOD SLOWLY DO NOT FORCE When cutting wood over 1 V4", the blade guard must be

removed,. To remove guard, simply putl out ends of guard where they enter the frame. When through sawing .... BE SURE TO

REPLACE THE FINGER GUARD

Sawing Metals_Saw aluminum to V4" thick, copper to 18 gauge, and steel to 1/16" thick When sawing metal, it is im- portant to hold the work firmly on the table, use oil as a lubricant, and feed the work with a stow, steady pressure Do not force it.

Blade Guard_The blade guard is considered one of the safest It functions also as a

Increasing Blade

spot simpty loosen the lower wing nut located just beneath the saw table, and raise the table to a section of new, unused teeth..

Tilting

Making Inside

blade, thread it through the hole, and return it to the cutting position.

Holding Scroll Saw In Place_On a fairly smooth table or bench, the rubber suction cups will keep it from sliding. Other-

wise, set the machine on a _/2" thick rubber pad, such as a household kneefing pad or typewriter cushion.

ADAPTER |

|

|

| MAKE SURE TH_S | |

| tS CONNECTED | TO |

A KNOWN GROUND | ||

|

| |

| RECEPTACLE | |

NOTE: The adapter illustrated is for use only if you already have a properly grounded

The use of any extension cord wilF cause some loss of power. To keep this to a minimum and to prevent overheating and motor

wire size | (AW..G.} extension cord All cords should be | |||||

grounded. |

|

|

|

|

|

|

Extension | Cord Length | Wire Size | A.W,G_ | |||

| 50 | ftr= | or | Iess | No. | 16 |

t00 | ft | or | tess | No | 14 | |

3