CLEANING THE FLAIL SCREEN

If the discharge area becomes clogged, remove the flail screen and clean area as follows.

•Stop engine, make certain the

•Remove the two hand knobs on each side of the discharge chute. Lift the discharge chute up, and keep it out of the way.

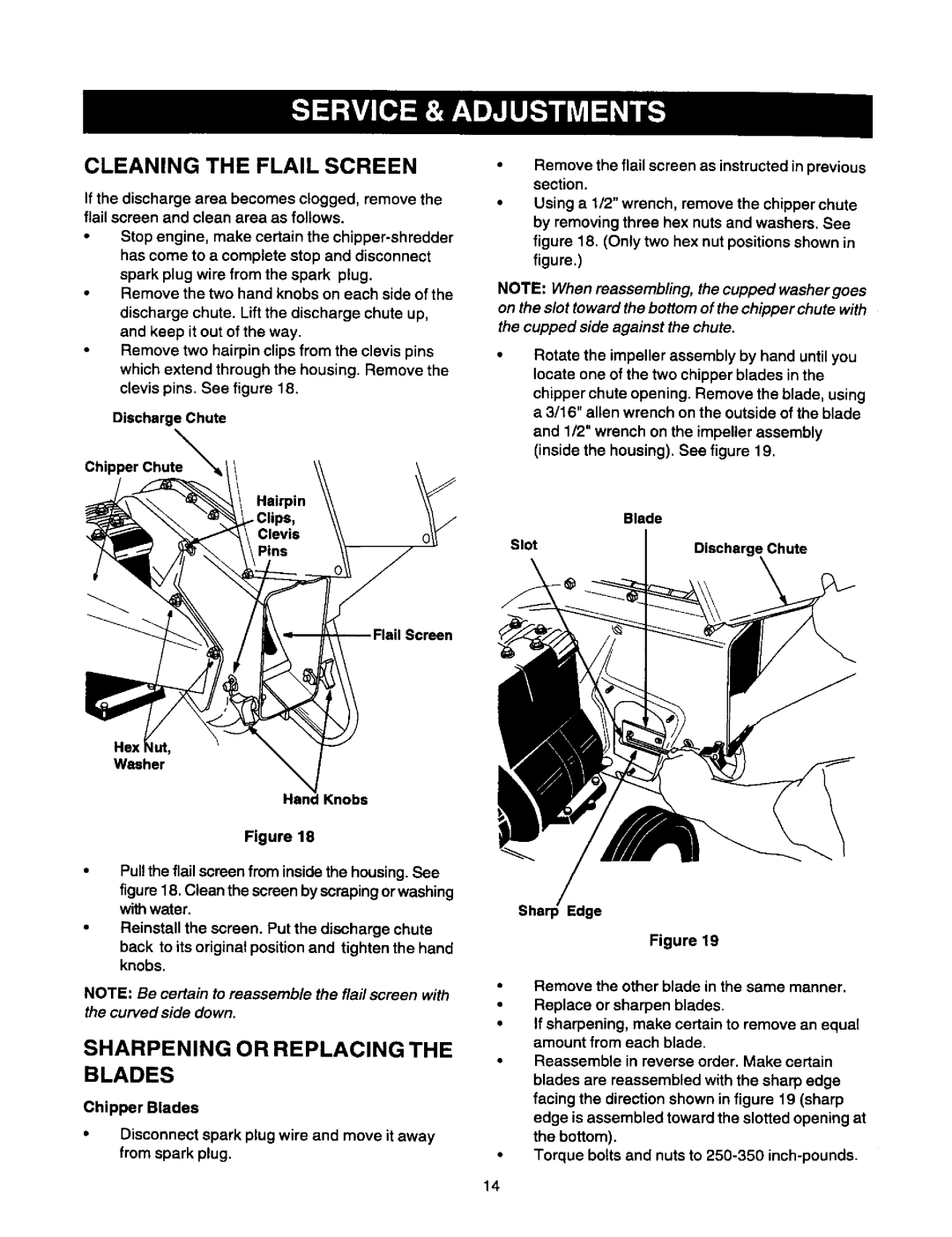

•Remove two hairpin clips from the clevis pins which extend through the housing. Remove the clevis pins. See figure 18.

Discharge Chute

Chipper Chute_'

Hairpin

Clips,

Clevis

Pins

Screen

Hexl=ut,

Washer

Knobs

Figure 18

•Pul!the flail screen from inside the housing. See

figure 18. Clean the screen by scraping or washing with water.

•Reinstall the screen. Put the discharge chute back to its original position and tighten the hand knobs.

NOTE: Be certain to reassemble the flail screen with the curved side down.

SHARPENING OR REPLACING THE BLADES

Chipper Blades

•Disconnect spark plug wire and move it away from spark plug.

Remove the flail screen as instructed in previous section.

Using a 1/2" wrench, remove the chipper chute by removing three hex nuts and washers. See figure 18. (Only two hex nut positions shown in

figure.)

NOTE: When reassembling, the cupped washer goes on the slot toward the bottom of the chipper chute with the cupped side against the chute.

Rotate the impeller assembly by hand until you locate one of the two chipper blades in the

chipper chute opening. Remove the blade, using a 3/16" allen wrench on the outside of the blade

and 1/2" wrench on the impeller assembly (inside the housing). See figure 19.

Blade

Slot | Discharge Chute |

|

Figure 19

Remove the other blade in the same manner. Replace or sharpen blades.

If sharpening, make certain to remove an equal amount from each blade.

Reassemble in reverse order. Make certain blades are reassembled with the sharp edge facing the direction shown in figure 19 (sharp edge is assembled toward the slotted opening at the bottom).

Torque bolts and nuts to

14