The carburetor may need

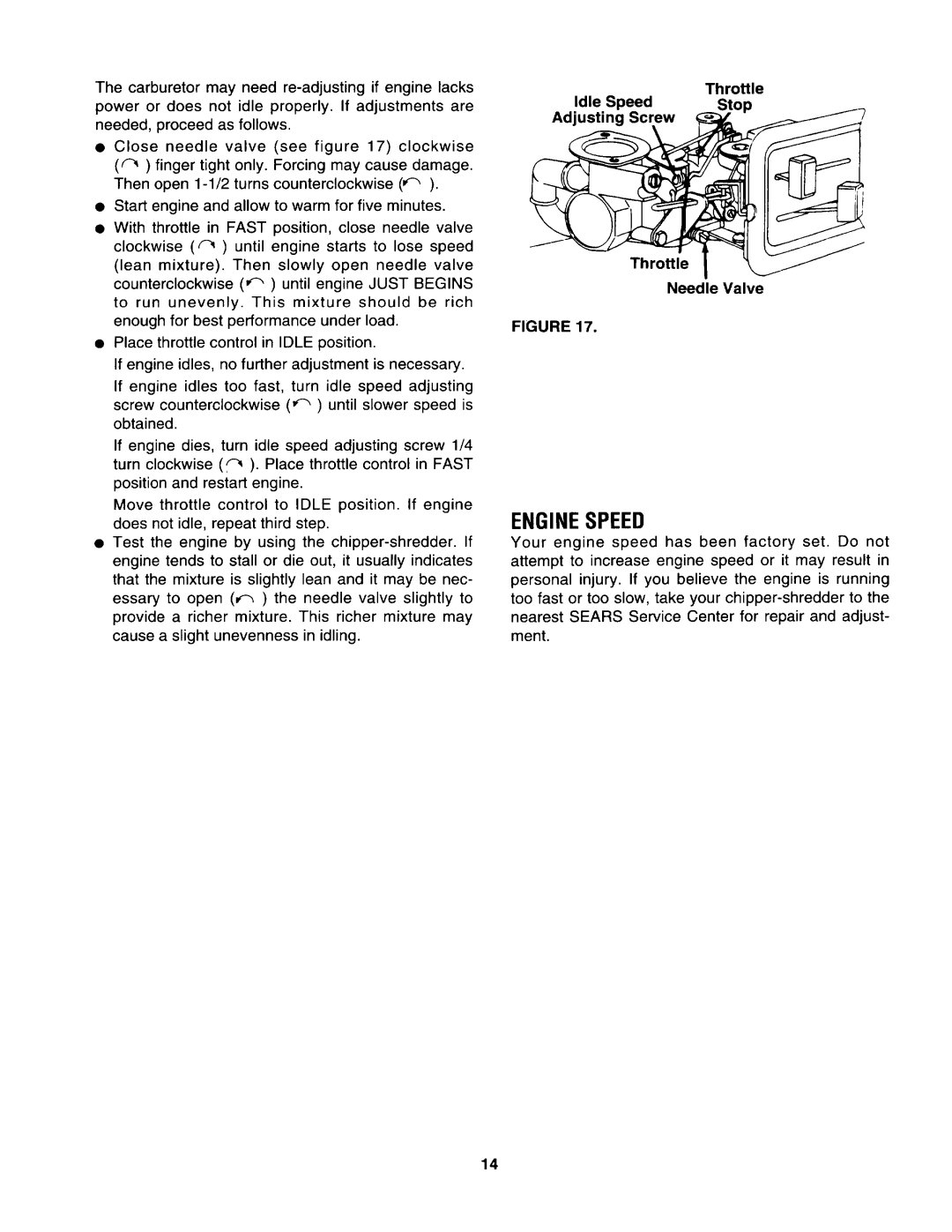

•Close needle valve (see figure 17) clockwise (F_) finger tight only. Forcing may cause damage. Then open

•Start engine and allow to warm for five minutes.

•With throttle in FAST position, close needle valve

clockwise (_) until engine starts to lose speed (lean mixture). Then slowly open needle valve counterclockwise

•Place throttle control in IDLE position.

If engine idles, no further adjustment is necessary. If engine idles too fast, turn idle speed adjusting

screw counterclockwise (_'_) until slower speed is obtained.

If engine dies, turn idle speed adjusting screw 1/4 turn clockwise

Move throttle control to IDLE position. If engine does not idle, repeat third step.

•Test the engine by using the

Throttle

Idle Speed

ustin_

Throttle

Needle Valve

FIGURE 17.

ENGINESPEED

Your engine speed has been factory set. Do not attempt to increase engine speed or it may result in personal injury. If you believe the engine is running too fast or too slow, take your

14