917.276920 specifications

The Craftsman 917.276920 is a versatile and reliable lawn tractor designed to tackle a range of outdoor tasks while delivering exceptional performance. This machine is equipped with advanced features and technologies that make lawn care easier and more efficient for homeowners.One of the key characteristics of the Craftsman 917.276920 is its powerful engine. It typically comes with a robust 24 horsepower Kohler engine that provides ample power for cutting even the thickest grass. The engine is designed for reliability and durability, ensuring that users can depend on it for multiple seasons of heavy use.

The cutting deck is another standout feature of the Craftsman 917.276920. With a 54-inch cutting width, it allows for fast mowing over large areas. The deck height is adjustable, providing users with the flexibility to achieve the perfect lawn height, whether they prefer a short, manicured look or a longer, more natural appearance. The mower also features a dual-blade system that further enhances cutting performance, ensuring a clean and even finish.

In terms of user comfort, the Craftsman 917.276920 is designed with ergonomics in mind. It comes with an adjustable high-back seat that provides support during long mowing sessions. The steering system is also user-friendly, featuring a smooth and responsive maneuverability that makes navigating tight spaces and obstacles easy. Additionally, the tractor's controls are intuitively placed for straightforward operation, reducing the learning curve for new users.

Another important feature of this lawn tractor is its versatility. The Craftsman 917.276920 is compatible with various attachments, including baggers, mulchers, and even snow blowers, allowing it to handle multiple tasks throughout the year. This adaptability makes it a valuable tool for homeowners looking to maintain their yards across seasons.

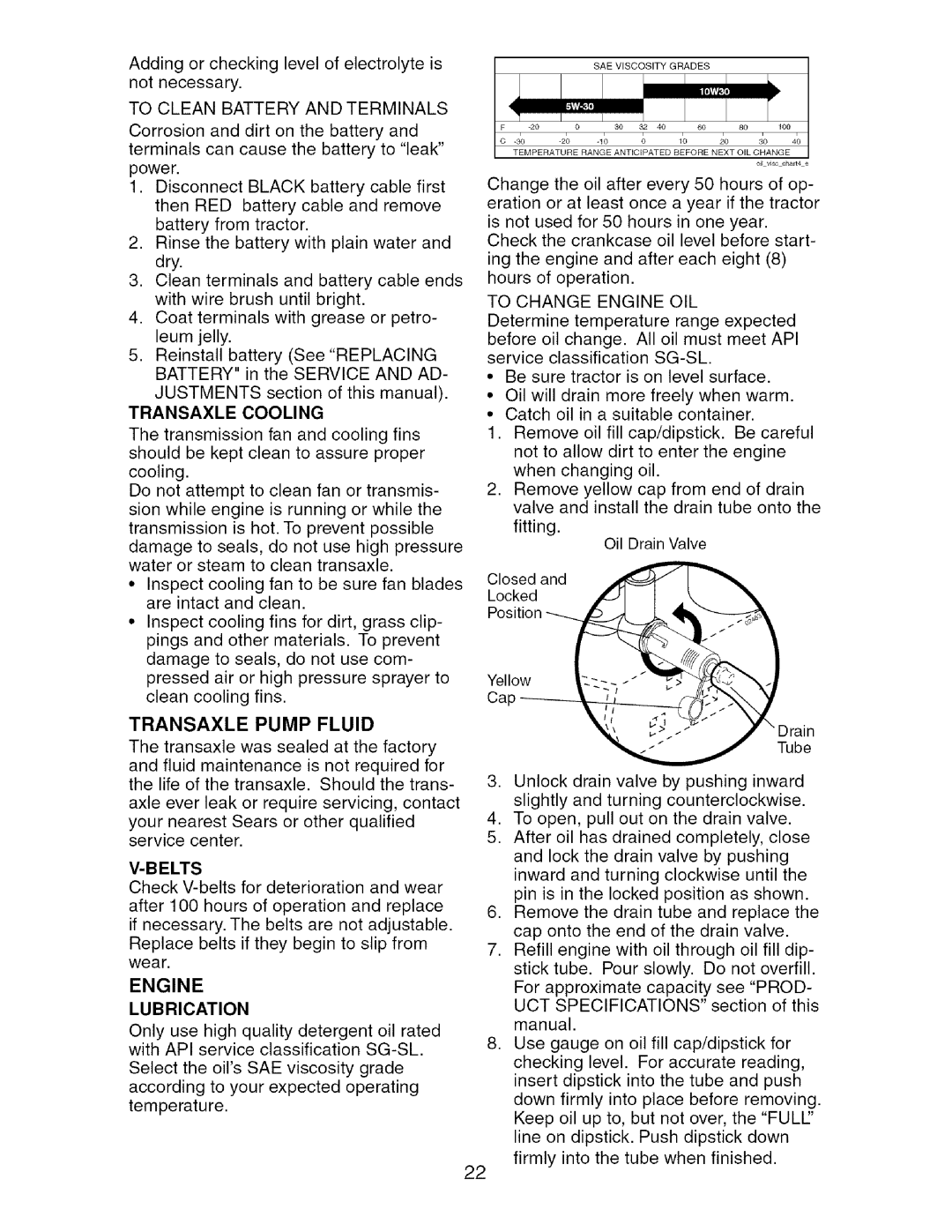

For those concerned about maintenance, the Craftsman 917.276920 includes features designed for easy upkeep. The engine is equipped with an easy-access oil fill and filter, simplifying routine maintenance. The cutting deck can also be easily removed for cleaning and servicing, ensuring that the mower stays in peak condition.

Overall, the Craftsman 917.276920 lawn tractor combines power, comfort, and versatility, making it an excellent choice for homeowners seeking a reliable solution for their lawn care needs. Its advanced features and technologies contribute to a practical and enjoyable mowing experience, allowing users to achieve professional-looking results in their own backyard.