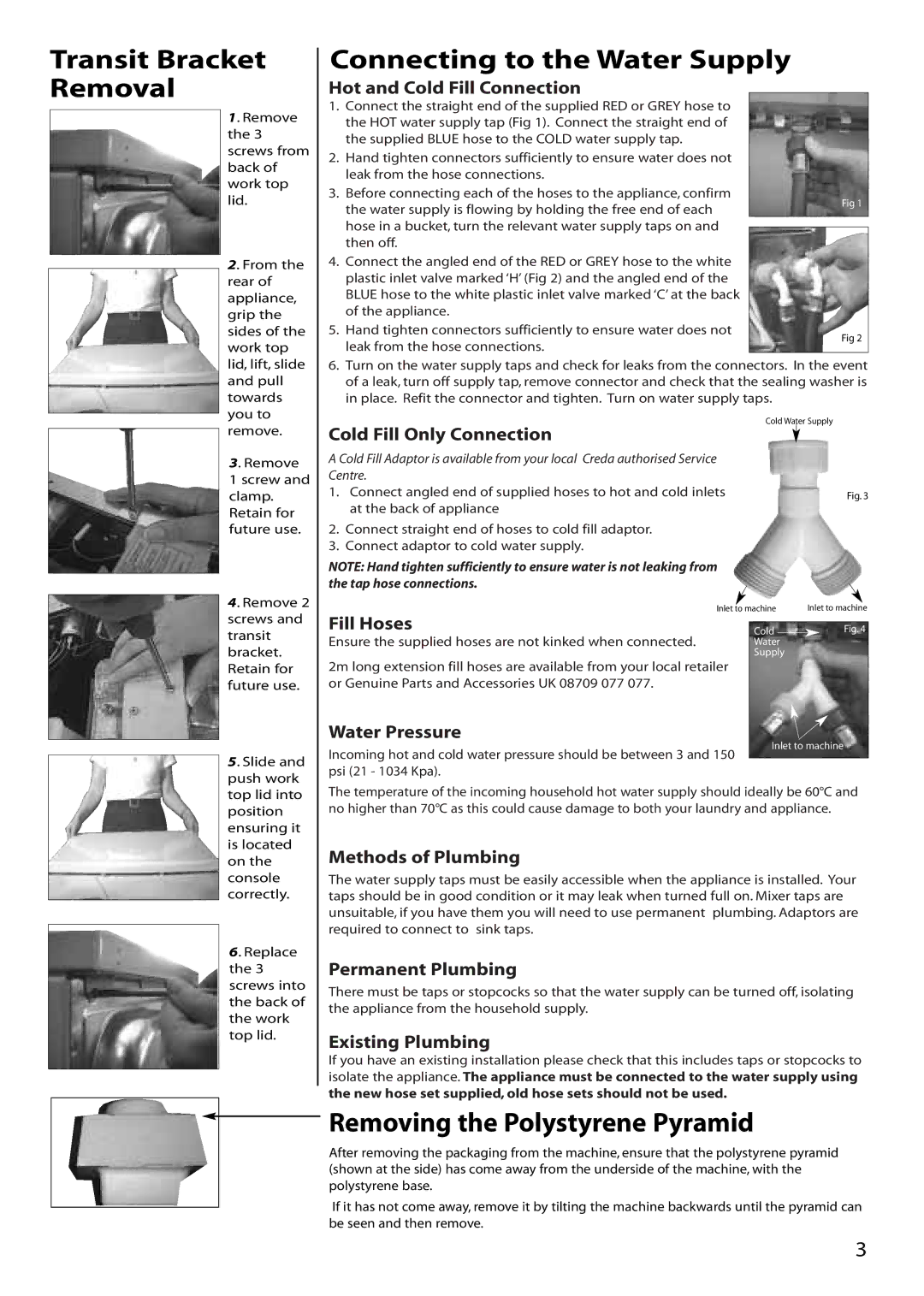

Transit Bracket Removal

1. Remove the 3 screws from back of work top

Connecting to the Water Supply

Hot and Cold Fill Connection

1.Connect the straight end of the supplied RED or GREY hose to the HOT water supply tap (Fig 1). Connect the straight end of the supplied BLUE hose to the COLD water supply tap.

2.Hand tighten connectors sufficiently to ensure water does not leak from the hose connections.

3.Before connecting each of the hoses to the appliance, confirm

lid.

the water supply is flowing by holding the free end of each hose in a bucket, turn the relevant water supply taps on and then off.

Fig 1

2. From the rear of appliance, grip the sides of the

4. Connect the angled end of the RED or GREY hose to the white plastic inlet valve marked ‘H’ (Fig 2) and the angled end of the BLUE hose to the white plastic inlet valve marked ‘C’ at the back of the appliance.

5. Hand tighten connectors sufficiently to ensure water does not

work top

leak from the hose connections.

Fig 2

lid, lift, slide and pull towards you to

6.Turn on the water supply taps and check for leaks from the connectors. In the event of a leak, turn off supply tap, remove connector and check that the sealing washer is in place. Refit the connector and tighten. Turn on water supply taps.

remove.

3. Remove

1 screw and clamp. Retain for future use.

Cold Fill Only Connection

A Cold Fill Adaptor is available from your local Creda authorised Service Centre.

1.Connect angled end of supplied hoses to hot and cold inlets at the back of appliance

2.Connect straight end of hoses to cold fill adaptor.

3.Connect adaptor to cold water supply.

NOTE: Hand tighten sufficiently to ensure water is not leaking from the tap hose connections.

Cold Water Supply

Fig. 3

4. Remove 2

Inlet to machine | Inlet to machine |

screws and transit bracket. Retain for future use.

5. Slide and push work

Fill Hoses

Ensure the supplied hoses are not kinked when connected.

2m long extension fill hoses are available from your local retailer or Genuine Parts and Accessories UK 08709 077 077.

Water Pressure

Incoming hot and cold water pressure should be between 3 and 150 psi (21 - 1034 Kpa).

Cold | Fig. 4 |

Water |

|

Supply |

|

Inlet to machine

top lid into position ensuring it is located on the console correctly.

6. Replace the 3 screws into the back of the work top lid.

The temperature of the incoming household hot water supply should ideally be 60°C and no higher than 70°C as this could cause damage to both your laundry and appliance.

Methods of Plumbing

The water supply taps must be easily accessible when the appliance is installed. Your taps should be in good condition or it may leak when turned full on. Mixer taps are unsuitable, if you have them you will need to use permanent plumbing. Adaptors are required to connect to sink taps.

Permanent Plumbing

There must be taps or stopcocks so that the water supply can be turned off, isolating the appliance from the household supply.

Existing Plumbing

If you have an existing installation please check that this includes taps or stopcocks to isolate the appliance. The appliance must be connected to the water supply using

the new hose set supplied, old hose sets should not be used.

Removing the Polystyrene Pyramid

Removing the Polystyrene Pyramid

After removing the packaging from the machine, ensure that the polystyrene pyramid (shown at the side) has come away from the underside of the machine, with the polystyrene base.

If it has not come away, remove it by tilting the machine backwards until the pyramid can be seen and then remove.

3