IX Fuel Line Piping

Fuel line piping design, materials and constructions must be in accordance with local building codes, requirements of the local authority having jurisdiction, and the latest edition of Installation of Oil-Burning Equipment (ANSI/NFPA 31). Refer also to the instruction manuals provided with the burner and oil pump.

Depending on the location of the fuel oil storage tank in relation to the oil burner, there are four types of oil piping systems generally being used:

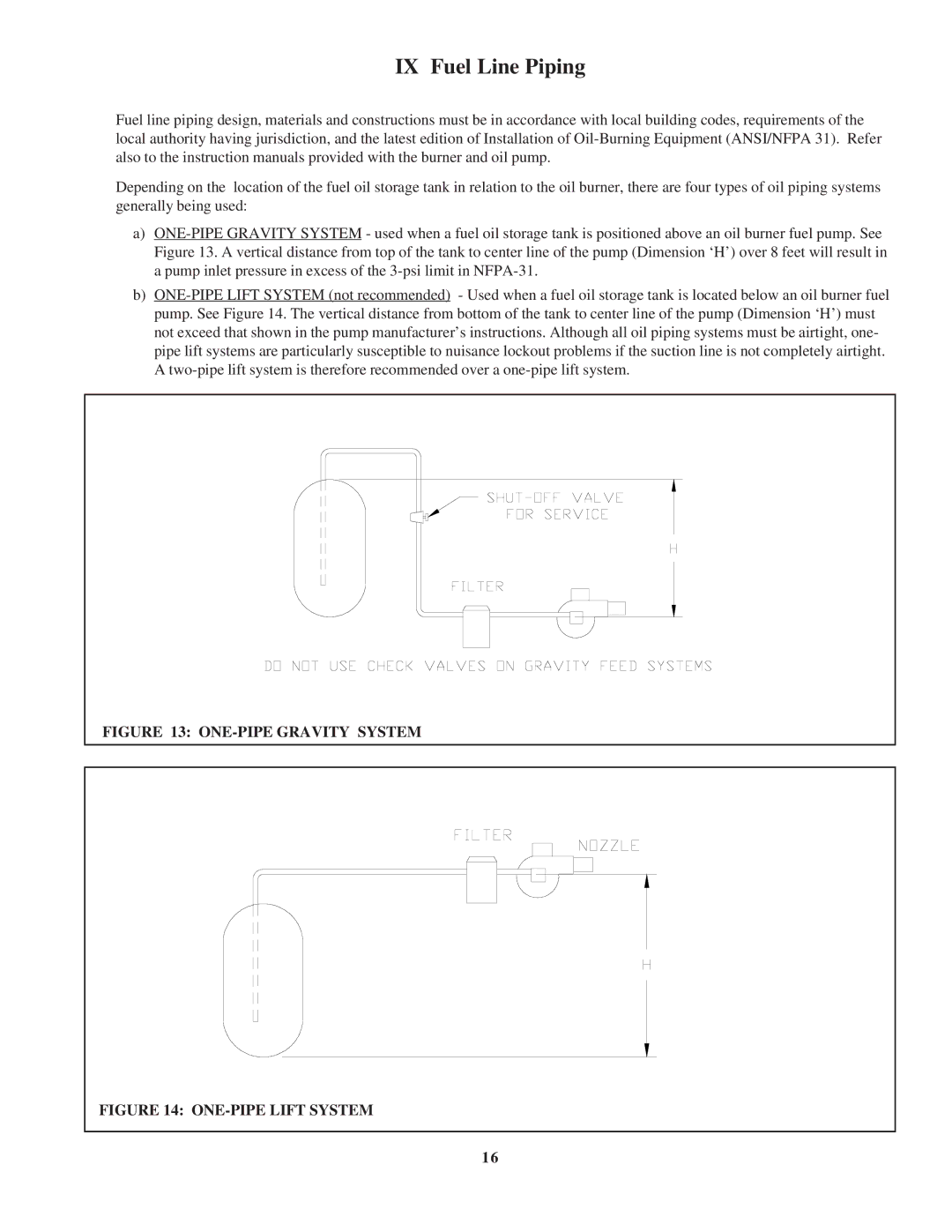

a)ONE-PIPE GRAVITY SYSTEM - used when a fuel oil storage tank is positioned above an oil burner fuel pump. See Figure 13. A vertical distance from top of the tank to center line of the pump (Dimension ‘H’) over 8 feet will result in a pump inlet pressure in excess of the 3-psi limit in NFPA-31.

b)ONE-PIPE LIFT SYSTEM (not recommended) - Used when a fuel oil storage tank is located below an oil burner fuel pump. See Figure 14. The vertical distance from bottom of the tank to center line of the pump (Dimension ‘H’) must not exceed that shown in the pump manufacturer’s instructions. Although all oil piping systems must be airtight, one- pipe lift systems are particularly susceptible to nuisance lockout problems if the suction line is not completely airtight. A two-pipe lift system is therefore recommended over a one-pipe lift system.

FIGURE 13: ONE-PIPE GRAVITY SYSTEM

FIGURE 14: ONE-PIPE LIFT SYSTEM

1716