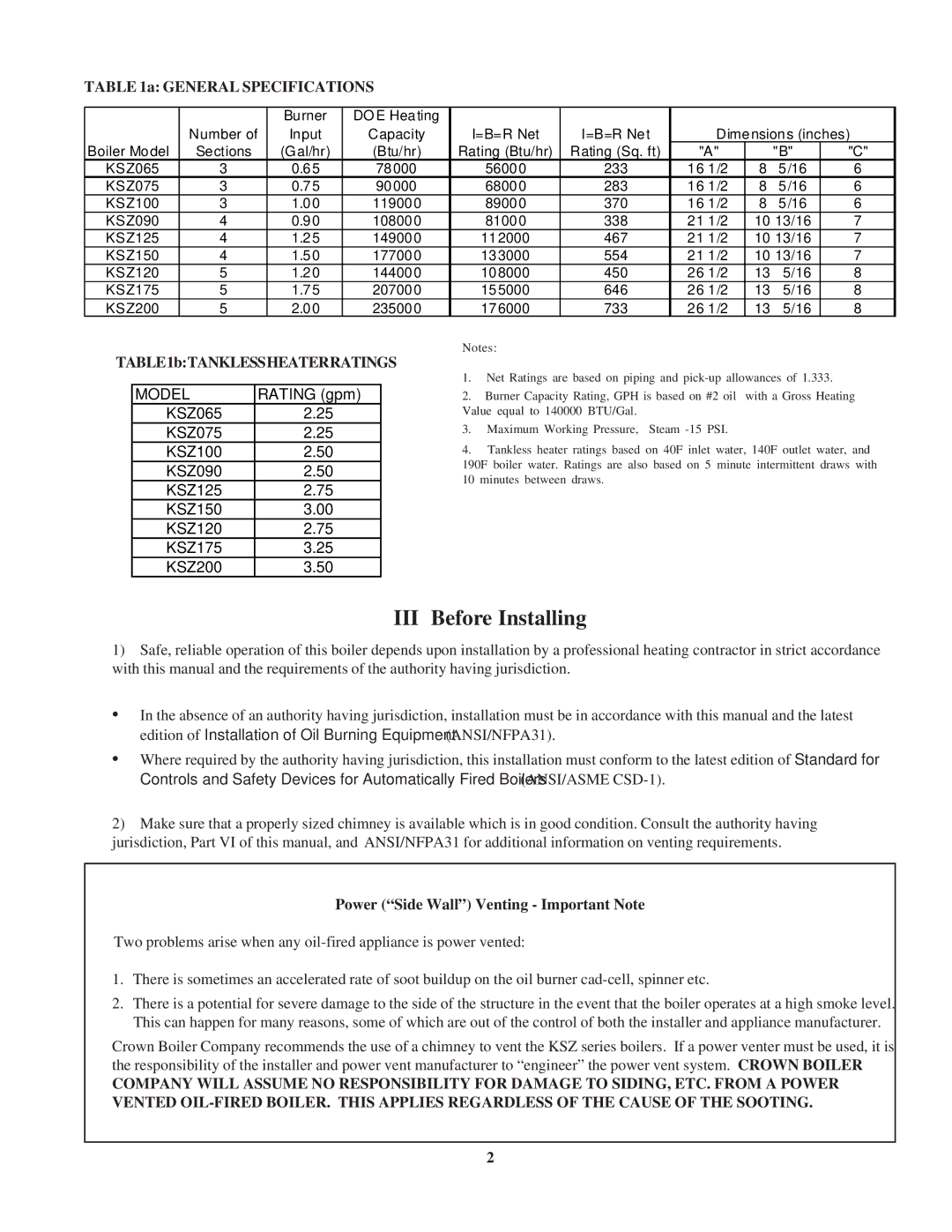

TABLE 1a: GENERAL SPECIFICATIONS

|

| Burner | DOE Heating |

|

|

|

|

|

|

| Number of | Input | Capacity | I=B=R Net | I=B=R Net | Dimensions (inches) | |||

Boiler Model | Sections | (Gal/hr) | (Btu/hr) | Rating (Btu/hr) | Rating (Sq. ft) | "A" |

| "B" | "C" |

KSZ065 | 3 | 0.65 | 78000 | 56000 | 233 | 16 1/2 | 8 | 5/16 | 6 |

KSZ075 | 3 | 0.75 | 90000 | 68000 | 283 | 16 1/2 | 8 | 5/16 | 6 |

KSZ100 | 3 | 1.00 | 119000 | 89000 | 370 | 16 1/2 | 8 | 5/16 | 6 |

KSZ090 | 4 | 0.90 | 108000 | 81000 | 338 | 21 1/2 | 10 13/16 | 7 | |

KSZ125 | 4 | 1.25 | 149000 | 112000 | 467 | 21 1/2 | 10 13/16 | 7 | |

KSZ150 | 4 | 1.50 | 177000 | 133000 | 554 | 21 1/2 | 10 13/16 | 7 | |

KSZ120 | 5 | 1.20 | 144000 | 108000 | 450 | 26 1/2 | 13 | 5/16 | 8 |

KSZ175 | 5 | 1.75 | 207000 | 155000 | 646 | 26 1/2 | 13 | 5/16 | 8 |

KSZ200 | 5 | 2.00 | 235000 | 176000 | 733 | 26 1/2 | 13 | 5/16 | 8 |

TABLE1b:TANKLESSHEATERRATINGS

MODEL | RATING (gpm) |

KSZ065 | 2.25 |

KSZ075 | 2.25 |

KSZ100 | 2.50 |

KSZ090 | 2.50 |

KSZ125 | 2.75 |

KSZ150 | 3.00 |

KSZ120 | 2.75 |

KSZ175 | 3.25 |

KSZ200 | 3.50 |

Notes:

1.Net Ratings are based on piping and

2.Burner Capacity Rating, GPH is based on #2 oil with a Gross Heating Value equal to 140000 BTU/Gal.

3.Maximum Working Pressure, Steam

4.Tankless heater ratings based on 40F inlet water, 140F outlet water, and 190F boiler water. Ratings are also based on 5 minute intermittent draws with

10minutes between draws.

IIIBefore Installing

1)Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in strict accordance with this manual and the requirements of the authority having jurisdiction.

•In the absence of an authority having jurisdiction, installation must be in accordance with this manual and the latest edition of Installation of Oil Burning Equipment (ANSI/NFPA31).

•Where required by the authority having jurisdiction, this installation must conform to the latest edition of Standard for Controls and Safety Devices for Automatically Fired Boilers (ANSI/ASME

2)Make sure that a properly sized chimney is available which is in good condition. Consult the authority having jurisdiction, Part VI of this manual, and ANSI/NFPA31 for additional information on venting requirements.

Power (“Side Wall”) Venting - Important Note

Two problems arise when any

1.There is sometimes an accelerated rate of soot buildup on the oil burner

2.There is a potential for severe damage to the side of the structure in the event that the boiler operates at a high smoke level. This can happen for many reasons, some of which are out of the control of both the installer and appliance manufacturer.

Crown Boiler Company recommends the use of a chimney to vent the KSZ series boilers. If a power venter must be used, it is the responsibility of the installer and power vent manufacturer to “engineer” the power vent system. CROWN BOILER

COMPANY WILL ASSUME NO RESPONSIBILITY FOR DAMAGE TO SIDING, ETC. FROM A POWER VENTED

32