MWC116ENL, MWC116ELL, MWC116ELT, MWC116ENT, MWC Series specifications

Crown Boiler's MWC Series represents a commendable choice in the realm of residential and light commercial heating solutions. Specifically, models like the MWC116ENT, MWC116ELT, MWC116ELL, and MWC116ENL stand out due to their exceptional performance, reliability, and innovative features.At the core of the MWC Series lies a robust cast iron boiler construction designed to withstand the test of time. This material not only provides durability but also enhances heat retention, thereby increasing the system's efficiency. Each model in this series is designed for natural gas or propane fuel types, ensuring flexibility based on availability and user preference.

A notable feature of the MWC116 models is the efficient heat exchanger, which enables rapid heating of water for both space heating and domestic hot water applications. With a heating capacity of 116,000 BTUs, these boilers deliver ample warmth for mid-sized homes or light commercial settings, making them a versatile option for various applications.

The MWC116ENT model is equipped with an energy-efficient electronic ignition system, which enhances reliability and efficiency. This technology reduces energy consumption, providing users with cost savings on their utility bills. Similarly, the MWC116ELT model boasts an integrated aquastat that regulates water temperature, ensuring optimal performance and comfort.

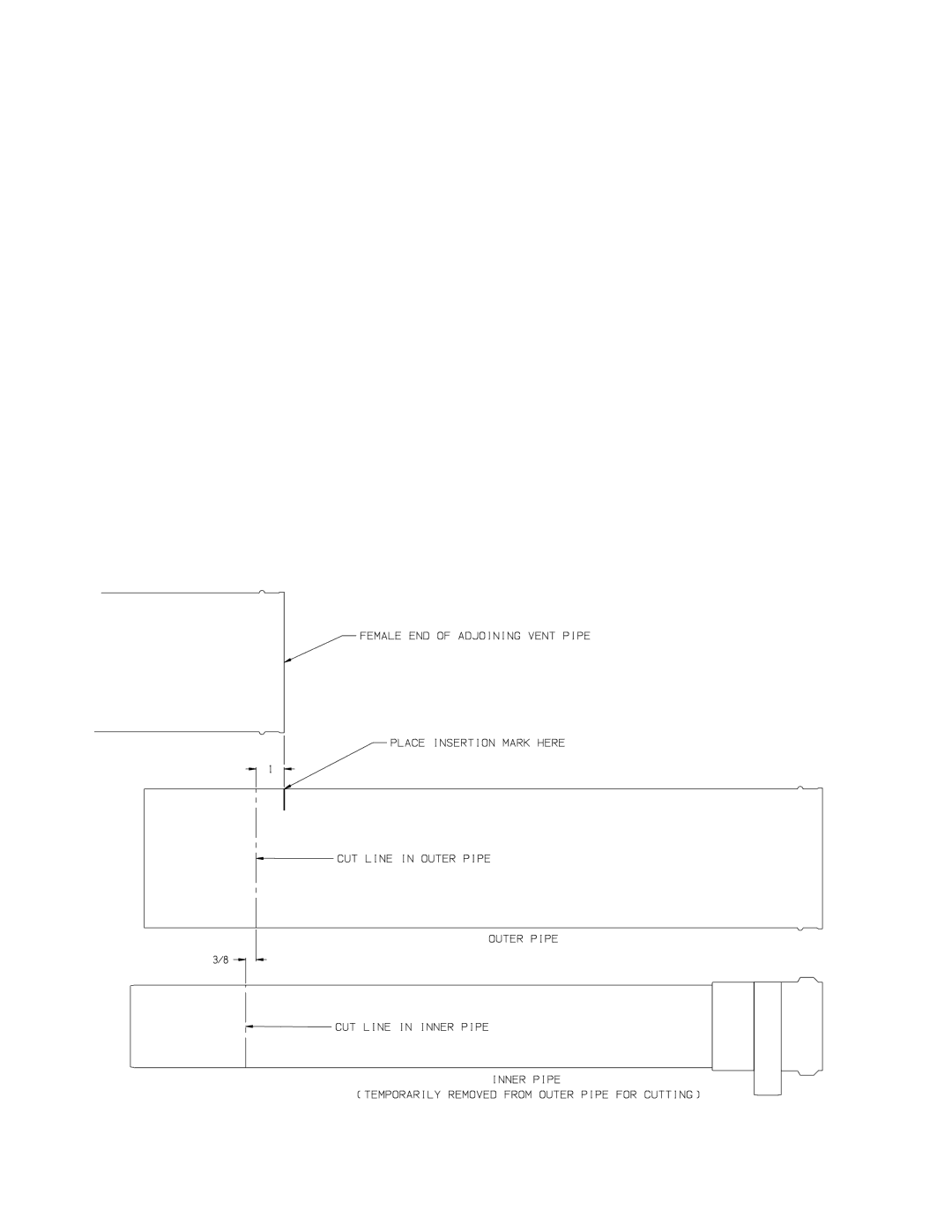

For those requiring increased venting options, the MWC116ELL model includes advanced horizontal venting capabilities, allowing for flexible installation in various environments. This feature aids in overcoming space limitations and facilitating optimal combustion conditions. The MWC116ENL, on the other hand, features a low NOx emissions configuration, making it an environmentally conscious choice for users concerned about their carbon footprint.

User-friendly controls are a characteristic hallmark of the MWC Series, enabling straightforward operation and easy adjustments. The boilers come equipped with a digital display that provides critical system information and diagnostics, streamlining maintenance efforts.

Overall, the Crown Boiler MWC Series, particularly models like the MWC116ENT, MWC116ELT, MWC116ELL, and MWC116ENL, offer an impressive blend of efficiency, flexibility, and advanced technology. These units are designed to meet contemporary heating demands while ensuring sustainable operation, making them a wise investment for comfort and performance in residential and light commercial applications alike. With reliable construction and innovative features, the MWC Series remains a top choice for those seeking effective heating solutions.