available from any auto supply store. Follow the directions on the can. If the leaks are larger than 1/16" diameter, the tire can be repaired with rubber plugs also available in a kit from any auto supply store. If the tire bead is damaged, a tube will have to be installed in the tire or the tire will have to be replaced.

3.Creeping: Creeping is the slight forward or backward movement of the mower when the throttle is on and the lapbars are in the neutral position. If your mower creeps, refer to Steer- ing Lever Adjustment Section F4, page 23.

E.Brakes

While the mower is in motion, all braking is performed dynamically through the hydraulic pumps and traction motors, controlled by the two steering levers. When the mower is stationary with the engine running, the hydraulic system locks the traction wheels. If the engine is shut off, the park brake should be engaged.

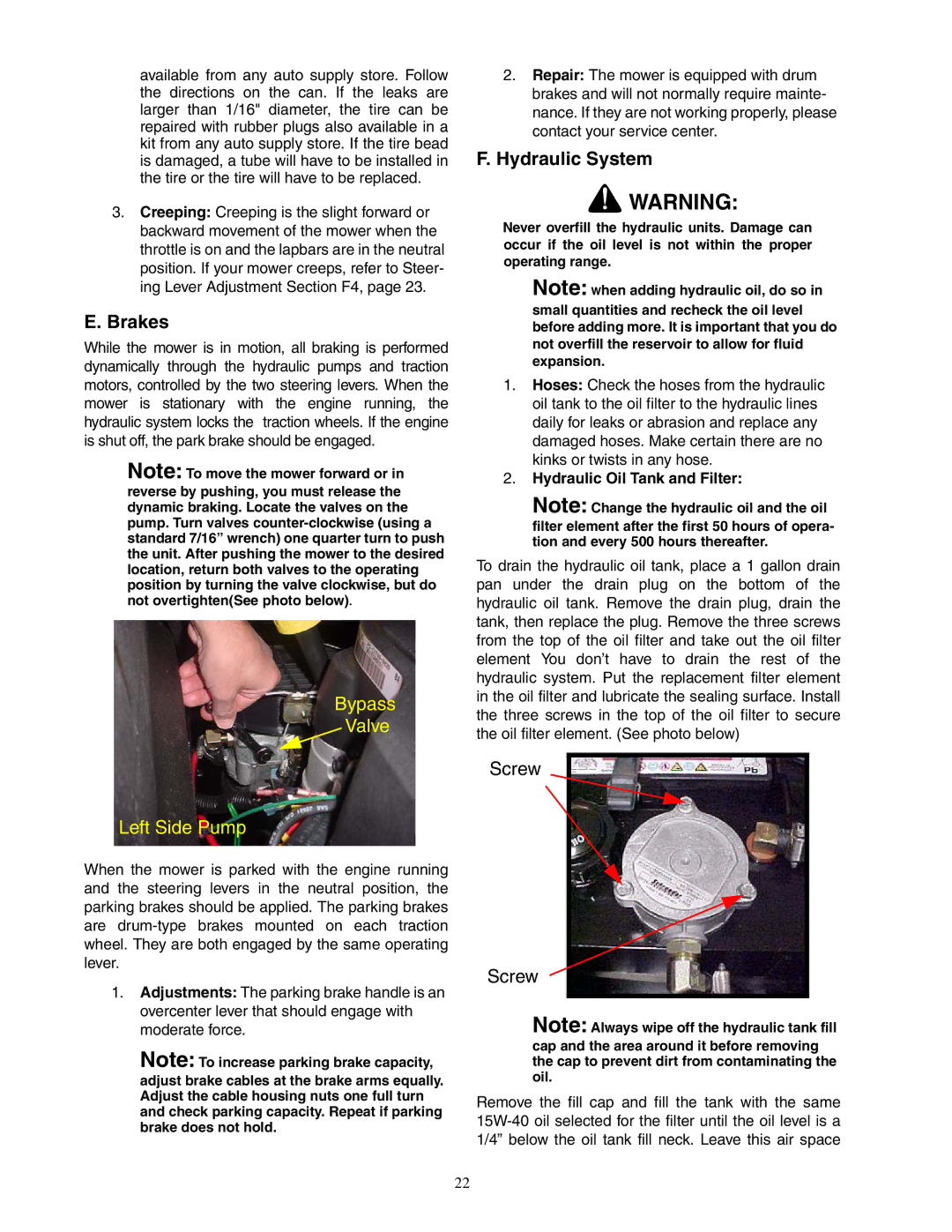

Note: To move the mower forward or in reverse by pushing, you must release the dynamic braking. Locate the valves on the pump. Turn valves

Bypass

Valve

Left Side Pump

When the mower is parked with the engine running and the steering levers in the neutral position, the parking brakes should be applied. The parking brakes are

1.Adjustments: The parking brake handle is an overcenter lever that should engage with moderate force.

Note: To increase parking brake capacity, adjust brake cables at the brake arms equally. Adjust the cable housing nuts one full turn and check parking capacity. Repeat if parking brake does not hold.

2.Repair: The mower is equipped with drum brakes and will not normally require mainte- nance. If they are not working properly, please contact your service center.

F.Hydraulic System

![]() WARNING:

WARNING:

Never overfill the hydraulic units. Damage can occur if the oil level is not within the proper operating range.

Note: When adding hydraulic oil, do so in small quantities and recheck the oil level before adding more. It is important that you do not overfill the reservoir to allow for fluid expansion.

1.Hoses: Check the hoses from the hydraulic oil tank to the oil filter to the hydraulic lines daily for leaks or abrasion and replace any damaged hoses. Make certain there are no kinks or twists in any hose.

2.Hydraulic Oil Tank and Filter:

Note: Change the hydraulic oil and the oil filter element after the first 50 hours of opera- tion and every 500 hours thereafter.

To drain the hydraulic oil tank, place a 1 gallon drain pan under the drain plug on the bottom of the hydraulic oil tank. Remove the drain plug, drain the tank, then replace the plug. Remove the three screws from the top of the oil filter and take out the oil filter element You don’t have to drain the rest of the hydraulic system. Put the replacement filter element in the oil filter and lubricate the sealing surface. Install the three screws in the top of the oil filter to secure the oil filter element. (See photo below)

Screw |

Screw |

Note: Always wipe off the hydraulic tank fill cap and the area around it before removing the cap to prevent dirt from contaminating the oil.

Remove the fill cap and fill the tank with the same

22