Section 6

18

19

20

H – High speed adjustment screw

L – Low speed needle

T – Idle adjustment screw

| 20A |

| 20B |

|

|

|

|

|

|

|

|

Carburetor Adjustment

CARBURETOR

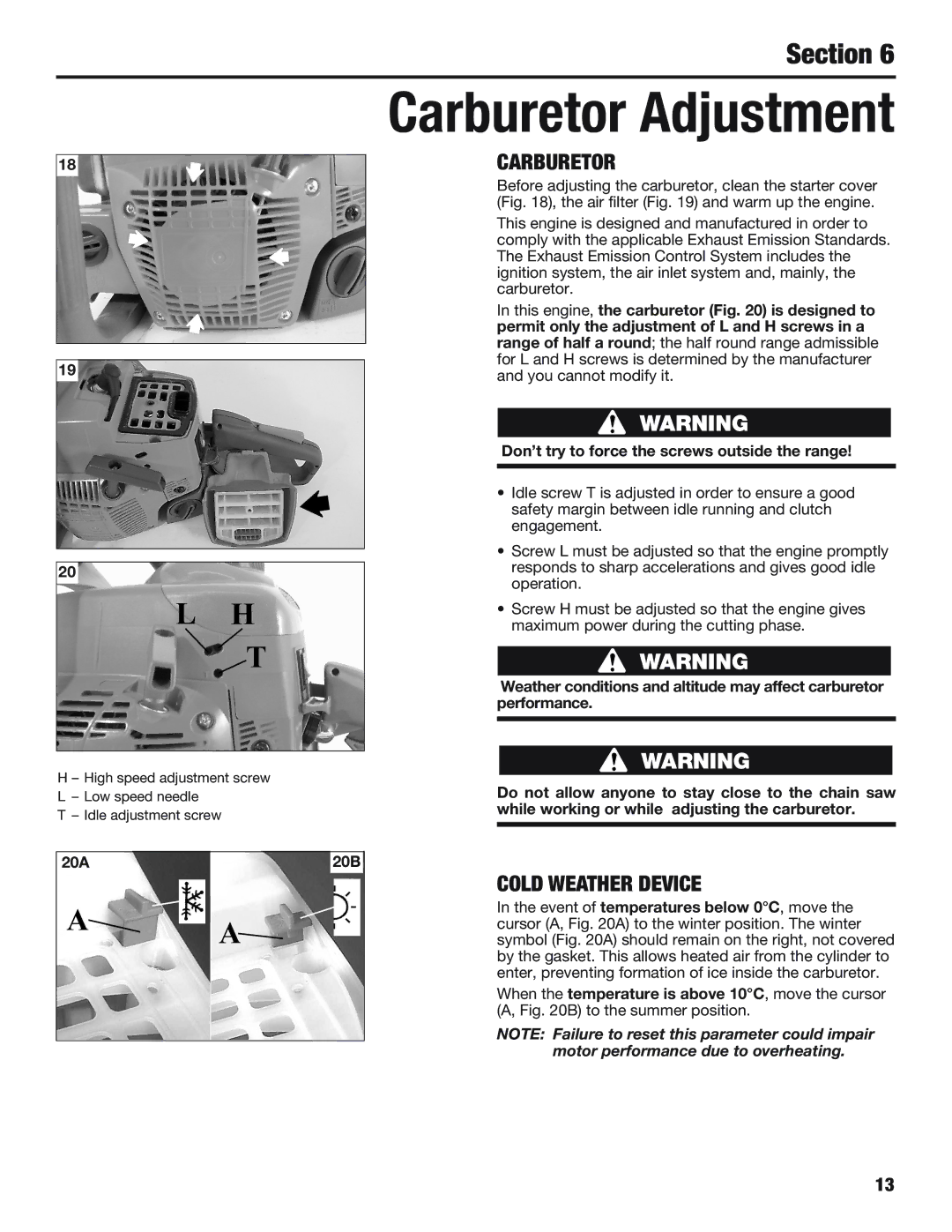

Before adjusting the carburetor, clean the starter cover (Fig. 18), the air filter (Fig. 19) and warm up the engine.

This engine is designed and manufactured in order to comply with the applicable Exhaust Emission Standards. The Exhaust Emission Control System includes the ignition system, the air inlet system and, mainly, the carburetor.

In this engine, the carburetor (Fig. 20) is designed to permit only the adjustment of L and H screws in a range of half a round; the half round range admissible for L and H screws is determined by the manufacturer and you cannot modify it.

Don’t try to force the screws outside the range!

•Idle screw T is adjusted in order to ensure a good safety margin between idle running and clutch engagement.

•Screw L must be adjusted so that the engine promptly responds to sharp accelerations and gives good idle operation.

•Screw H must be adjusted so that the engine gives maximum power during the cutting phase.

Weather conditions and altitude may affect carburetor performance.

Do not allow anyone to stay close to the chain saw while working or while adjusting the carburetor.

COLD WEATHER DEVICE

In the event of temperatures below 0°C, move the cursor (A, Fig. 20A) to the winter position. The winter symbol (Fig. 20A) should remain on the right, not covered by the gasket. This allows heated air from the cylinder to enter, preventing formation of ice inside the carburetor.

When the temperature is above 10°C, move the cursor (A, Fig. 20B) to the summer position.

NOTE: Failure to reset this parameter could impair motor performance due to overheating.

13