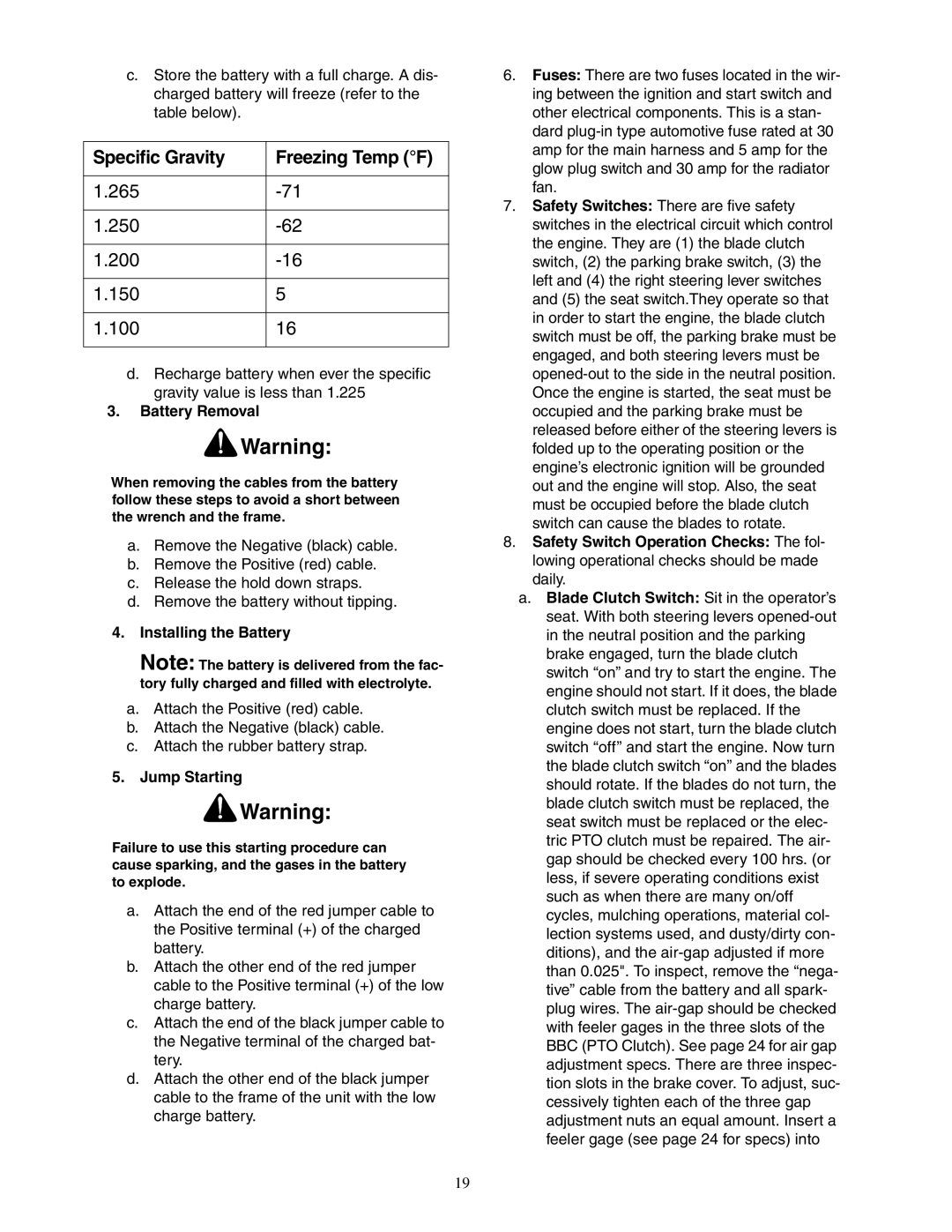

c.Store the battery with a full charge. A dis- charged battery will freeze (refer to the table below).

Specific Gravity | Freezing Temp (°F) |

|

|

1.265 | |

|

|

1.250 | |

|

|

1.200 | |

|

|

1.150 | 5 |

|

|

1.100 | 16 |

|

|

d.Recharge battery when ever the specific gravity value is less than 1.225

3.Battery Removal

![]() Warning:

Warning:

When removing the cables from the battery follow these steps to avoid a short between the wrench and the frame.

a.Remove the Negative (black) cable.

b.Remove the Positive (red) cable.

c.Release the hold down straps.

d.Remove the battery without tipping.

4.Installing the Battery

Note: The battery is delivered from the fac- tory fully charged and filled with electrolyte.

a.Attach the Positive (red) cable.

b.Attach the Negative (black) cable.

c.Attach the rubber battery strap.

5.Jump Starting

![]() Warning:

Warning:

Failure to use this starting procedure can cause sparking, and the gases in the battery to explode.

a.Attach the end of the red jumper cable to the Positive terminal (+) of the charged battery.

b.Attach the other end of the red jumper cable to the Positive terminal (+) of the low charge battery.

c.Attach the end of the black jumper cable to the Negative terminal of the charged bat- tery.

d.Attach the other end of the black jumper cable to the frame of the unit with the low charge battery.

6.Fuses: There are two fuses located in the wir- ing between the ignition and start switch and other electrical components. This is a stan- dard

7.Safety Switches: There are five safety switches in the electrical circuit which control the engine. They are (1) the blade clutch switch, (2) the parking brake switch, (3) the left and (4) the right steering lever switches and (5) the seat switch.They operate so that in order to start the engine, the blade clutch switch must be off, the parking brake must be engaged, and both steering levers must be

8.Safety Switch Operation Checks: The fol- lowing operational checks should be made daily.

a.Blade Clutch Switch: Sit in the operator’s seat. With both steering levers

19