Lubrication

WARNING: Before lubricating, repairing, or inspecting, always disengage PTO, set parking brake, stop engine and remove key to prevent unintended starting.

Engine

Refer to Engine on page 19 for instruction regarding all

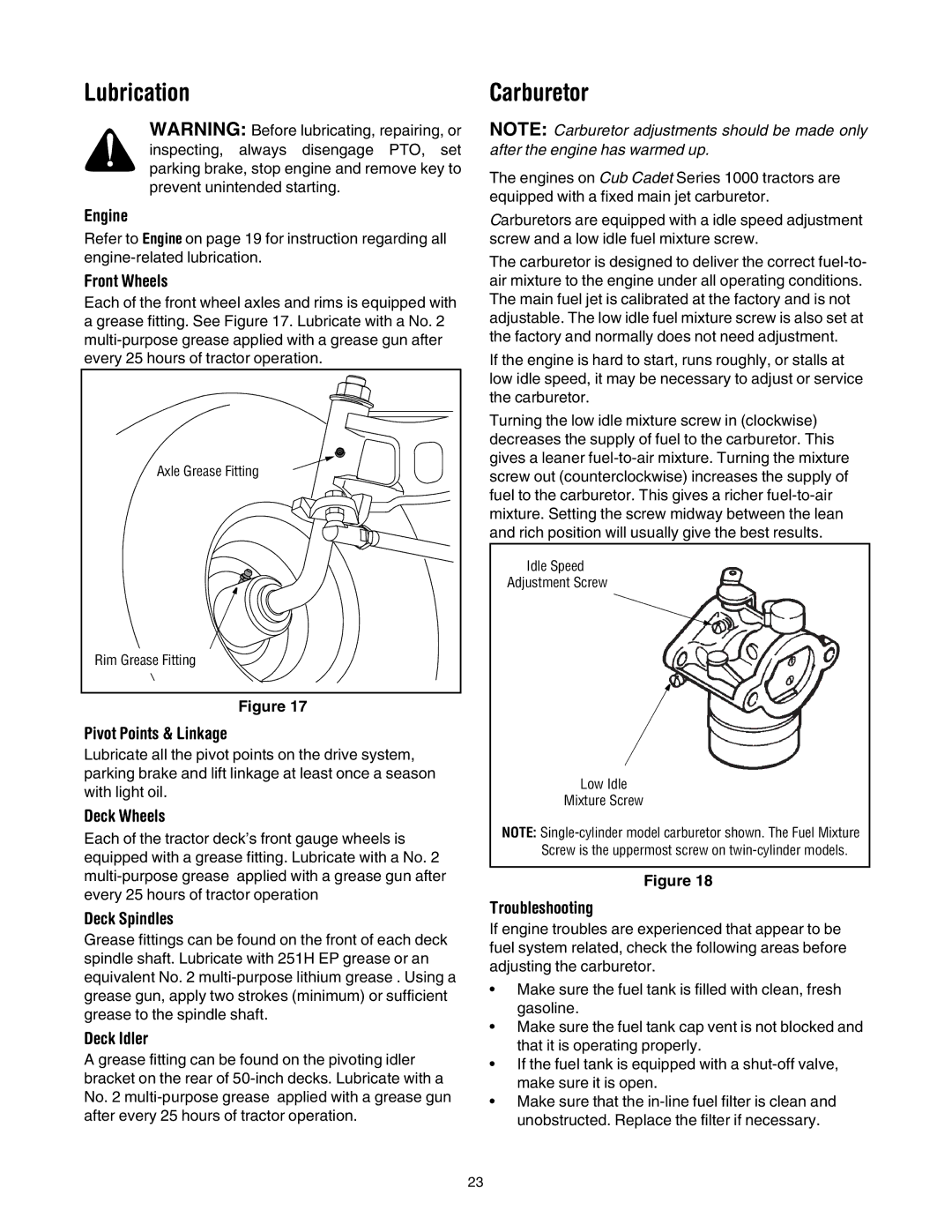

Front Wheels

Each of the front wheel axles and rims is equipped with a grease fitting. See Figure 17. Lubricate with a No. 2

Axle Grease Fitting |

Rim Grease Fitting |

Figure 17

Pivot Points & Linkage

Lubricate all the pivot points on the drive system, parking brake and lift linkage at least once a season with light oil.

Deck Wheels

Each of the tractor deck’s front gauge wheels is equipped with a grease fitting. Lubricate with a No. 2

Deck Spindles

Grease fittings can be found on the front of each deck spindle shaft. Lubricate with 251H EP grease or an equivalent No. 2

Deck Idler

A grease fitting can be found on the pivoting idler bracket on the rear of

Carburetor

NOTE: Carburetor adjustments should be made only after the engine has warmed up.

The engines on Cub Cadet Series 1000 tractors are equipped with a fixed main jet carburetor.

Carburetors are equipped with a idle speed adjustment screw and a low idle fuel mixture screw.

The carburetor is designed to deliver the correct

If the engine is hard to start, runs roughly, or stalls at low idle speed, it may be necessary to adjust or service the carburetor.

Turning the low idle mixture screw in (clockwise) decreases the supply of fuel to the carburetor. This gives a leaner

Idle Speed

Adjustment Screw

Low Idle

Mixture Screw

NOTE:

Figure 18

Troubleshooting

If engine troubles are experienced that appear to be fuel system related, check the following areas before adjusting the carburetor.

•Make sure the fuel tank is filled with clean, fresh gasoline.

•Make sure the fuel tank cap vent is not blocked and that it is operating properly.

•If the fuel tank is equipped with a

•Make sure that the

23