•Make sure fuel is reaching the carburetor. Check the fuel lines and fuel pump for restrictions or faulty components, replace as necessary.

•Make sure the air cleaner element is clean and all air cleaner element components are secure.

If, after checking the items listed above, the engine is hard to start, runs roughly, or stalls at low idle speed, it may be necessary to adjust or service the carburetor.

Adjustment

NOTE: Engines may have a fixed idle or limiter cap on the idle fuel adjusting screw. Step 2 can only be performed within the limits allowed by the cap.

1.Start the engine and run at half throttle for five to 10 minutes to warm up. The engine must be warm before performing steps 2 and 3.

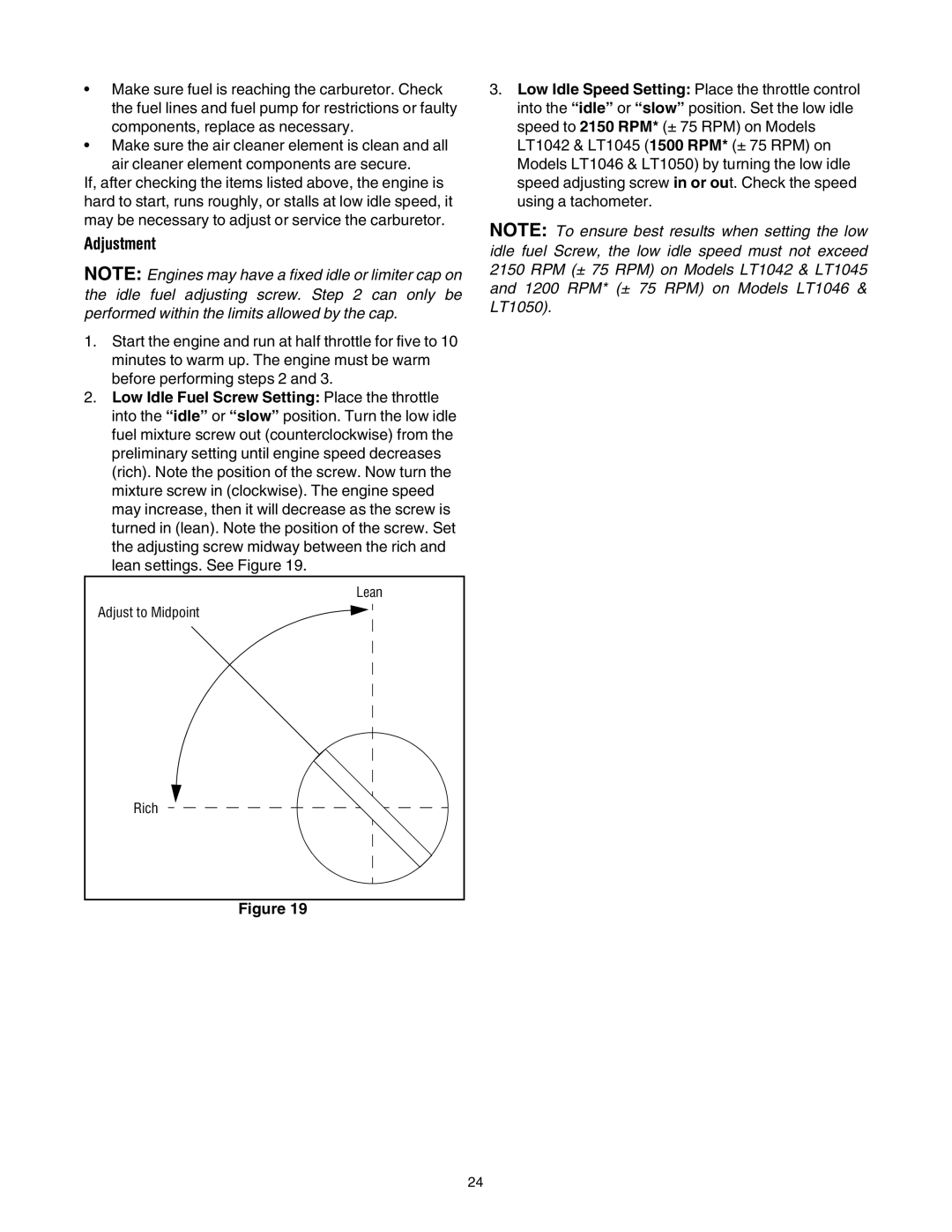

2.Low Idle Fuel Screw Setting: Place the throttle into the “idle” or “slow” position. Turn the low idle fuel mixture screw out (counterclockwise) from the preliminary setting until engine speed decreases (rich). Note the position of the screw. Now turn the mixture screw in (clockwise). The engine speed may increase, then it will decrease as the screw is turned in (lean). Note the position of the screw. Set the adjusting screw midway between the rich and lean settings. See Figure 19.

Lean

Adjust to Midpoint

Rich

3.Low Idle Speed Setting: Place the throttle control into the “idle” or “slow” position. Set the low idle speed to 2150 RPM* (± 75 RPM) on Models LT1042 & LT1045 (1500 RPM* (± 75 RPM) on Models LT1046 & LT1050) by turning the low idle speed adjusting screw in or out. Check the speed using a tachometer.

NOTE: To ensure best results when setting the low idle fuel Screw, the low idle speed must not exceed 2150 RPM (± 75 RPM) on Models LT1042 & LT1045 and 1200 RPM* (± 75 RPM) on Models LT1046 & LT1050).

Figure 19

24