Dayton Operating Instructions and Parts Manual

Models 2E510D, 2E511D, 3E218D, and 3E219C

Maintenance (Continued)

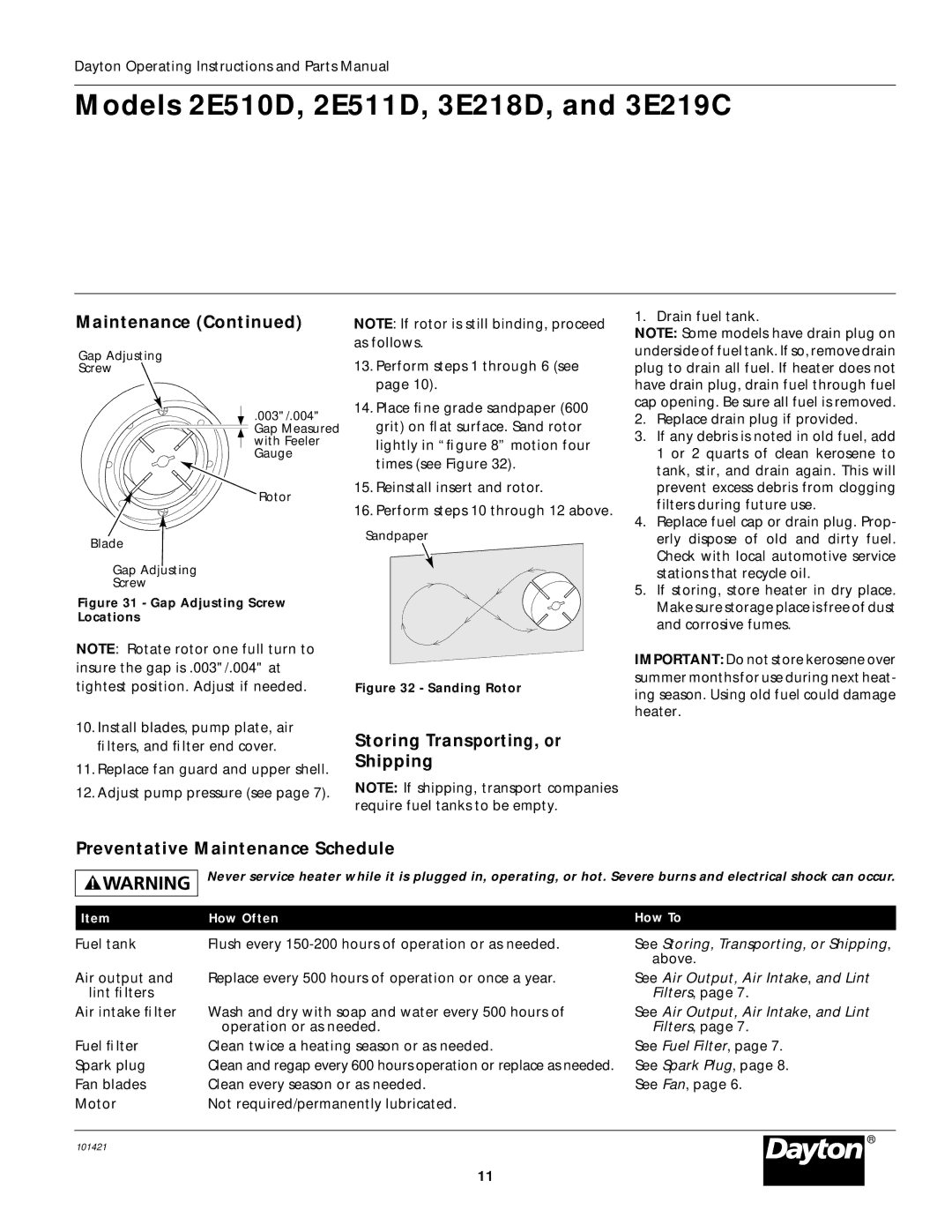

Gap Adjusting

Screw

.003"/.004"

![]() Gap Measured

Gap Measured ![]() with Feeler Gauge

with Feeler Gauge

Rotor

Blade |

Gap Adjusting |

Screw |

Figure 31 - Gap Adjusting Screw Locations

NOTE: Rotate rotor one full turn to insure the gap is .003"/.004" at tightest position. Adjust if needed.

10.Install blades, pump plate, air filters, and filter end cover.

11.Replace fan guard and upper shell.

12.Adjust pump pressure (see page 7).

NOTE: If rotor is still binding, proceed as follows.

13.Perform steps 1 through 6 (see page 10).

14.Place fine grade sandpaper (600 grit) on flat surface. Sand rotor lightly in “figure 8” motion four times (see Figure 32).

15.Reinstall insert and rotor.

16.Perform steps 10 through 12 above.

Sandpaper

Figure 32 - Sanding Rotor

Storing Transporting, or Shipping

NOTE: If shipping, transport companies require fuel tanks to be empty.

1. Drain fuel tank.

NOTE: Some models have drain plug on underside of fuel tank. If so, remove drain plug to drain all fuel. If heater does not have drain plug, drain fuel through fuel cap opening. Be sure all fuel is removed.

2.Replace drain plug if provided.

3.If any debris is noted in old fuel, add 1 or 2 quarts of clean kerosene to tank, stir, and drain again. This will prevent excess debris from clogging filters during future use.

4.Replace fuel cap or drain plug. Prop- erly dispose of old and dirty fuel. Check with local automotive service stations that recycle oil.

5.If storing, store heater in dry place. Make sure storage place is free of dust and corrosive fumes.

IMPORTANT: Do not store kerosene over summer months for use during next heat- ing season. Using old fuel could damage heater.

Preventative Maintenance Schedule

Never service heater while it is plugged in, operating, or hot. Severe burns and electrical shock can occur.

Item | How Often | How To |

|

|

|

Fuel tank | Flush every |

See Storing, Transporting, or Shipping, above.

Air output and | Replace every 500 hours of operation or once a year. | See Air Output, Air Intake, and Lint |

lint filters |

| Filters, page 7. |

Air intake filter | Wash and dry with soap and water every 500 hours of | See Air Output, Air Intake, and Lint |

| operation or as needed. | Filters, page 7. |

Fuel filter | Clean twice a heating season or as needed. | See Fuel Filter, page 7. |

Spark plug | Clean and regap every 600 hours operation or replace as needed. | See Spark Plug, page 8. |

Fan blades | Clean every season or as needed. | See Fan, page 6. |

Motor | Not required/permanently lubricated. |

|

|

|

|

101421 |

| ® |

|

|

11