J E O L J S M - 6 0 6 0 L V S C A N N I N G E L E C T R O N M I C R O S C O P E

The basic components of a SEM are the vacuum system, electron gun, lens system, electron detector, imaging system, and the electronics associated with these components. The vacuum system is necessary to minimize the interference of air particles with the electron beam and to prevent rapid oxidation of the tungsten filament. The vacuum system consists of roughing pumps, an oil diffusion pump, and various vacuum fittings, valves and seals that provide a working pressure in the SEM of

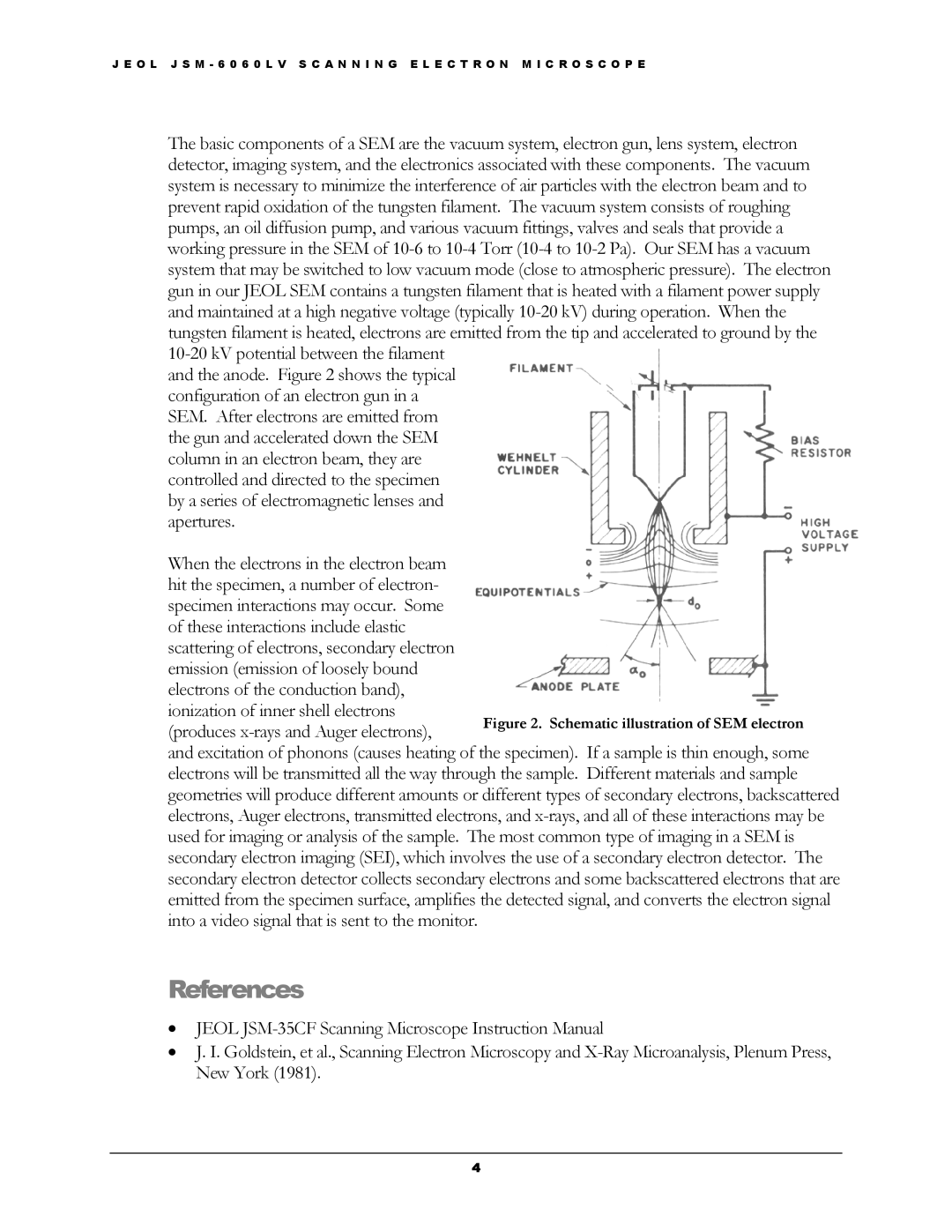

and the anode. Figure 2 shows the typical configuration of an electron gun in a SEM. After electrons are emitted from the gun and accelerated down the SEM column in an electron beam, they are controlled and directed to the specimen by a series of electromagnetic lenses and apertures.

When the electrons in the electron beam hit the specimen, a number of electron- specimen interactions may occur. Some of these interactions include elastic scattering of electrons, secondary electron emission (emission of loosely bound electrons of the conduction band), ionization of inner shell electrons (produces

and excitation of phonons (causes heating of the specimen). If a sample is thin enough, some electrons will be transmitted all the way through the sample. Different materials and sample geometries will produce different amounts or different types of secondary electrons, backscattered electrons, Auger electrons, transmitted electrons, and

References

•JEOL

•J. I. Goldstein, et al., Scanning Electron Microscopy and

4