INJECTORS TABLE

| NOMINAL | REDUCED | LP/PROPANE | NATURAL GAS | |||

| POWER | POWER | 11” W.C.P. | 4” W.C.P. | |||

BURNERS | BTU/hr | BTU/hr | Ø injector | Ø injector | |||

[1/100 mm] | [1/100 mm] | [1/100 mm] | [1/100 mm] | ||||

|

|

| |||||

|

|

|

|

|

|

| |

Auxiliary (AUX) | 3500 | 1000 | 55 | 27 | 90 | adjustable | |

|

|

|

|

|

|

| |

Semirapid (SR) | 6000 | 1500 | 72 | 32 | 118 | adjustable | |

|

|

|

|

|

|

| |

Triple ring (TC) | 12000 | 5000 | 102 | 65 | 170 | adjustable | |

|

|

|

|

|

|

| |

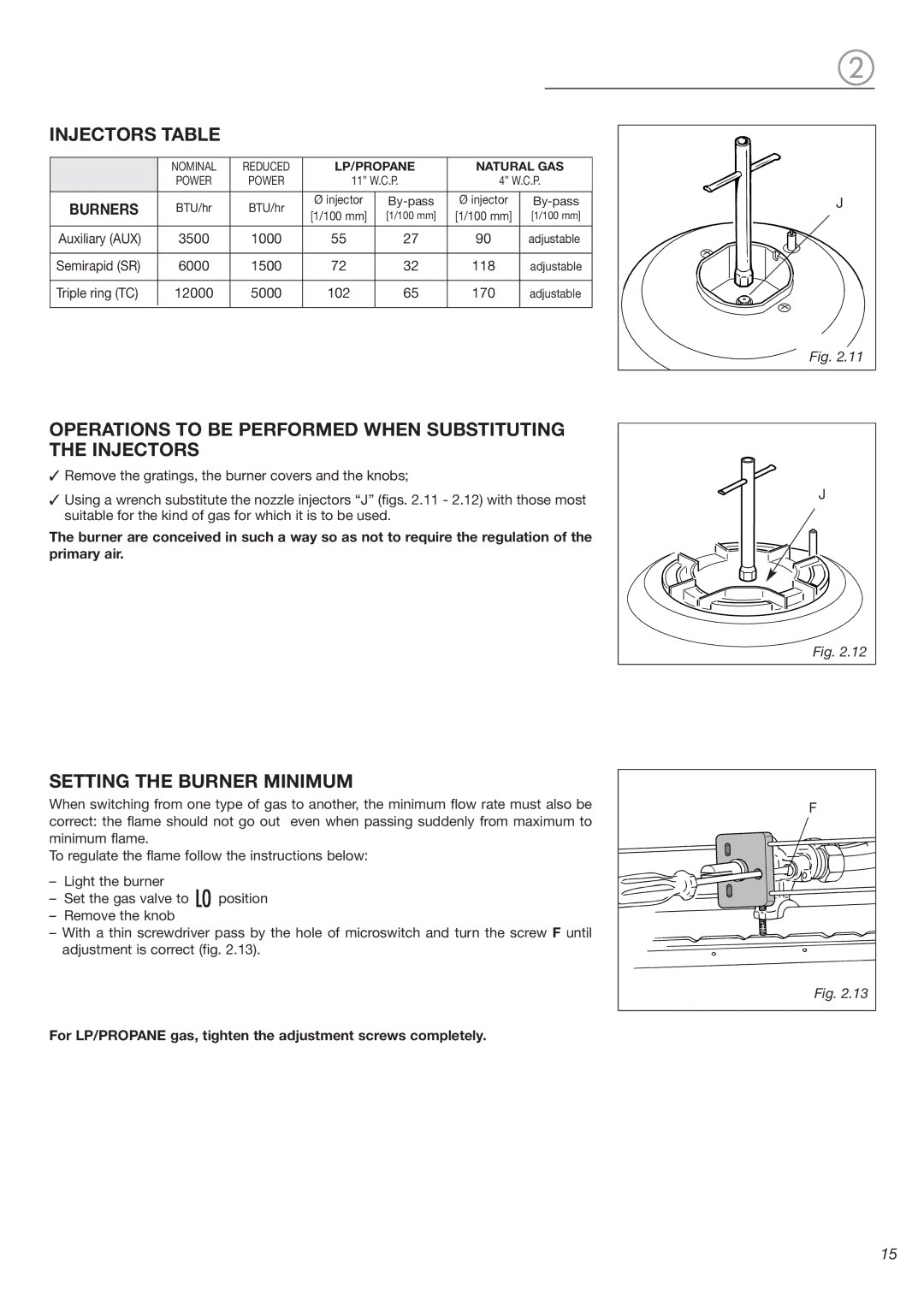

OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING THE INJECTORS

✓Remove the gratings, the burner covers and the knobs;

✓Using a wrench substitute the nozzle injectors “J” (figs. 2.11 - 2.12) with those most suitable for the kind of gas for which it is to be used.

The burner are conceived in such a way so as not to require the regulation of the primary air.

J

Fig. 2.11

J

Fig. 2.12

SETTING THE BURNER MINIMUM |

| ||

When switching from one type of gas to another, the minimum flow rate must also be | F | ||

correct: the flame should not go out even when passing suddenly from maximum to |

| ||

minimum flame. |

|

| |

To regulate the flame follow the instructions below: |

| ||

– | Light the burner |

|

|

– | Set the gas valve to | position |

|

– Remove the knob |

|

| |

– With a thin screwdriver pass by the hole of microswitch and turn the screw F until |

| ||

| adjustment is correct (fig. 2.13). |

| |

Fig. 2.13

For LP/PROPANE gas, tighten the adjustment screws completely.

15