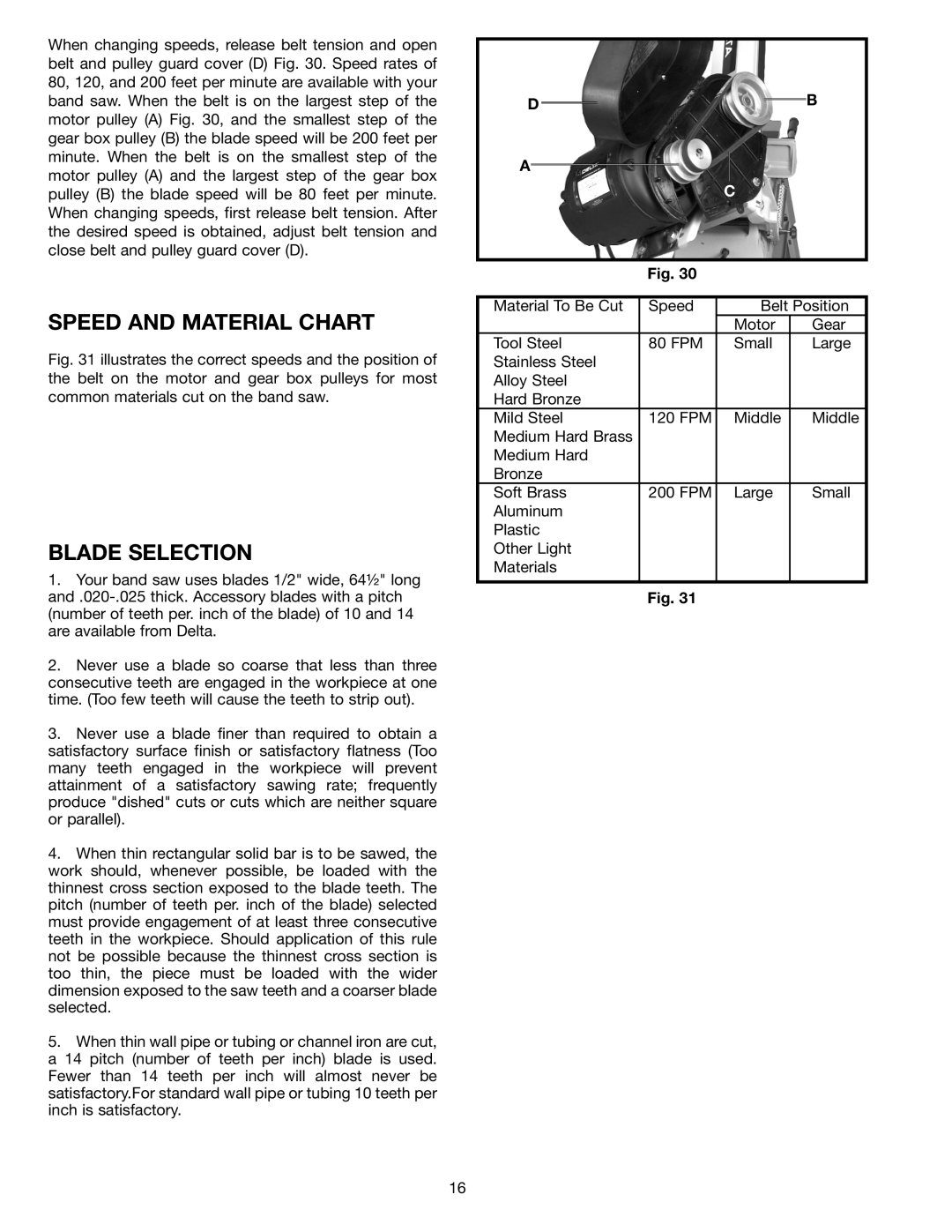

When changing speeds, release belt tension and open belt and pulley guard cover (D) Fig. 30. Speed rates of 80, 120, and 200 feet per minute are available with your band saw. When the belt is on the largest step of the motor pulley (A) Fig. 30, and the smallest step of the gear box pulley (B) the blade speed will be 200 feet per minute. When the belt is on the smallest step of the motor pulley (A) and the largest step of the gear box pulley (B) the blade speed will be 80 feet per minute. When changing speeds, first release belt tension. After the desired speed is obtained, adjust belt tension and close belt and pulley guard cover (D).

SPEED AND MATERIAL CHART

Fig. 31 illustrates the correct speeds and the position of the belt on the motor and gear box pulleys for most common materials cut on the band saw.

BLADE SELECTION

1.Your band saw uses blades 1/2" wide, 64½" long

2.Never use a blade so coarse that less than three consecutive teeth are engaged in the workpiece at one time. (Too few teeth will cause the teeth to strip out).

3.Never use a blade finer than required to obtain a satisfactory surface finish or satisfactory flatness (Too many teeth engaged in the workpiece will prevent attainment of a satisfactory sawing rate; frequently produce "dished" cuts or cuts which are neither square or parallel).

4.When thin rectangular solid bar is to be sawed, the work should, whenever possible, be loaded with the thinnest cross section exposed to the blade teeth. The pitch (number of teeth per. inch of the blade) selected must provide engagement of at least three consecutive teeth in the workpiece. Should application of this rule not be possible because the thinnest cross section is too thin, the piece must be loaded with the wider dimension exposed to the saw teeth and a coarser blade selected.

5.When thin wall pipe or tubing or channel iron are cut, a 14 pitch (number of teeth per inch) blade is used. Fewer than 14 teeth per inch will almost never be satisfactory.For standard wall pipe or tubing 10 teeth per inch is satisfactory.

D |

|

|

|

|

|

|

|

| B | |

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

| |||

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Fig. 30 |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

Material To Be Cut | Speed |

| Belt Position | |||||||

|

|

|

|

|

|

| Motor |

| Gear | |

Tool Steel | 80 FPM |

| Small |

| Large | |||||

Stainless Steel |

|

|

|

|

|

|

| |||

Alloy Steel |

|

|

|

|

|

|

| |||

Hard Bronze |

|

|

|

|

|

|

| |||

Mild Steel | 120 FPM |

| Middle |

| Middle | |||||

Medium Hard Brass |

|

|

|

|

|

|

| |||

Medium Hard |

|

|

|

|

|

|

| |||

Bronze |

|

|

|

|

|

|

| |||

Soft Brass | 200 FPM |

| Large |

| Small | |||||

Aluminum |

|

|

|

|

|

|

| |||

Plastic |

|

|

|

|

|

|

| |||

Other Light |

|

|

|

|

|

|

| |||

Materials |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Fig. 31 |

|

|

|

|

| |

16