ADJUSTING BLADE TENSION

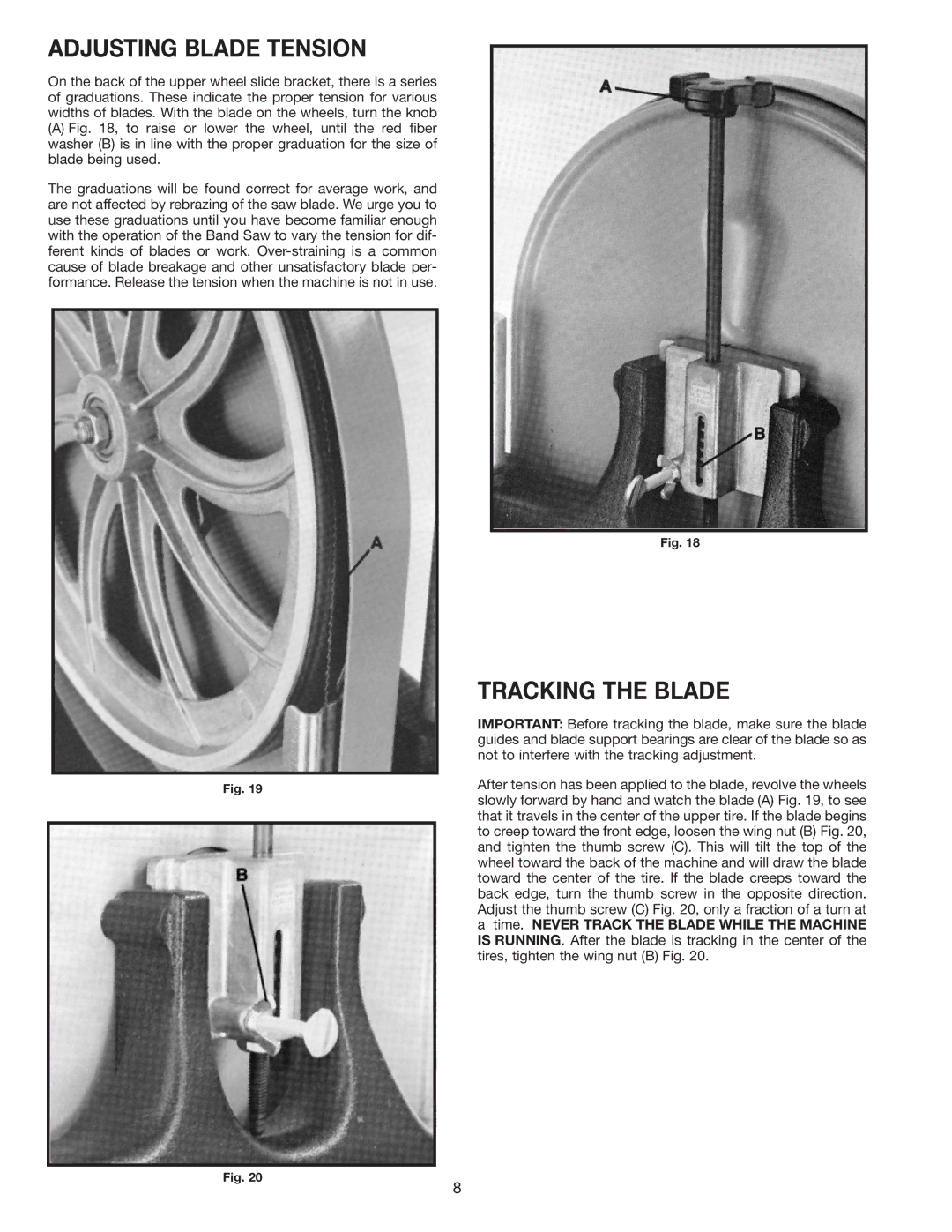

On the back of the upper wheel slide bracket, there is a series of graduations. These indicate the proper tension for various widths of blades. With the blade on the wheels, turn the knob

(A)Fig. 18, to raise or lower the wheel, until the red fiber washer (B) is in line with the proper graduation for the size of blade being used.

The graduations will be found correct for average work, and are not affected by rebrazing of the saw blade. We urge you to use these graduations until you have become familiar enough with the operation of the Band Saw to vary the tension for dif- ferent kinds of blades or work.

Fig. 19

Fig. 20

Fig. 18

TRACKING THE BLADE

IMPORTANT: Before tracking the blade, make sure the blade guides and blade support bearings are clear of the blade so as not to interfere with the tracking adjustment.

After tension has been applied to the blade, revolve the wheels slowly forward by hand and watch the blade (A) Fig. 19, to see that it travels in the center of the upper tire. If the blade begins to creep toward the front edge, loosen the wing nut (B) Fig. 20, and tighten the thumb screw (C). This will tilt the top of the wheel toward the back of the machine and will draw the blade toward the center of the tire. If the blade creeps toward the back edge, turn the thumb screw in the opposite direction. Adjust the thumb screw (C) Fig. 20, only a fraction of a turn at

atime. NEVER TRACK THE BLADE WHILE THE MACHINE IS RUNNING. After the blade is tracking in the center of the tires, tighten the wing nut (B) Fig. 20.

8