EXTENSION CORDS

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Use proper extension cords. Make sure your extension cord is in good condition and is a

Use proper extension cords. Make sure your extension cord is in good condition and is a

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere | Volts | Total Length | Gauge of Extension | |

Rating |

| of Cord in | Cord | |

|

| Feet |

| |

120 | up to 25 | 18 AWG | ||

120 | 16 AWG | |||

120 | 16 AWG | |||

120 | 14 AWG | |||

120 | up to 25 | 18 AWG | ||

120 | 16 AWG | |||

120 | 14 AWG | |||

120 | 12 AWG | |||

120 | up to 25 | 16 AWG | ||

120 | 16 AWG | |||

120 | 14 AWG | |||

120 | 12 AWG | |||

120 | up to 25 | 14 AWG | ||

120 | 12 AWG | |||

120 |

|

| ||

GREATER THAN 50 FEET NOT RECOMMENDED | ||||

|

| |||

|

|

|

| |

|

| FIG. C |

| |

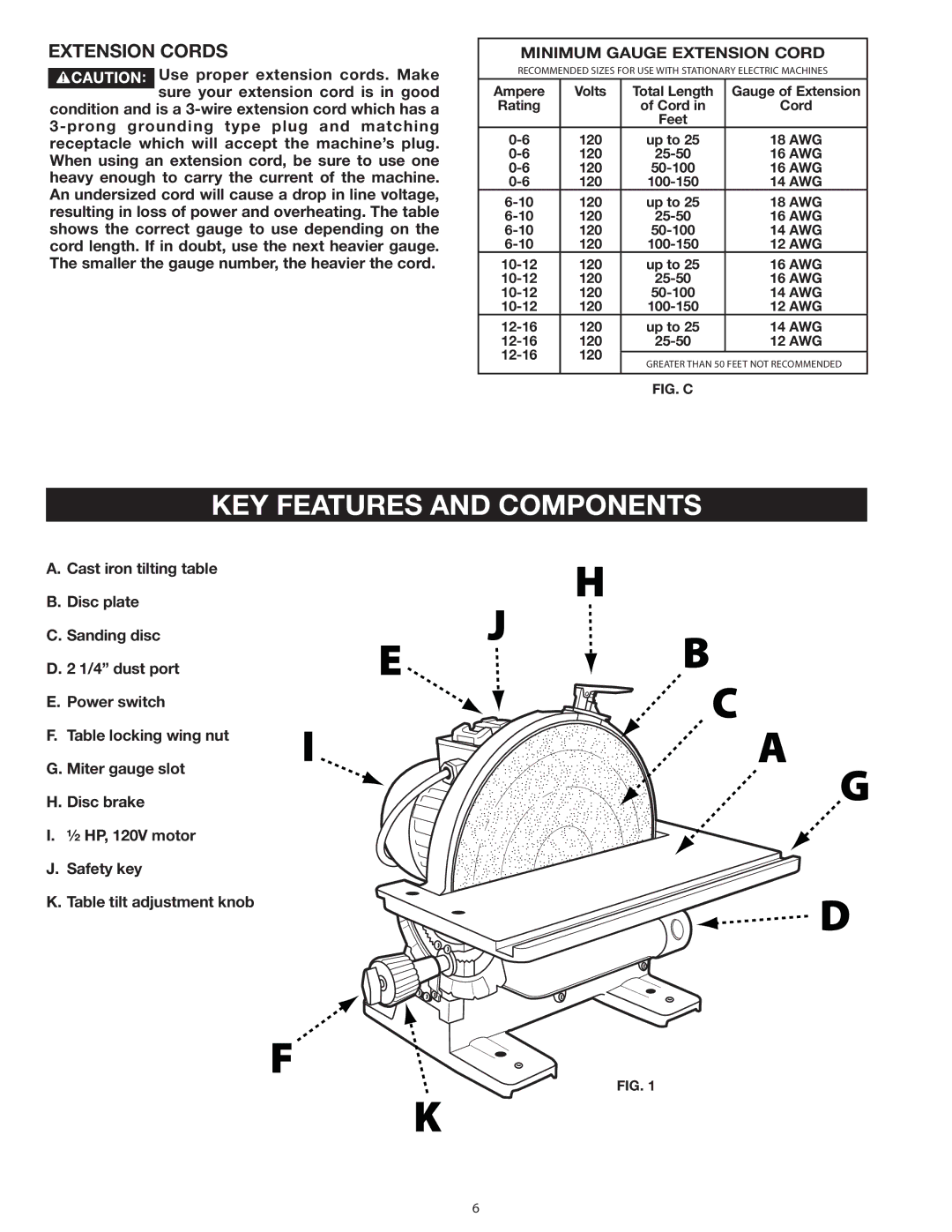

KEY FEATURES AND COMPONENTS

A.Cast iron tilting table

B.Disc plate

C. Sanding disc

D. 2 1/4” dust port

E. Power switch

F. Table locking wing nut

G. Miter gauge slot

H. Disc brake

I. ½ HP, 120V motor

J. Safety key

K. Table tilt adjustment knob

FIG. 1

6