POINTER AND SCALE

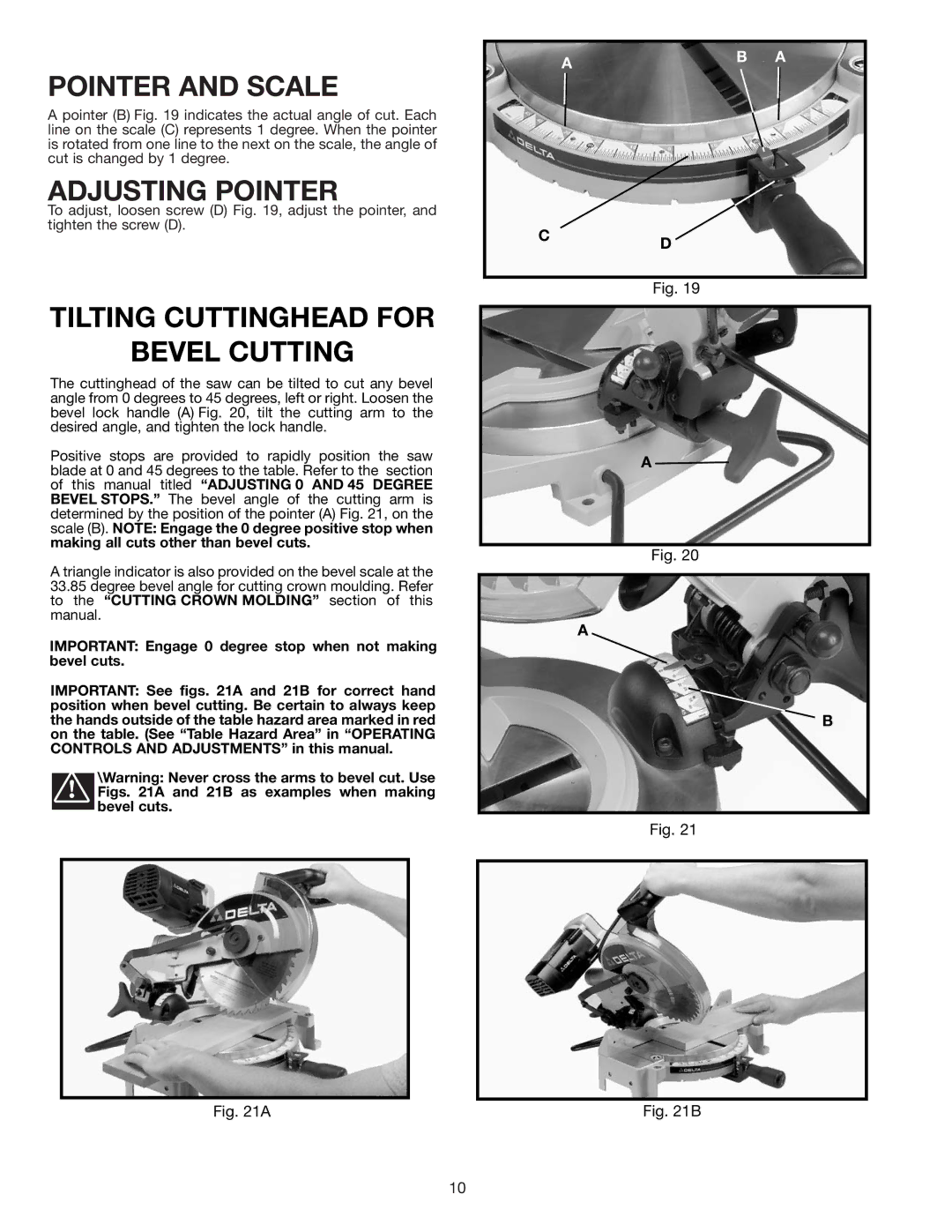

A pointer (B) Fig. 19 indicates the actual angle of cut. Each line on the scale (C) represents 1 degree. When the pointer is rotated from one line to the next on the scale, the angle of cut is changed by 1 degree.

ADJUSTING POINTER

To adjust, loosen screw (D) Fig. 19, adjust the pointer, and tighten the screw (D).

TILTING CUTTINGHEAD FOR

BEVEL CUTTING

The cuttinghead of the saw can be tilted to cut any bevel angle from 0 degrees to 45 degrees, left or right. Loosen the bevel lock handle (A) Fig. 20, tilt the cutting arm to the desired angle, and tighten the lock handle.

Positive stops are provided to rapidly position the saw blade at 0 and 45 degrees to the table. Refer to the section of this manual titled “ADJUSTING 0 AND 45 DEGREE BEVEL STOPS.” The bevel angle of the cutting arm is determined by the position of the pointer (A) Fig. 21, on the scale (B). NOTE: Engage the 0 degree positive stop when making all cuts other than bevel cuts.

A triangle indicator is also provided on the bevel scale at the

33.85degree bevel angle for cutting crown moulding. Refer to the “CUTTING CROWN MOLDING” section of this manual.

IMPORTANT: Engage 0 degree stop when not making bevel cuts.

IMPORTANT: See figs. 21A and 21B for correct hand position when bevel cutting. Be certain to always keep the hands outside of the table hazard area marked in red on the table. (See “Table Hazard Area” in “OPERATING CONTROLS AND ADJUSTMENTS” in this manual.

\Warning: Never cross the arms to bevel cut. Use Figs. 21A and 21B as examples when making bevel cuts.

AB A

CD

Fig. 19

A ![]()

Fig. 20

A

B

Fig. 21

Fig. 21A | Fig. 21B |

10