ADJUSTING CHIP DEFLECTOR

1. DISCONNECT THE MACHINE FROM

DISCONNECT THE MACHINE FROM

THE POWER SOURCE.

2.A chip deflector (A) Fig. 22, is supplied to help prevent scrap or

ADJUSTING 0° AND 45° BEVEL POSITIVE STOPS

1.![]() DISCONNECT THE MACHINE FROM

DISCONNECT THE MACHINE FROM

THE POWER SOURCE.

2.Adjust saw so that both bevel and miter pointers are set at 0°. Tighten bevel lock handle and lock cuttinghead in down position.

3.Place one end of a square (A) Fig. 23 on the table and the other end against the blade. The blade should be set at 90° to the table.

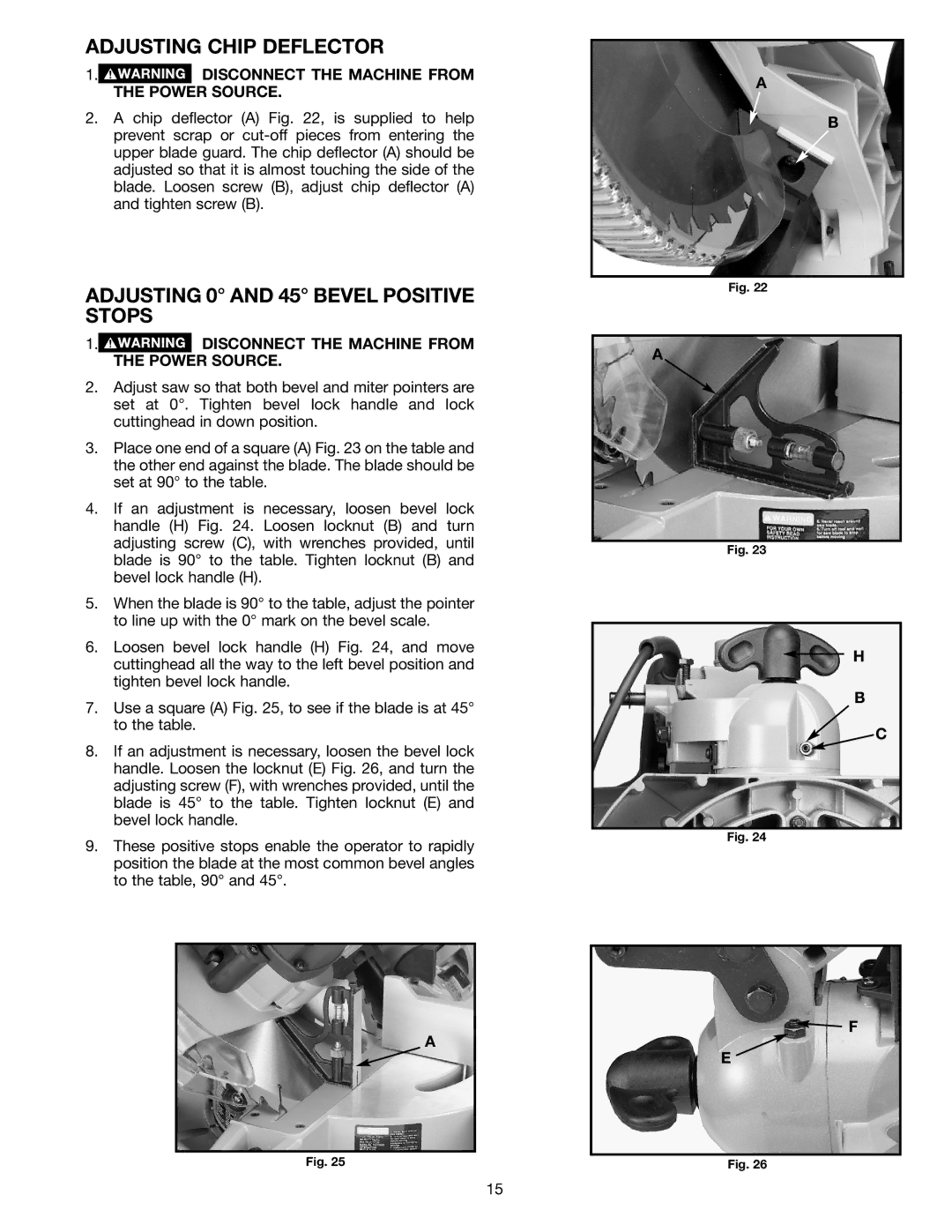

4.If an adjustment is necessary, loosen bevel lock handle (H) Fig. 24. Loosen locknut (B) and turn adjusting screw (C), with wrenches provided, until blade is 90° to the table. Tighten locknut (B) and bevel lock handle (H).

5.When the blade is 90° to the table, adjust the pointer to line up with the 0° mark on the bevel scale.

6.Loosen bevel lock handle (H) Fig. 24, and move cuttinghead all the way to the left bevel position and tighten bevel lock handle.

7.Use a square (A) Fig. 25, to see if the blade is at 45° to the table.

8.If an adjustment is necessary, loosen the bevel lock handle. Loosen the locknut (E) Fig. 26, and turn the adjusting screw (F), with wrenches provided, until the blade is 45° to the table. Tighten locknut (E) and bevel lock handle.

9.These positive stops enable the operator to rapidly position the blade at the most common bevel angles to the table, 90° and 45°.

A

Fig. 25

A

B

Fig. 22

A

Fig. 23

H

B

![]() C

C

Fig. 24

![]() F

F

E

Fig. 26

15