LASER USE AND ADJUSTMENTS

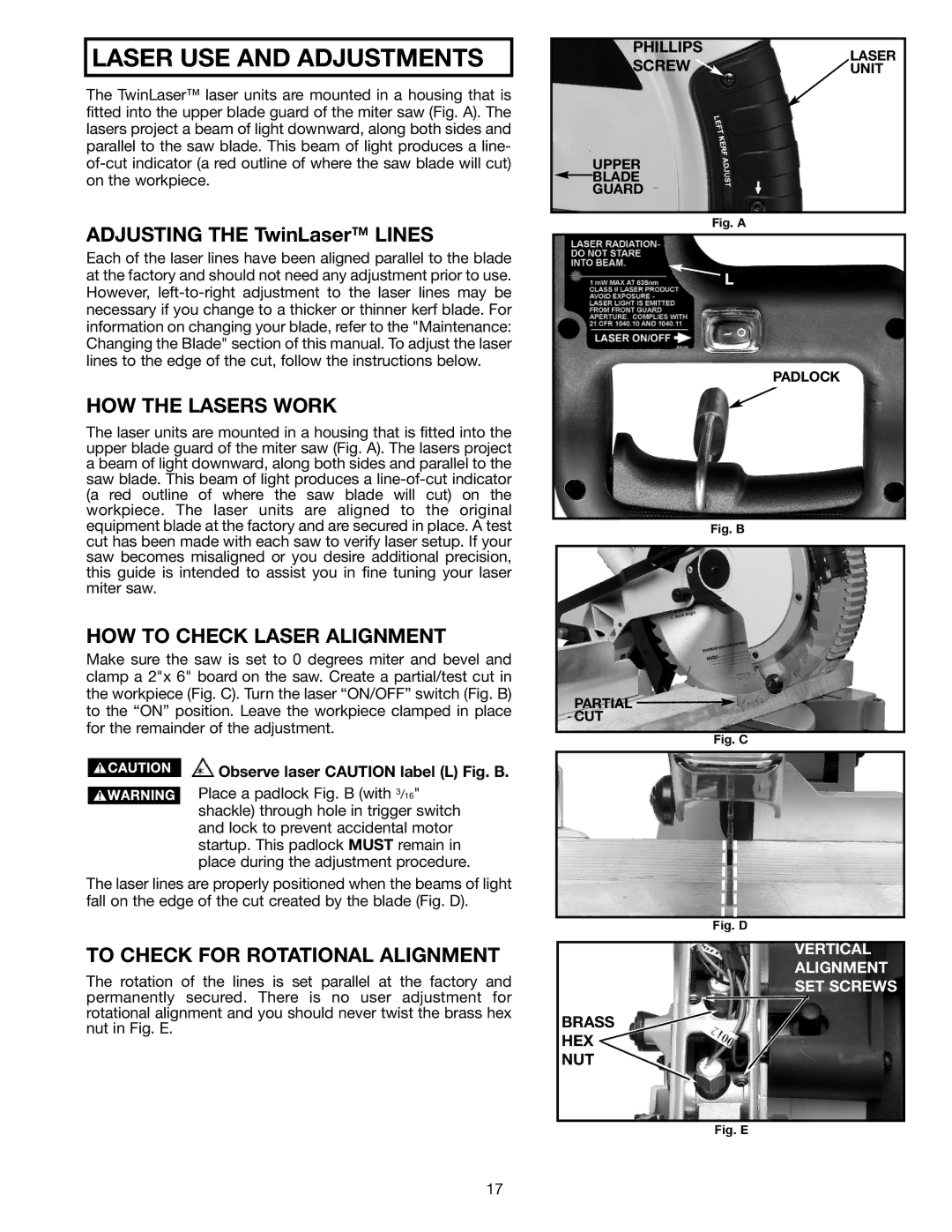

The TwinLaser™ laser units are mounted in a housing that is fitted into the upper blade guard of the miter saw (Fig. A). The lasers project a beam of light downward, along both sides and parallel to the saw blade. This beam of light produces a line-

ADJUSTING THE TwinLaser™ LINES

Each of the laser lines have been aligned parallel to the blade at the factory and should not need any adjustment prior to use. However,

HOW THE LASERS WORK

The laser units are mounted in a housing that is fitted into the upper blade guard of the miter saw (Fig. A). The lasers project a beam of light downward, along both sides and parallel to the saw blade. This beam of light produces a

HOW TO CHECK LASER ALIGNMENT

Make sure the saw is set to 0 degrees miter and bevel and clamp a 2"x 6" board on the saw. Create a partial/test cut in the workpiece (Fig. C). Turn the laser “ON/OFF” switch (Fig. B) to the “ON” position. Leave the workpiece clamped in place for the remainder of the adjustment.

Observe laser CAUTION label (L) Fig. B.

Observe laser CAUTION label (L) Fig. B.

Place a padlock Fig. B (with 3/16" shackle) through hole in trigger switch and lock to prevent accidental motor startup. This padlock MUST remain in place during the adjustment procedure.

The laser lines are properly positioned when the beams of light fall on the edge of the cut created by the blade (Fig. D).

TO CHECK FOR ROTATIONAL ALIGNMENT

The rotation of the lines is set parallel at the factory and permanently secured. There is no user adjustment for rotational alignment and you should never twist the brass hex nut in Fig. E.

PHILLIPS | LASER | |

SCREW | ||

UNIT |

UPPER

![]() BLADE

BLADE

GUARD

Fig. A

L

PADLOCK

Fig. B

PARTIAL

CUT

Fig. C

Fig. D

VERTICAL

ALIGNMENT

SET SCREWS

BRASS

HEX

NUT

Fig. E

17