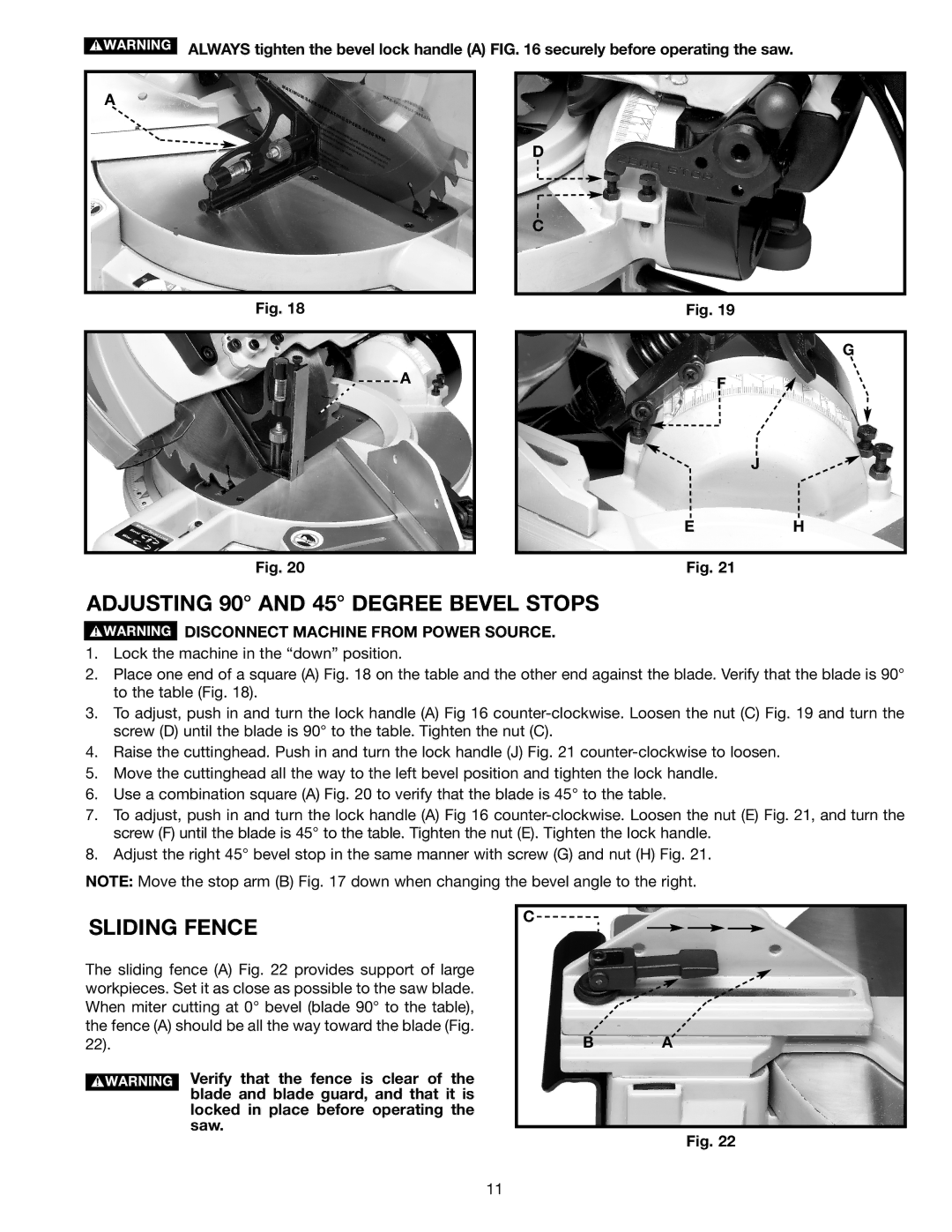

ALWAYS tighten the bevel lock handle (A) FIG. 16 securely before operating the saw.

A

D

C

Fig. 18 |

| Fig. 19 |

|

| G |

| A | F |

|

|

|

| J |

| E | H |

Fig. 20 | Fig. 21 |

|

ADJUSTING 90° AND 45° DEGREE BEVEL STOPS

DISCONNECT MACHINE FROM POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE.

1.Lock the machine in the “down” position.

2.Place one end of a square (A) Fig. 18 on the table and the other end against the blade. Verify that the blade is 90° to the table (Fig. 18).

3.To adjust, push in and turn the lock handle (A) Fig 16

4.Raise the cuttinghead. Push in and turn the lock handle (J) Fig. 21

5.Move the cuttinghead all the way to the left bevel position and tighten the lock handle.

6.Use a combination square (A) Fig. 20 to verify that the blade is 45° to the table.

7.To adjust, push in and turn the lock handle (A) Fig 16

8.Adjust the right 45° bevel stop in the same manner with screw (G) and nut (H) Fig. 21.

NOTE: Move the stop arm (B) Fig. 17 down when changing the bevel angle to the right.

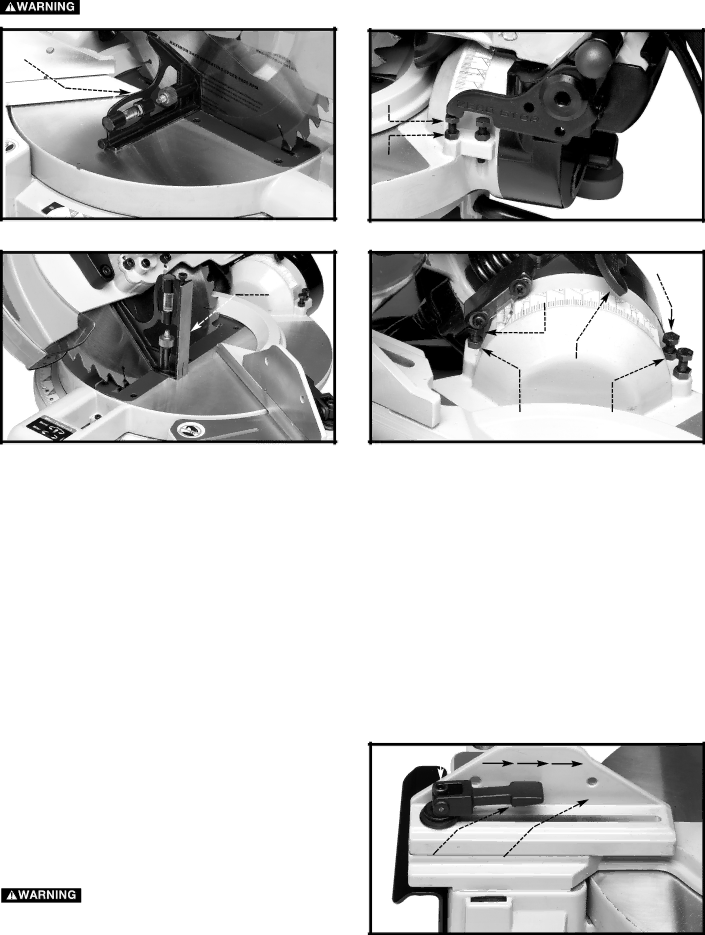

SLIDING FENCE

The sliding fence (A) Fig. 22 provides support of large workpieces. Set it as close as possible to the saw blade. When miter cutting at 0° bevel (blade 90° to the table), the fence (A) should be all the way toward the blade (Fig. 22).

Verify that the fence is clear of the blade and blade guard, and that it is locked in place before operating the saw.

C![]()

B A

Fig. 22

11