LUBRICATION

To keep the scroll saw operating at peak efficiency, we recommend that a simple maintenance procedure be performed after each 20 hours of use (approximately) as follows:

1.MAKE CERTAIN THE MACHINE IS DISCON- NECTED FROM THE POWER SOURCE.

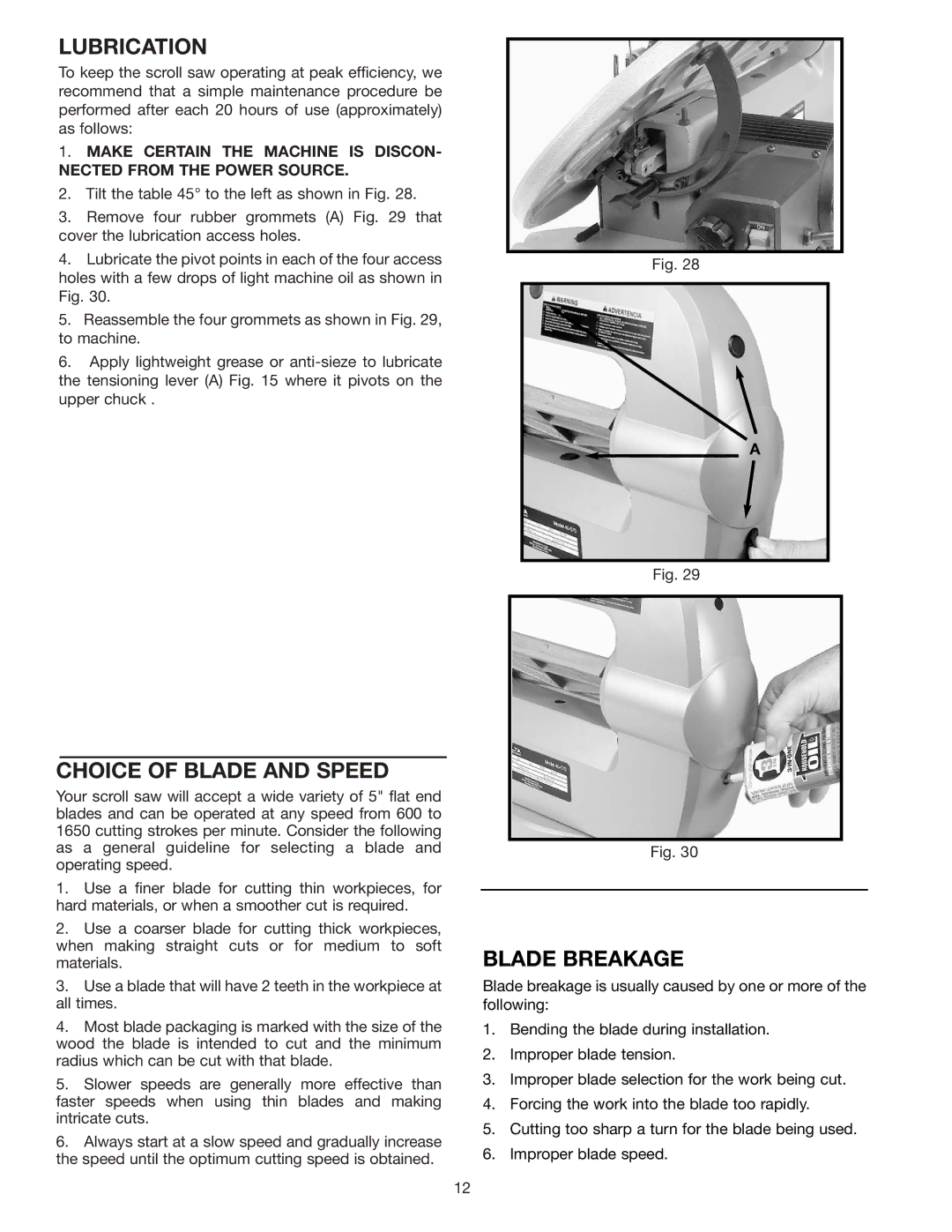

2.Tilt the table 45° to the left as shown in Fig. 28.

3.Remove four rubber grommets (A) Fig. 29 that cover the lubrication access holes.

4.Lubricate the pivot points in each of the four access holes with a few drops of light machine oil as shown in Fig. 30.

5.Reassemble the four grommets as shown in Fig. 29, to machine.

6.Apply lightweight grease or

CHOICE OF BLADE AND SPEED

Your scroll saw will accept a wide variety of 5" flat end blades and can be operated at any speed from 600 to 1650 cutting strokes per minute. Consider the following as a general guideline for selecting a blade and operating speed.

1.Use a finer blade for cutting thin workpieces, for hard materials, or when a smoother cut is required.

2.Use a coarser blade for cutting thick workpieces, when making straight cuts or for medium to soft materials.

3.Use a blade that will have 2 teeth in the workpiece at all times.

4.Most blade packaging is marked with the size of the wood the blade is intended to cut and the minimum radius which can be cut with that blade.

5.Slower speeds are generally more effective than faster speeds when using thin blades and making intricate cuts.

6.Always start at a slow speed and gradually increase the speed until the optimum cutting speed is obtained.

Fig. 28

A

Fig. 29

Fig. 30

BLADE BREAKAGE

Blade breakage is usually caused by one or more of the following:

1.Bending the blade during installation.

2.Improper blade tension.

3.Improper blade selection for the work being cut.

4.Forcing the work into the blade too rapidly.

5.Cutting too sharp a turn for the blade being used.

6.Improper blade speed.

12