FOLLOWING A LINE

With your scroll saw you should be able to cut a straight or curved line with ease. Most beginners will experience blade wandering, however, they eventually learn to control it as they become more familiar with the machine. Use scrap material to practice cuts before starting a project. This enables you to develop your own way of cutting and you will find out what you can and cannot do with your saw.

Always hold the work firmly against the table and do not feed the workpiece too fast while cutting. Feed the workpiece only fast enough so that the blade will cut. Scroll saws cut faster across the grain than they do with the grain. Allow for this tendency when cutting patterns that shift rather quickly from

Make “relief” cuts before cutting long curves and never attempt to cut a curve that is too tight for the blade being used.

ACCESSORIES

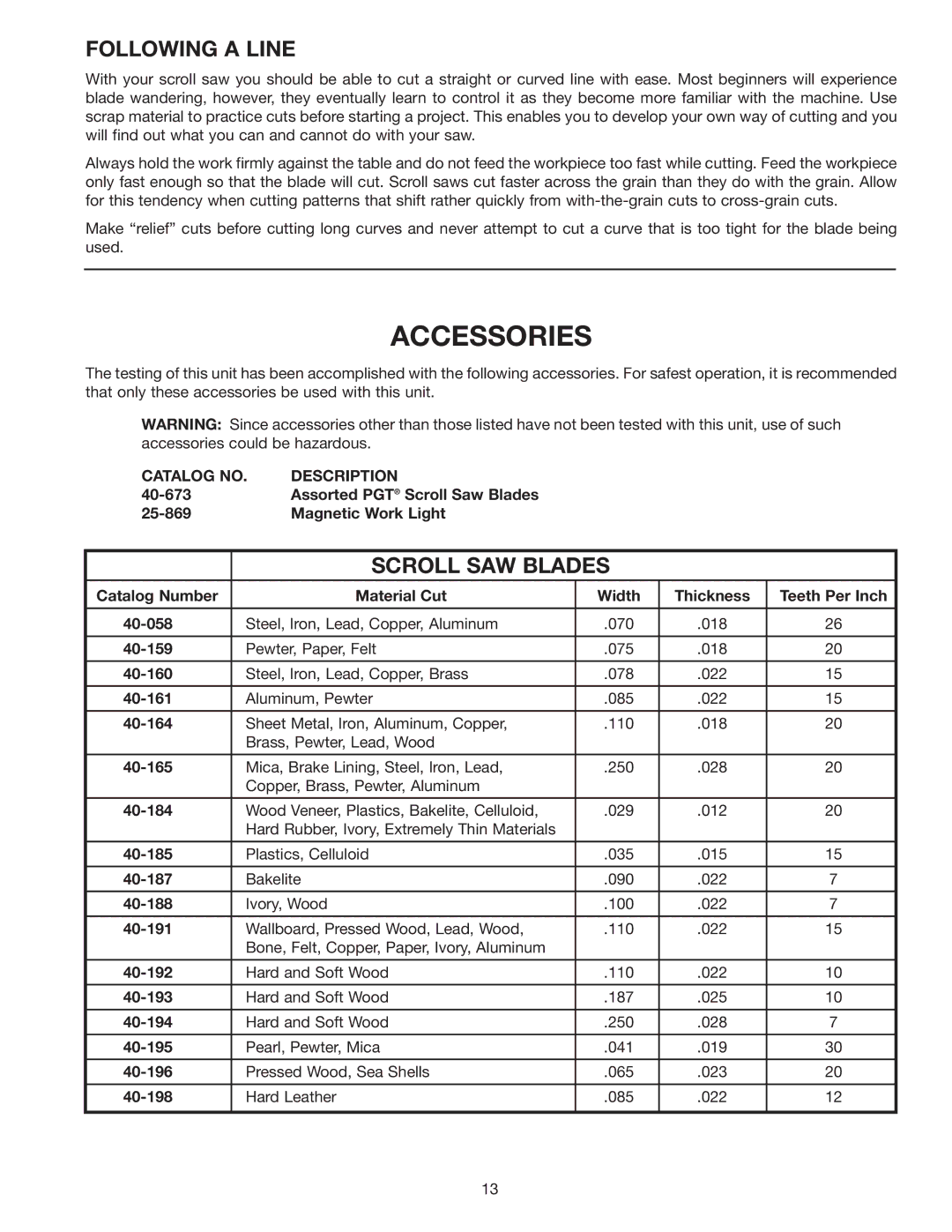

The testing of this unit has been accomplished with the following accessories. For safest operation, it is recommended that only these accessories be used with this unit.

WARNING: Since accessories other than those listed have not been tested with this unit, use of such accessories could be hazardous.

CATALOG NO. | DESCRIPTION |

Assorted PGT® Scroll Saw Blades | |

Magnetic Work Light |

| SCROLL SAW BLADES |

|

| |

Catalog Number | Material Cut | Width | Thickness | Teeth Per Inch |

|

|

|

|

|

Steel, Iron, Lead, Copper, Aluminum | .070 | .018 | 26 | |

|

|

|

|

|

Pewter, Paper, Felt | .075 | .018 | 20 | |

|

|

|

|

|

Steel, Iron, Lead, Copper, Brass | .078 | .022 | 15 | |

|

|

|

|

|

Aluminum, Pewter | .085 | .022 | 15 | |

|

|

|

|

|

Sheet Metal, Iron, Aluminum, Copper, | .110 | .018 | 20 | |

| Brass, Pewter, Lead, Wood |

|

|

|

|

|

|

|

|

Mica, Brake Lining, Steel, Iron, Lead, | .250 | .028 | 20 | |

| Copper, Brass, Pewter, Aluminum |

|

|

|

|

|

|

|

|

| Wood Veneer, Plastics, Bakelite, Celluloid, | .029 | .012 | 20 |

| Hard Rubber, Ivory, Extremely Thin Materials |

|

|

|

|

|

|

|

|

Plastics, Celluloid | .035 | .015 | 15 | |

|

|

|

|

|

Bakelite | .090 | .022 | 7 | |

|

|

|

|

|

Ivory, Wood | .100 | .022 | 7 | |

|

|

|

|

|

Wallboard, Pressed Wood, Lead, Wood, | .110 | .022 | 15 | |

| Bone, Felt, Copper, Paper, Ivory, Aluminum |

|

|

|

|

|

|

|

|

Hard and Soft Wood | .110 | .022 | 10 | |

|

|

|

|

|

Hard and Soft Wood | .187 | .025 | 10 | |

|

|

|

|

|

Hard and Soft Wood | .250 | .028 | 7 | |

|

|

|

|

|

Pearl, Pewter, Mica | .041 | .019 | 30 | |

|

|

|

|

|

Pressed Wood, Sea Shells | .065 | .023 | 20 | |

|

|

|

|

|

| Hard Leather | .085 | .022 | 12 |

|

|

|

|

|

13