ASSEMBLING

TABLE INSERTS

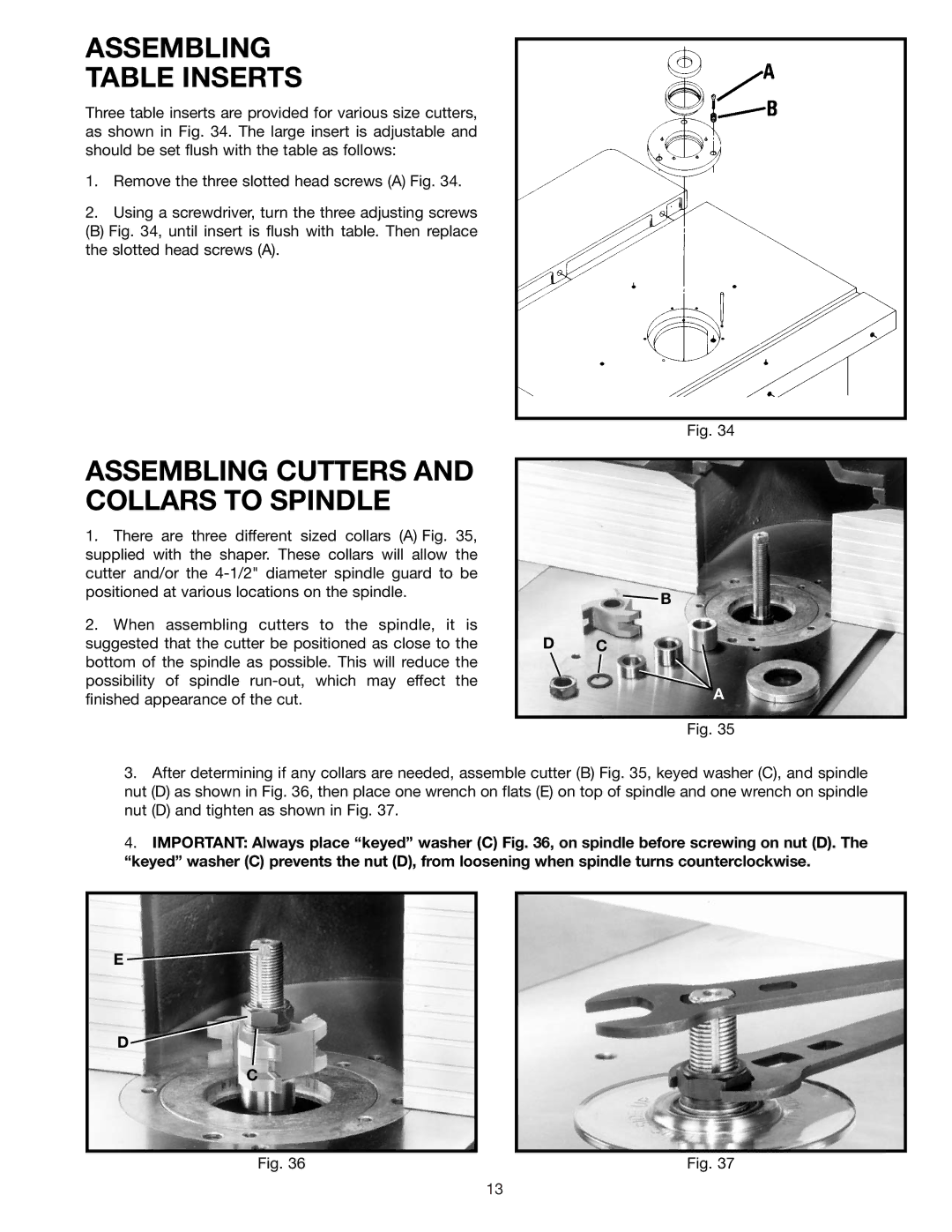

Three table inserts are provided for various size cutters, as shown in Fig. 34. The large insert is adjustable and should be set flush with the table as follows:

1.Remove the three slotted head screws (A) Fig. 34.

2.Using a screwdriver, turn the three adjusting screws

(B) Fig. 34, until insert is flush with table. Then replace the slotted head screws (A).

Fig. 34

ASSEMBLING CUTTERS AND COLLARS TO SPINDLE

1.There are three different sized collars (A) Fig. 35, supplied with the shaper. These collars will allow the cutter and/or the

2.When assembling cutters to the spindle, it is suggested that the cutter be positioned as close to the bottom of the spindle as possible. This will reduce the possibility of spindle

![]() B

B

D C

A

Fig. 35

3.After determining if any collars are needed, assemble cutter (B) Fig. 35, keyed washer (C), and spindle nut (D) as shown in Fig. 36, then place one wrench on flats (E) on top of spindle and one wrench on spindle nut (D) and tighten as shown in Fig. 37.

4.IMPORTANT: Always place “keyed” washer (C) Fig. 36, on spindle before screwing on nut (D). The “keyed” washer (C) prevents the nut (D), from loosening when spindle turns counterclockwise.

E ![]()

D

C

Fig. 36 | Fig. 37 |

13