RAISING AND

LOWERING SPINDLE

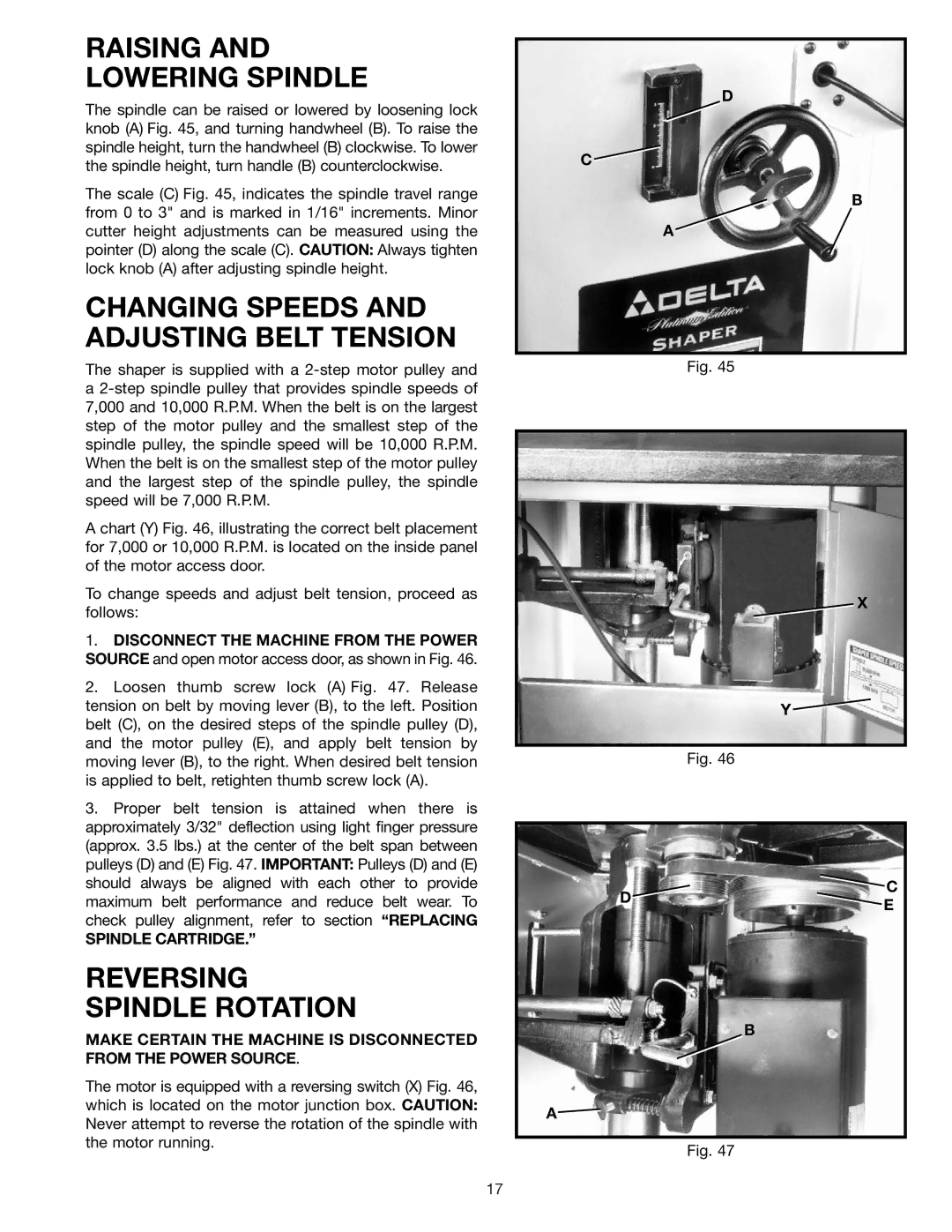

The spindle can be raised or lowered by loosening lock knob (A) Fig. 45, and turning handwheel (B). To raise the spindle height, turn the handwheel (B) clockwise. To lower the spindle height, turn handle (B) counterclockwise.

The scale (C) Fig. 45, indicates the spindle travel range from 0 to 3" and is marked in 1/16" increments. Minor cutter height adjustments can be measured using the pointer (D) along the scale (C). CAUTION: Always tighten lock knob (A) after adjusting spindle height.

CHANGING SPEEDS AND ADJUSTING BELT TENSION

The shaper is supplied with a

A chart (Y) Fig. 46, illustrating the correct belt placement for 7,000 or 10,000 R.P.M. is located on the inside panel of the motor access door.

To change speeds and adjust belt tension, proceed as follows:

1.DISCONNECT THE MACHINE FROM THE POWER SOURCE and open motor access door, as shown in Fig. 46.

2.Loosen thumb screw lock (A) Fig. 47. Release tension on belt by moving lever (B), to the left. Position belt (C), on the desired steps of the spindle pulley (D), and the motor pulley (E), and apply belt tension by moving lever (B), to the right. When desired belt tension is applied to belt, retighten thumb screw lock (A).

3.Proper belt tension is attained when there is approximately 3/32" deflection using light finger pressure (approx. 3.5 lbs.) at the center of the belt span between pulleys (D) and (E) Fig. 47. IMPORTANT: Pulleys (D) and (E) should always be aligned with each other to provide maximum belt performance and reduce belt wear. To check pulley alignment, refer to section “REPLACING

SPINDLE CARTRIDGE.”

REVERSING

SPINDLE ROTATION

MAKE CERTAIN THE MACHINE IS DISCONNECTED FROM THE POWER SOURCE.

The motor is equipped with a reversing switch (X) Fig. 46, which is located on the motor junction box. CAUTION: Never attempt to reverse the rotation of the spindle with the motor running.

D

C ![]()

B

A

Fig. 45

X

Y ![]()

Fig. 46

![]() C

C

D![]() E

E

B

A![]()

Fig. 47

17