SEE-THRU CUTTER GUARD

The

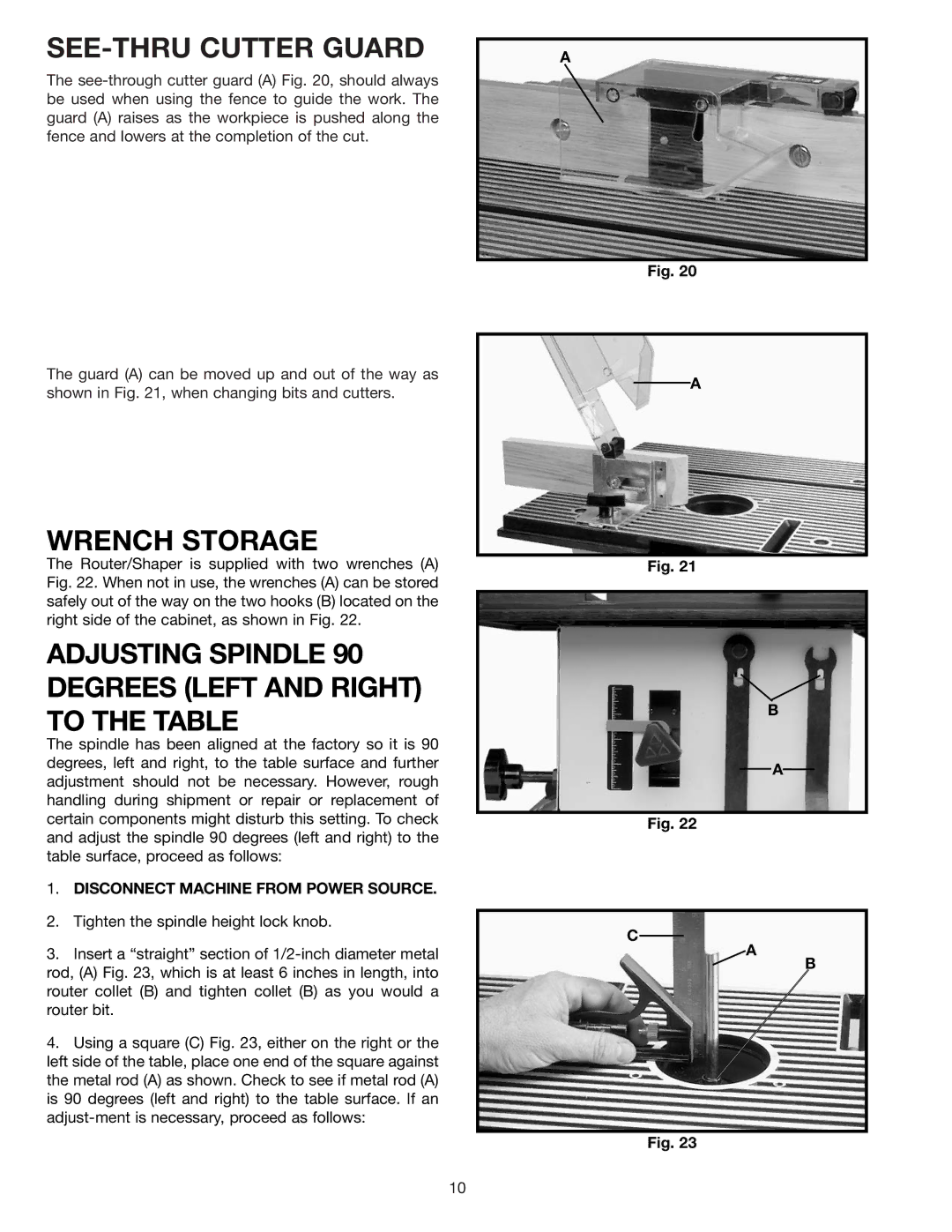

The guard (A) can be moved up and out of the way as shown in Fig. 21, when changing bits and cutters.

WRENCH STORAGE

The Router/Shaper is supplied with two wrenches (A) Fig. 22. When not in use, the wrenches (A) can be stored safely out of the way on the two hooks (B) located on the right side of the cabinet, as shown in Fig. 22.

ADJUSTING SPINDLE 90 DEGREES (LEFT AND RIGHT) TO THE TABLE

The spindle has been aligned at the factory so it is 90 degrees, left and right, to the table surface and further adjustment should not be necessary. However, rough handling during shipment or repair or replacement of certain components might disturb this setting. To check and adjust the spindle 90 degrees (left and right) to the table surface, proceed as follows:

1.DISCONNECT MACHINE FROM POWER SOURCE.

2.Tighten the spindle height lock knob.

3.Insert a “straight” section of

4.Using a square (C) Fig. 23, either on the right or the left side of the table, place one end of the square against the metal rod (A) as shown. Check to see if metal rod (A) is 90 degrees (left and right) to the table surface. If an

A

Fig. 20

A

Fig. 21

B

A

Fig. 22

C

A

B

Fig. 23

10