ADDITIONAL SAFETY RULES FOR

FOR THE ROUTER/SHAPER

![]() WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY

1. | DO NOT OPERATE THIS MACHINE UNTIL it is |

| assembled and installed according to the |

| instructions. |

2. | OBTAIN ADVICE from your supervisor, instructor, |

| or another qualified person if you are not familiar |

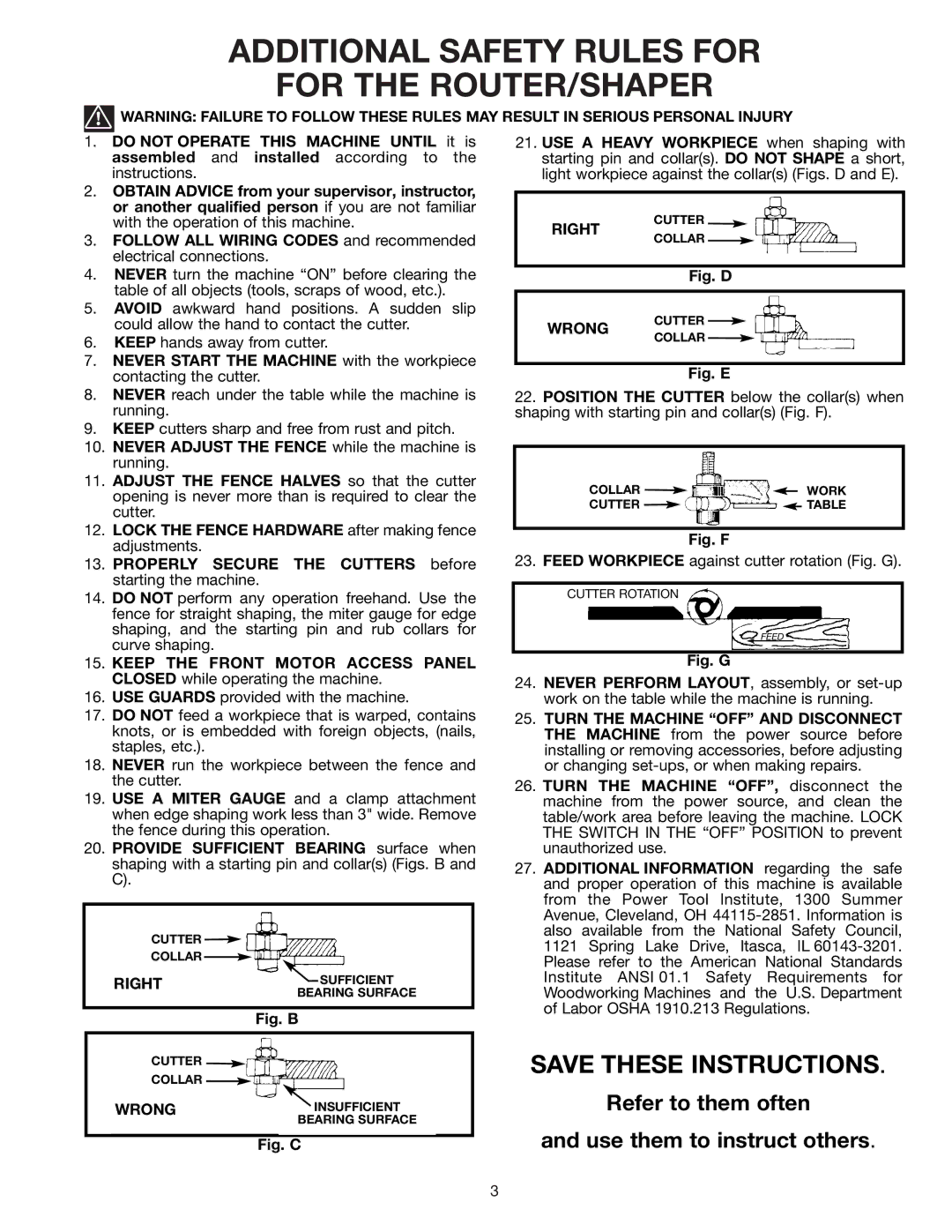

21.USE A HEAVY WORKPIECE when shaping with starting pin and collar(s). DO NOT SHAPE a short, light workpiece against the collar(s) (Figs. D and E).

with the operation of this machine. |

3. FOLLOW ALL WIRING CODES and recommended |

electrical connections. |

RIGHT

CUTTER ![]() COLLAR

COLLAR ![]()

4. | NEVER turn the machine “ON” before clearing the |

| table of all objects (tools, scraps of wood, etc.). |

5. | AVOID awkward hand positions. A sudden slip |

| could allow the hand to contact the cutter. |

6. | KEEP hands away from cutter. |

7. | NEVER START THE MACHINE with the workpiece |

| contacting the cutter. |

WRONG

Fig. D

CUTTER ![]() COLLAR

COLLAR ![]()

Fig. E

8. NEVER reach under the table while the machine is | |

| running. |

9. KEEP cutters sharp and free from rust and pitch. | |

10. | NEVER ADJUST THE FENCE while the machine is |

| running. |

11. | ADJUST THE FENCE HALVES so that the cutter |

| opening is never more than is required to clear the |

| cutter. |

12. | LOCK THE FENCE HARDWARE after making fence |

| adjustments. |

13. | PROPERLY SECURE THE CUTTERS before |

| starting the machine. |

14. | DO NOT perform any operation freehand. Use the |

| fence for straight shaping, the miter gauge for edge |

| shaping, and the starting pin and rub collars for |

| curve shaping. |

15. | KEEP THE FRONT MOTOR ACCESS PANEL |

| CLOSED while operating the machine. |

16. | USE GUARDS provided with the machine. |

17. | DO NOT feed a workpiece that is warped, contains |

| knots, or is embedded with foreign objects, (nails, |

| staples, etc.). |

18. | NEVER run the workpiece between the fence and |

| the cutter. |

19. | USE A MITER GAUGE and a clamp attachment |

| when edge shaping work less than 3" wide. Remove |

| the fence during this operation. |

20. | PROVIDE SUFFICIENT BEARING surface when |

| shaping with a starting pin and collar(s) (Figs. B and |

| C). |

CUTTER![]()

COLLAR![]()

RIGHT | SUFFICIENT |

| BEARING SURFACE |

Fig. B

CUTTER ![]()

COLLAR ![]()

WRONG |

| INSUFFICIENT |

|

|

| BEARING SURFACE |

|

|

|

|

|

| Fig. C | ||

22.POSITION THE CUTTER below the collar(s) when shaping with starting pin and collar(s) (Fig. F).

COLLAR | WORK |

CUTTER | TABLE |

Fig. F

23. FEED WORKPIECE against cutter rotation (Fig. G).

CUTTER ROTATION

FEED

Fig. G

24.NEVER PERFORM LAYOUT, assembly, or

25.TURN THE MACHINE “OFF” AND DISCONNECT THE MACHINE from the power source before installing or removing accessories, before adjusting or changing

26.TURN THE MACHINE “OFF”, disconnect the machine from the power source, and clean the table/work area before leaving the machine. LOCK THE SWITCH IN THE “OFF” POSITION to prevent unauthorized use.

27.ADDITIONAL INFORMATION regarding the safe and proper operation of this machine is available from the Power Tool Institute, 1300 Summer Avenue, Cleveland, OH

SAVE THESE INSTRUCTIONS.

Refer to them often

and use them to instruct others.

3