OPERATING CONTROLS AND ADJUSTMENTS

START/STOP SWITCH

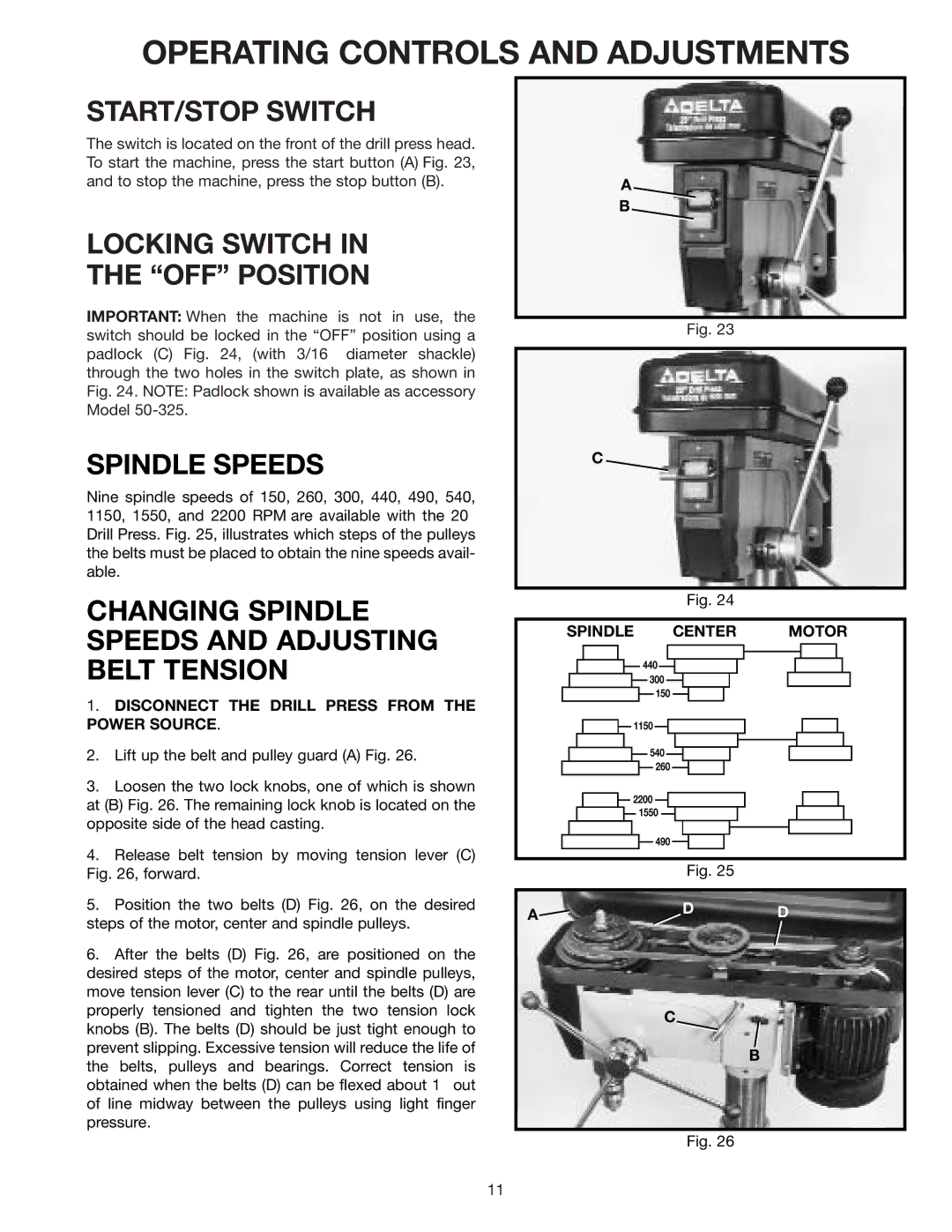

The switch is located on the front of the drill press head. To start the machine, press the start button (A) Fig. 23, and to stop the machine, press the stop button (B).

LOCKING SWITCH IN

THE “OFF” POSITION

IMPORTANT: When the machine is not in use, the switch should be locked in the “OFF” position using a padlock (C) Fig. 24, (with 3/16 diameter shackle) through the two holes in the switch plate, as shown in Fig. 24. NOTE: Padlock shown is available as accessory Model

SPINDLE SPEEDS

Nine spindle speeds of 150, 260, 300, 440, 490, 540, 1150, 1550, and 2200 RPM are available with the 20 Drill Press. Fig. 25, illustrates which steps of the pulleys the belts must be placed to obtain the nine speeds avail- able.

CHANGING SPINDLE SPEEDS AND ADJUSTING BELT TENSION

1.DISCONNECT THE DRILL PRESS FROM THE POWER SOURCE.

2.Lift up the belt and pulley guard (A) Fig. 26.

3.Loosen the two lock knobs, one of which is shown at (B) Fig. 26. The remaining lock knob is located on the opposite side of the head casting.

4.Release belt tension by moving tension lever (C) Fig. 26, forward.

5.Position the two belts (D) Fig. 26, on the desired steps of the motor, center and spindle pulleys.

6.After the belts (D) Fig. 26, are positioned on the desired steps of the motor, center and spindle pulleys, move tension lever (C) to the rear until the belts (D) are properly tensioned and tighten the two tension lock knobs (B). The belts (D) should be just tight enough to prevent slipping. Excessive tension will reduce the life of the belts, pulleys and bearings. Correct tension is obtained when the belts (D) can be flexed about 1 out of line midway between the pulleys using light finger pressure.

A

B

Fig. 23

C

Fig. 24

SPINDLE CENTER MOTOR

440

300

150

1150

540

260

2200

1550

490

Fig. 25

A![]()

![]() D D

D D

C

B

Fig. 26

11