Product Application

Industrial Automation BU, Delta Electronics, Inc.

Case | Application: Delta C2000 Series AC Motor Drive and AFE2000 Active | |||||

Crane (Overhead Travelling Crane) |

|

|

|

| ||

|

|

|

|

| ||

|

|

|

|

|

|

|

Issued by | Solution Center | Date | November, 2010 |

| Pages | 5 |

|

|

|

|

|

|

|

Applicable to | C2000 series AC motor drive, AFE2000 series active |

|

| |||

|

|

|

|

|

|

|

| crane, hoist, Delta AC motor drive, | |||||

Key words | reliability, AFE2000 active | |||||

| fast braking, brake resistor, current control PWM converter, switch rectifier, | |||||

|

|

|

|

|

|

|

Introduction |

|

|

|

|

|

|

A bridge crane (also known as an overhead travelling crane) finds wide application in warehouses, factories, docks, open storage yards, and more. A

Application

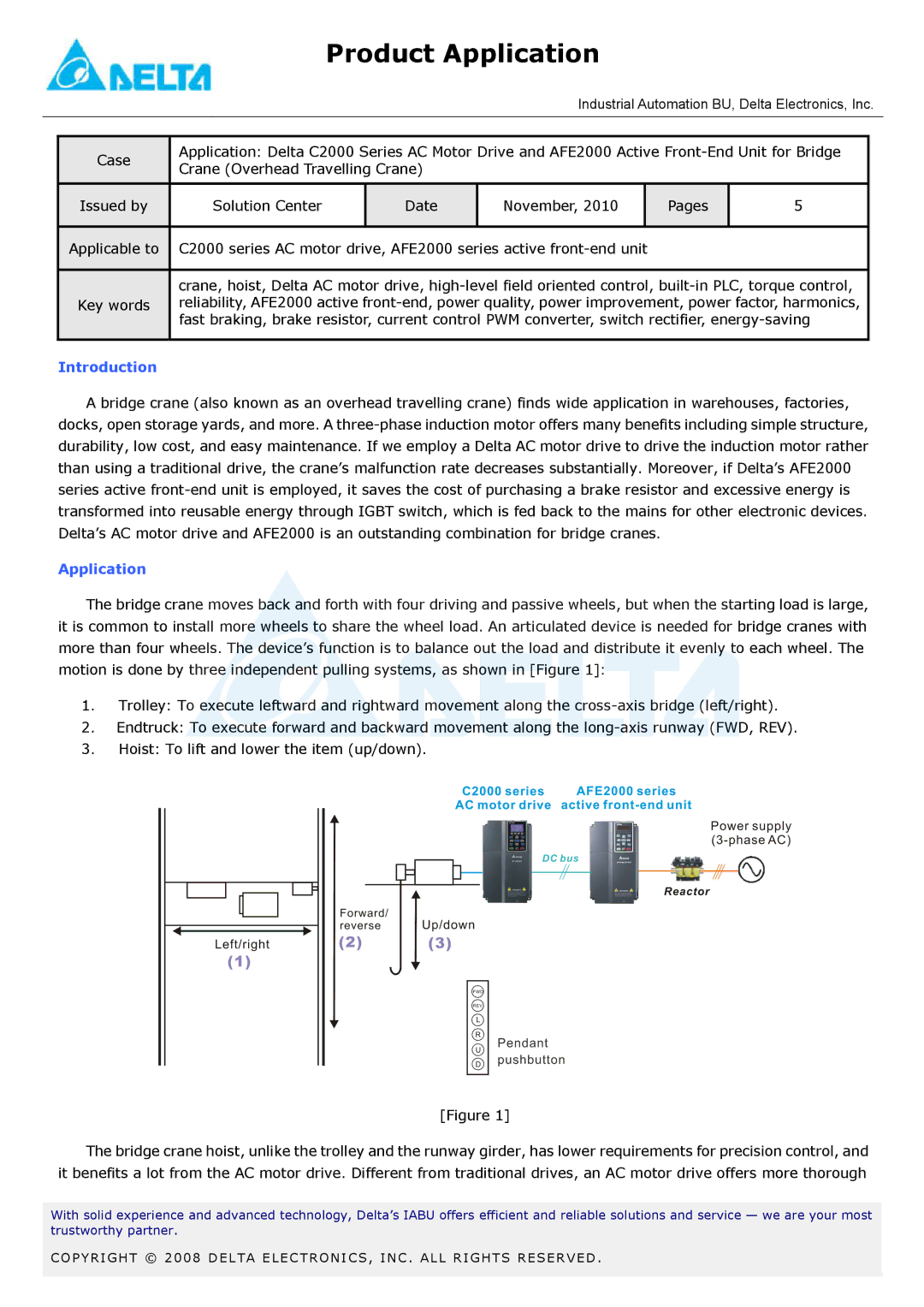

The bridge crane moves back and forth with four driving and passive wheels, but when the starting load is large, it is common to install more wheels to share the wheel load. An articulated device is needed for bridge cranes with more than four wheels. The device’s function is to balance out the load and distribute it evenly to each wheel. The motion is done by three independent pulling systems, as shown in [Figure 1]:

1.Trolley: To execute leftward and rightward movement along the

2.Endtruck: To execute forward and backward movement along the

3.Hoist: To lift and lower the item (up/down).

[Figure 1]

The bridge crane hoist, unlike the trolley and the runway girder, has lower requirements for precision control, and it benefits a lot from the AC motor drive. Different from traditional drives, an AC motor drive offers more thorough

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC . ALL RIGHTS RESERVED .

- 1 -