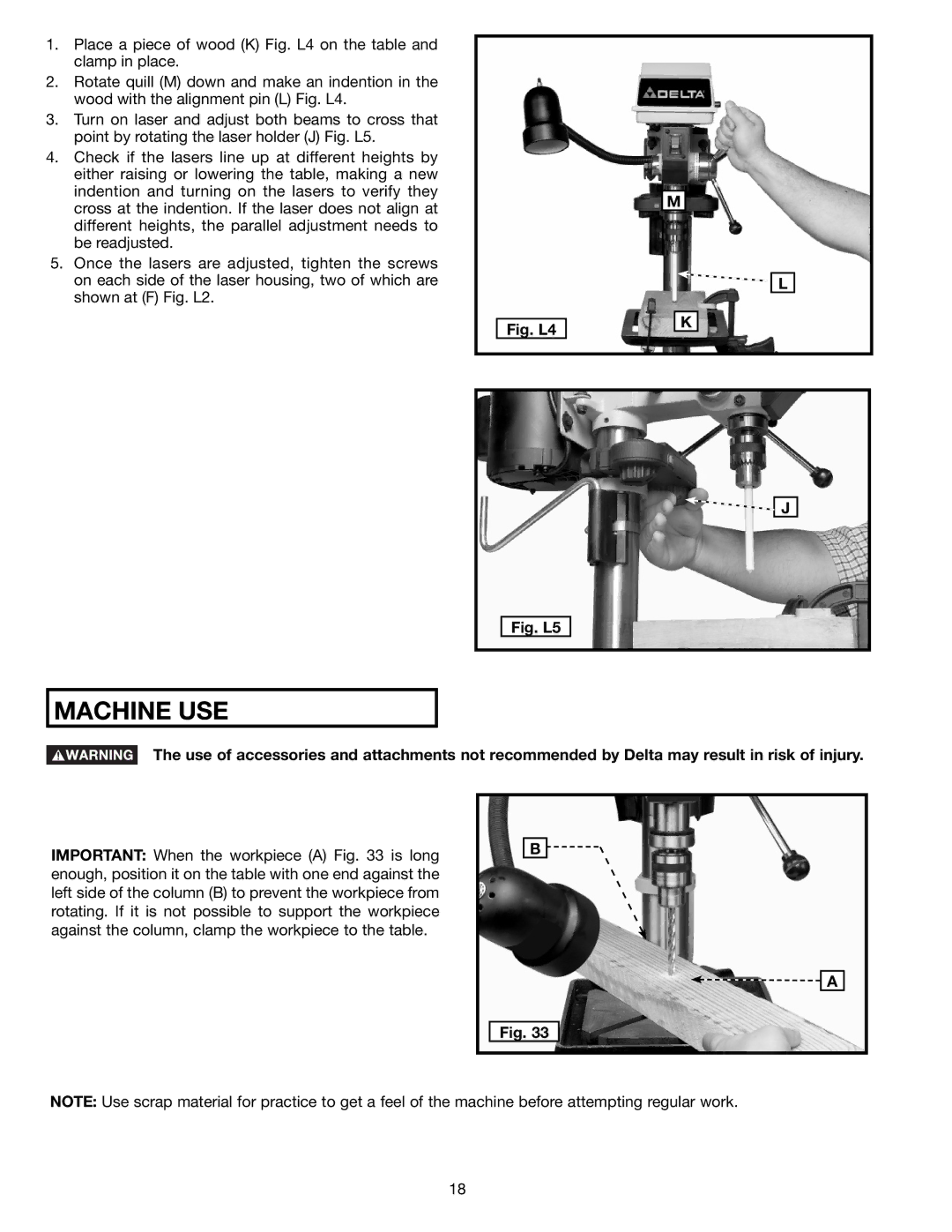

1.Place a piece of wood (K) Fig. L4 on the table and clamp in place.

2.Rotate quill (M) down and make an indention in the wood with the alignment pin (L) Fig. L4.

3.Turn on laser and adjust both beams to cross that point by rotating the laser holder (J) Fig. L5.

4.Check if the lasers line up at different heights by either raising or lowering the table, making a new indention and turning on the lasers to verify they cross at the indention. If the laser does not align at different heights, the parallel adjustment needs to be readjusted.

5.Once the lasers are adjusted, tighten the screws on each side of the laser housing, two of which are shown at (F) Fig. L2.

M

L

|

| K | |

Fig. L4 | |||

|

|

![]() J

J

Fig. L5

MACHINE USE

The use of accessories and attachments not recommended by Delta may result in risk of injury.

B ![]()

![]()

![]() A

A

Fig. 33

NOTE: Use scrap material for practice to get a feel of the machine before attempting regular work.

18